Method and machine for making articles for use in surface treating appliances

A surface treatment and machine technology, applied in thin material treatment, household appliances, applications, etc., can solve the problems of high cost, error-prone, and inability to provide felt uniform paste, etc., and achieve the effect of simplifying manufacturing complexity and high material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

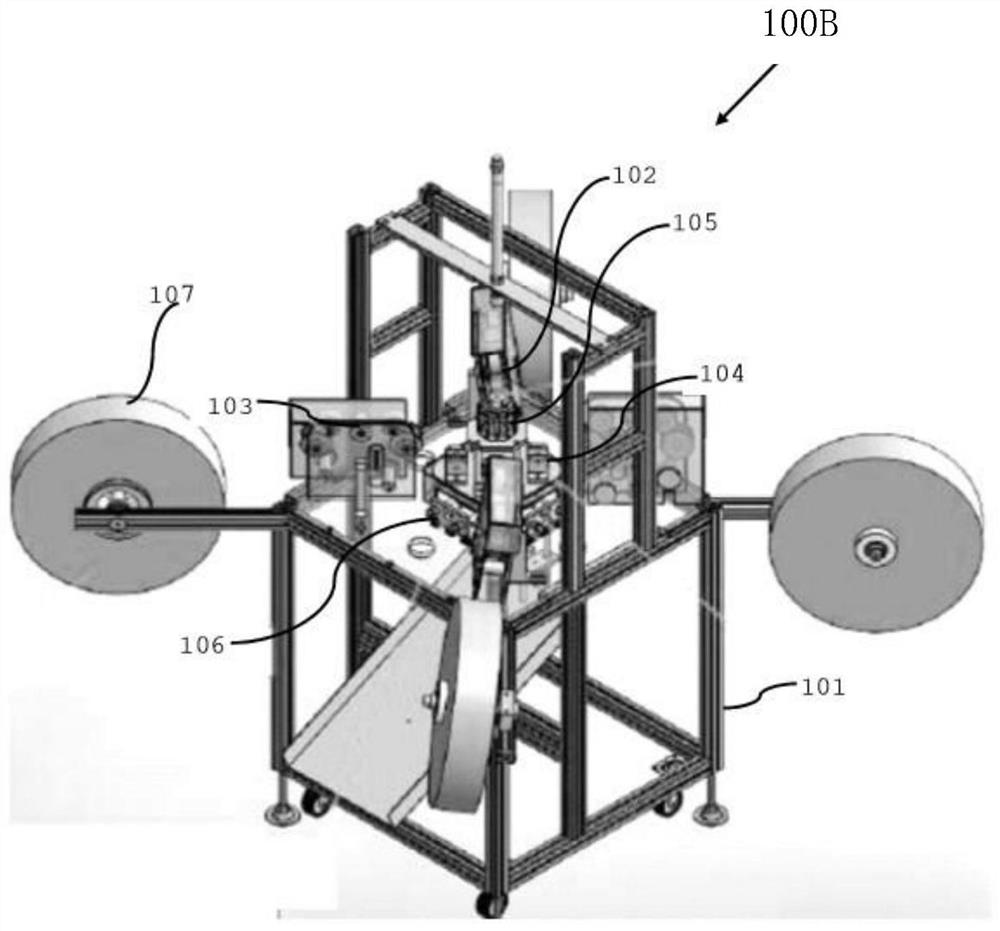

[0024] Various embodiments of the present invention provide a method of making an article for use in a surface treating appliance and a machine thereof.

[0025] In a related embodiment, the article is an automatic roller brush bar for a surface treatment appliance, such as a vacuum cleaner, and the invention relates to a machine and a method for making the same.

[0026] However, it will be apparent to those of ordinary skill in the art that modified manufacturing methods and machines may also be applied to equivalent components in other surface treating appliances. The term "surface treating appliance" includes vacuum cleaners and other related appliances within the scope of the present invention. It extends to a wide range of implements capable of picking up material from surfaces and machines that apply material to surfaces, such as polishers, shampooers, packaging machines, and the like.

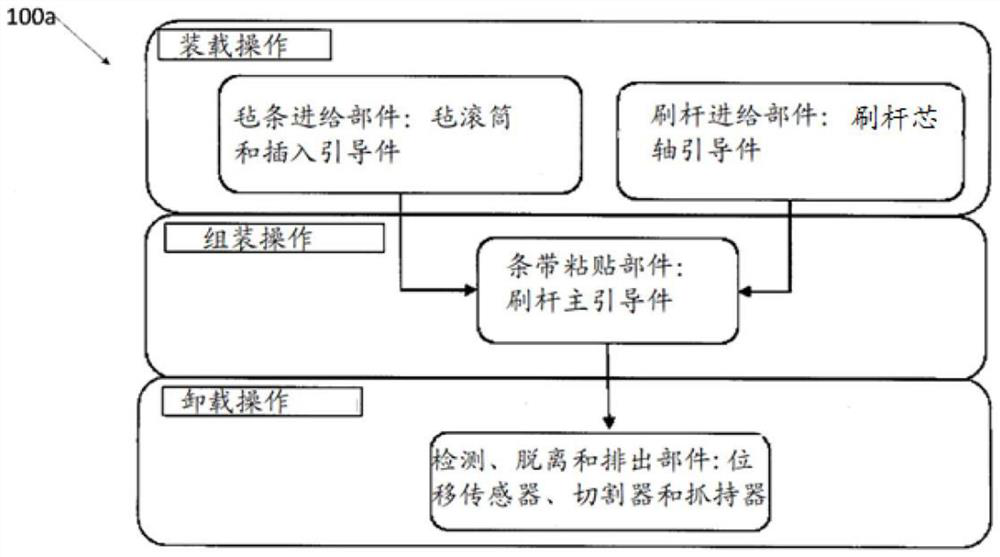

[0027] refer to Figure 1A In block diagram 100a, the present invention can be bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com