Thermographic inspection for tape layup machines

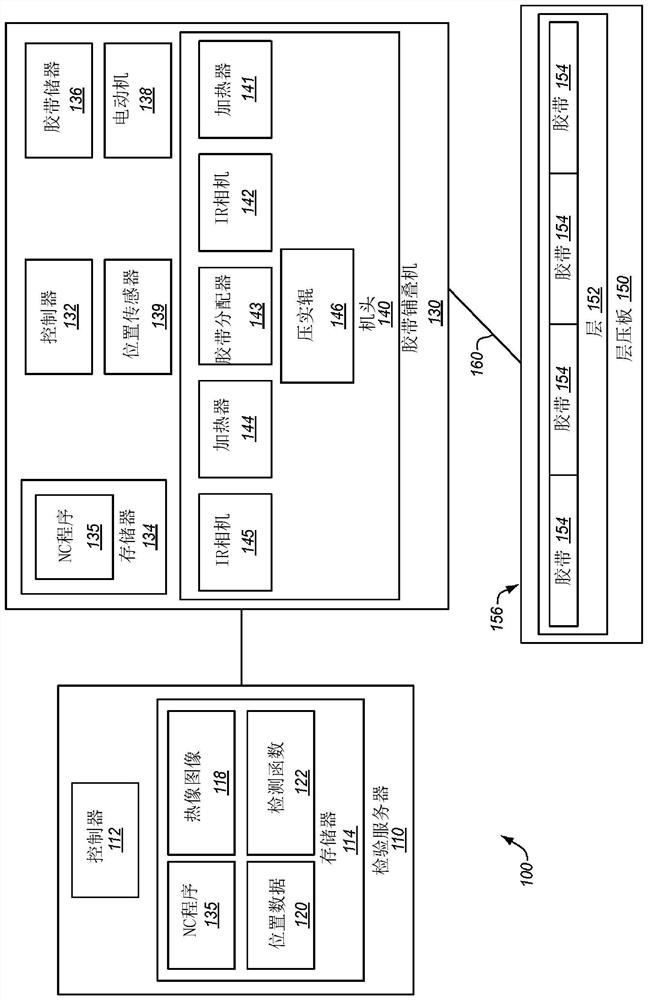

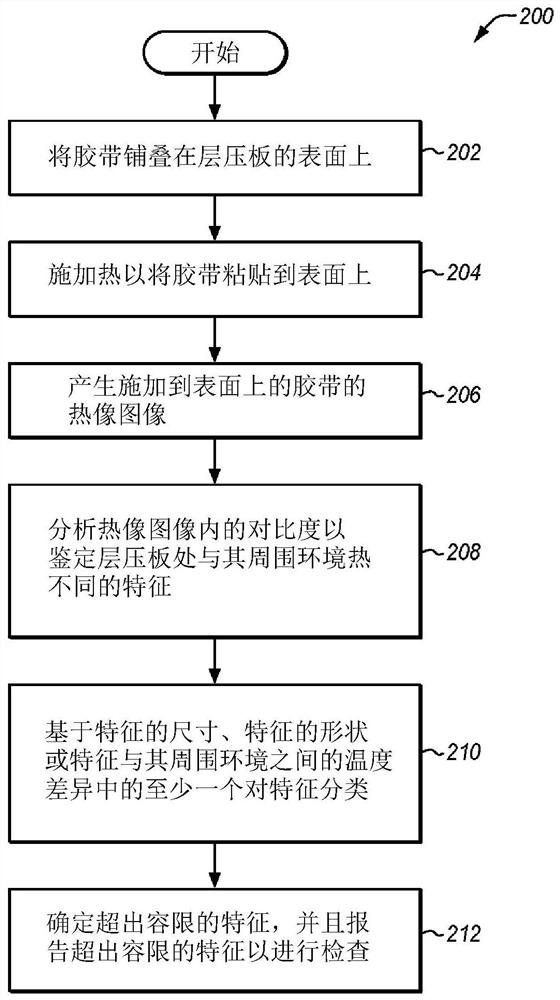

A tape, lay-up technology used in manufacturing to solve the problem of wasting resources, time and labor, reworking or discarding composite parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

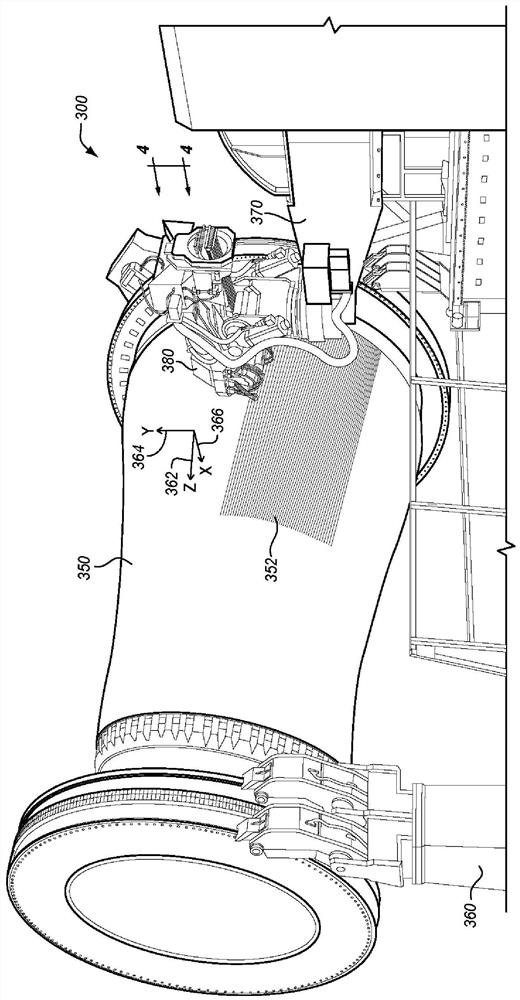

[0321] Referring more specifically to the accompanying drawings, it may be found at, for example, Figure 20 aircraft manufacturing and servicing in method 2000 and Figure 21 Embodiments of the present disclosure are described in the context of the illustrated aircraft 2002 . During pre-production, method 2000 may include specification and design 2004 of aircraft 2002 and material procurement 2006 . During production, component and subassembly manufacturing 2008 and system integration 2010 of the aircraft 2002 are performed. Thereafter, the aircraft may be certified in 2002 and delivered in 2012 for entry into service in 2014. During customer use, aircraft 2002 is scheduled for maintenance and service 2016 to perform routine work (which may also include refurbishment, reconfiguration, refurbishment, etc.). Any one or more suitable phases of production and service that may be described in method 2000 (e.g., specification and design 2004, material procurement 2006, component a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com