Gridding cloth external thermal insulation fixing system

A fixed system and grid cloth technology, applied in the field of passive houses, can solve the problems of limited alkali-resistant glass fiber resistance to alkali corrosion, affecting the service life of the external thermal insulation surface layer, etc., so as to reduce the difficulty of construction and realize two-dimensional adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

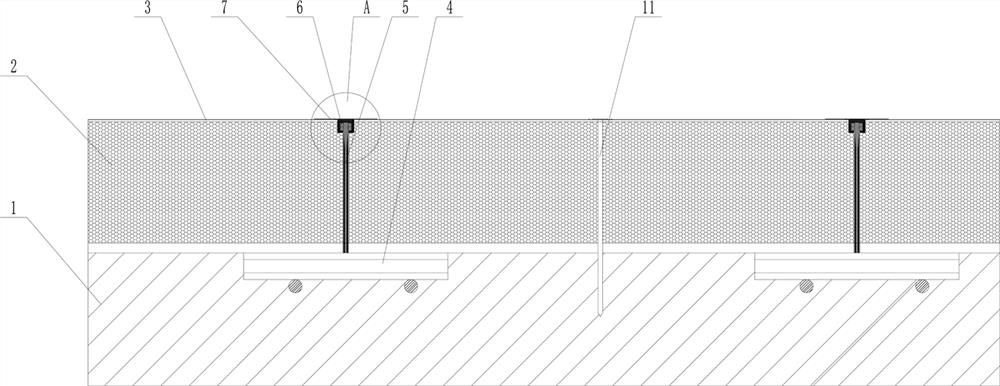

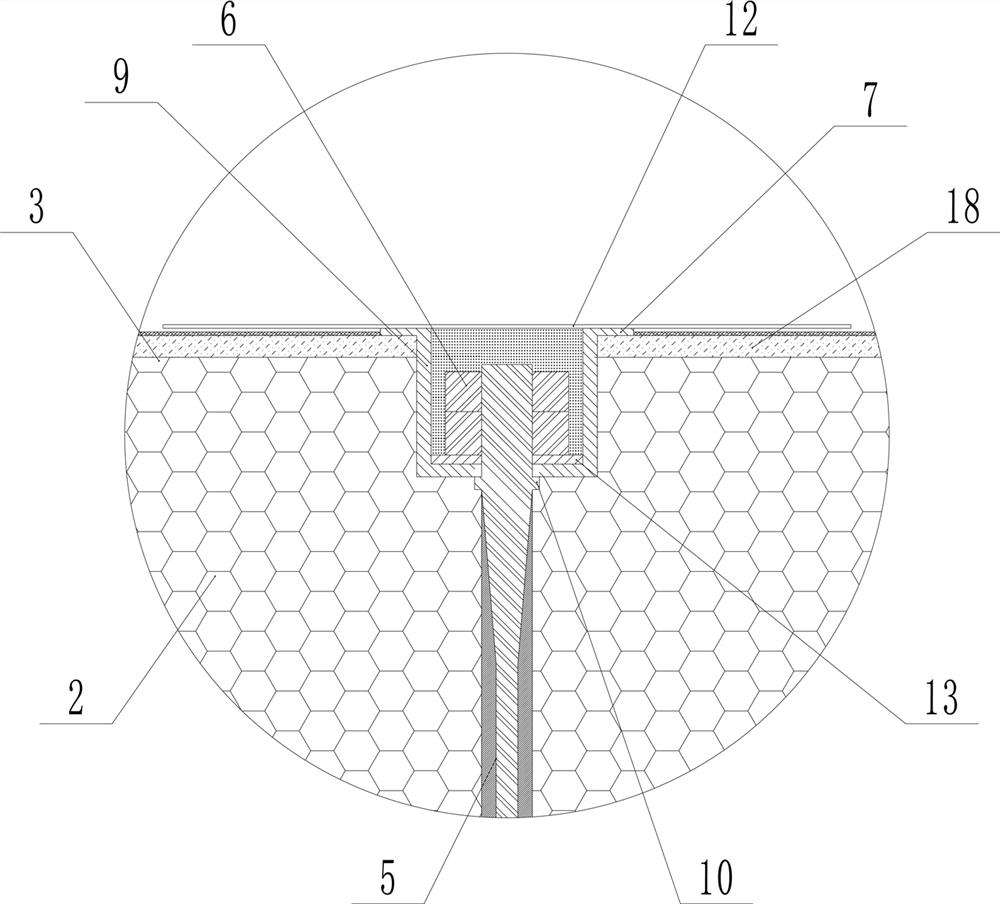

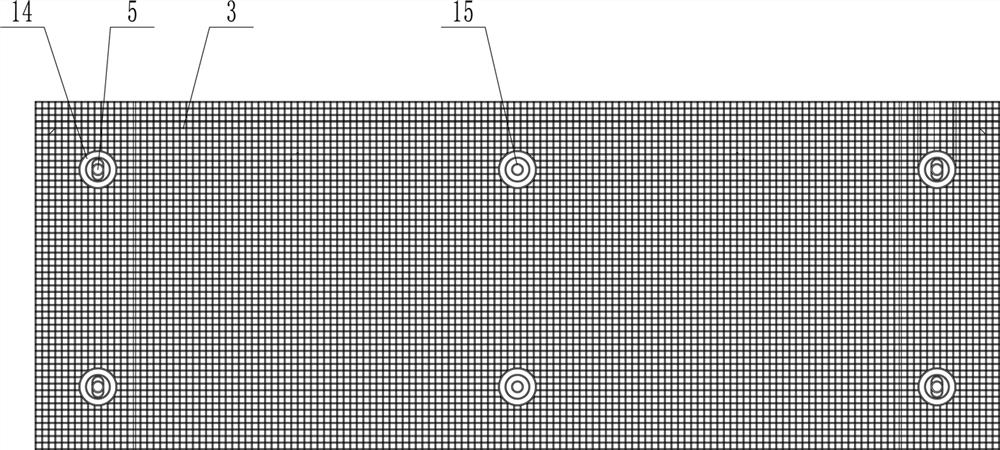

[0028] Such as Figure 1-Figure 3 As shown, a grid cloth external thermal insulation fixing system includes a structural main body 1, a thermal insulation block 2, a grid cloth 3 made of basalt fiber composite material, an anchor rod 11 and a pull rod mechanism. The thermal insulation block 2 is attached to the structure On the outer surface of the main body 1 , the mesh cloth 3 is pasted on the outer surface of the thermal insulation block 2 , and the structural main body 1 , the thermal insulation block 2 and the mesh cloth 3 are fixed by anchor rods 11 .

[0029] The pull rod mechanism includes a horizontal adjustment base 4 pre-embedded in the outer surface of the main body of the structure, a pull rod 5, a nut 6 and a pressure piece 7 arranged at the outer end of the pull rod 5, and the horizontal adjustment base 4 is a channel-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com