Universal coke flowing knife cleaning device for coke oven machinery and using method thereof

A cleaning device and mechanical technology, applied in coke ovens, unloading devices, furnace prevention/removal of fouling, etc., can solve problems such as harmful waste, and achieve the effect of reducing maintenance costs and improving cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

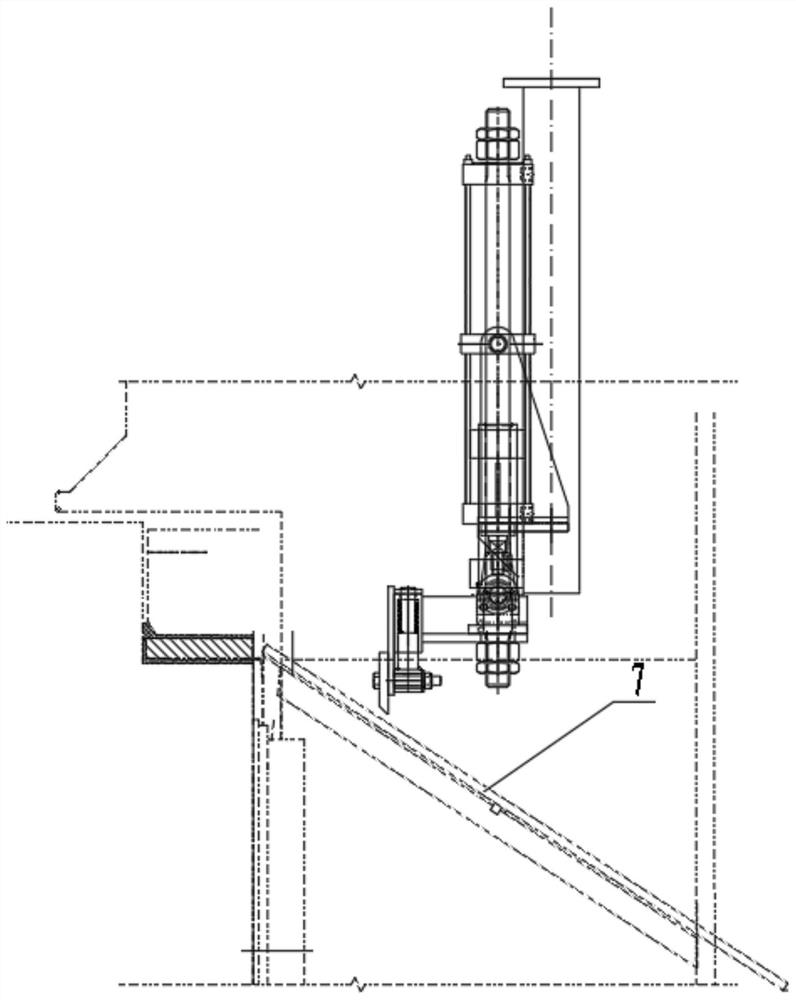

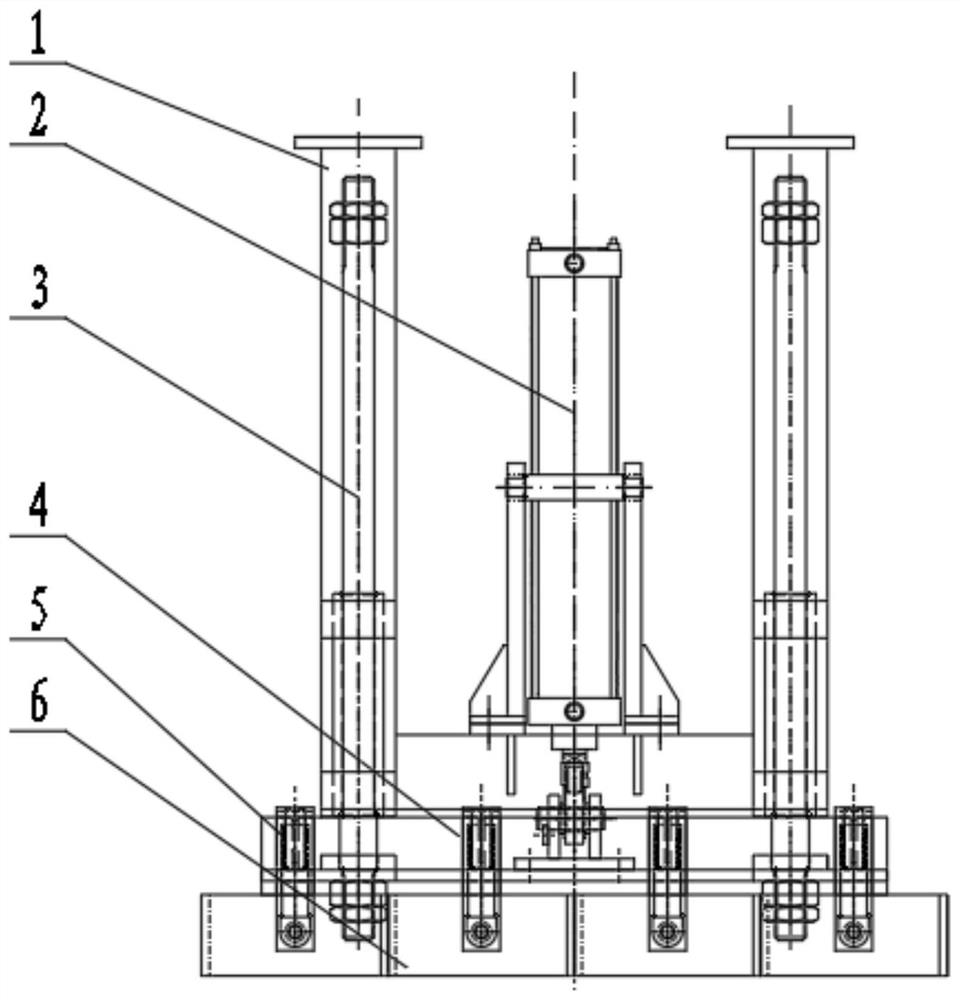

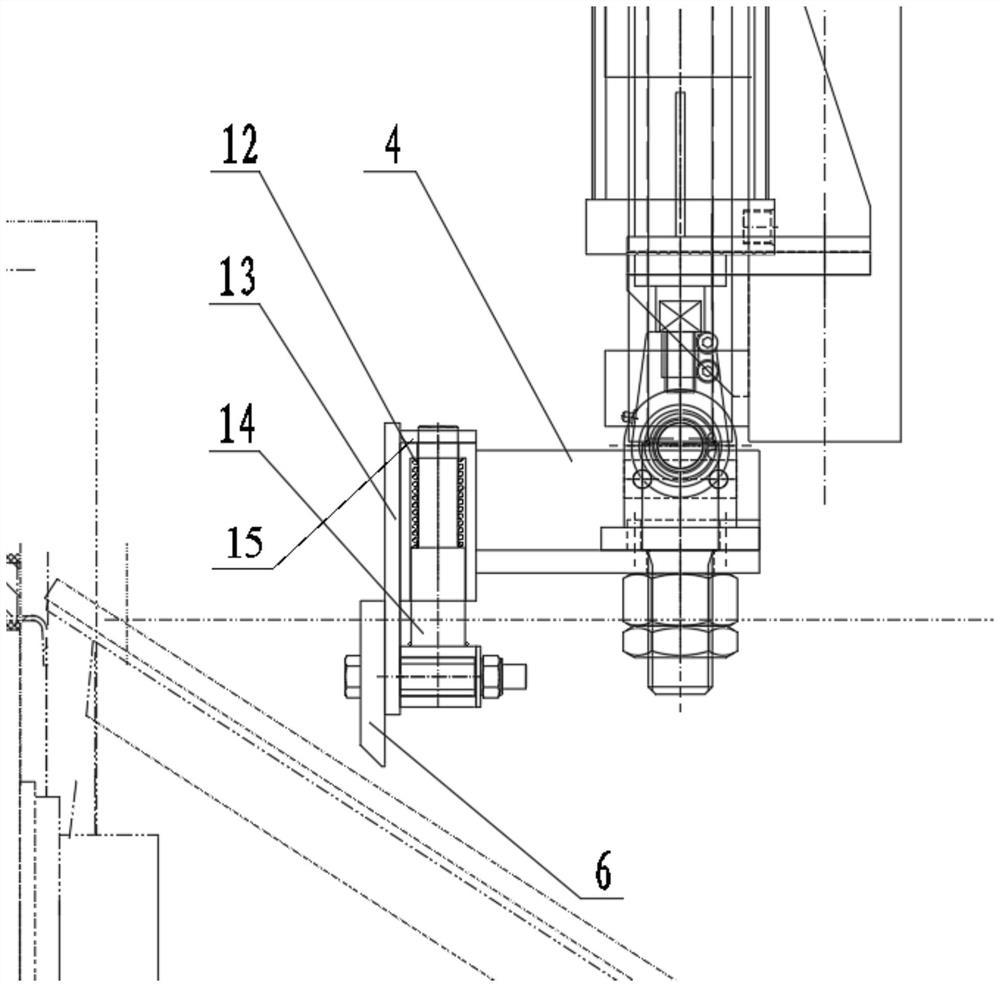

[0041] Such as Figure 1-5 As shown, the present invention provides a common cleaning device for coke oven machinery, which is characterized in that it includes: a support part, a cylinder part and a scraper part, the support part is a fixed installation frame 1, and the fixed installation frame 1 is a U-shaped frame, and the two longitudinal support columns of the fixed installation frame 1 are respectively provided with guide rods 3, the guide rods 3 are smooth cylindrical structures, and the upper and lower ends of the guide rods 3 are provided with threaded structures, The guide rod 3 is installed on the fixed installation frame through a nut; the cylinder part includes a cylinder bracket and a cylinder 2, and the cylinder 2 is installed on the fixed installation frame 1 through the cylinder bracket, and the cylinder bracket It is an airfoil bracket installed on both sides of the cylinder 2; the cylinder 2 is a single push rod cylinder, and the cylinder 2 is installed at t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap