A method and device for butt jointing of plates in internal high pressure forming

A technology of internal high-pressure forming and docking devices, which is applied in the field of stamping devices, can solve the problems of fatigue strength limitation of welding joints, health hazards of workers, and reduction of material corrosion resistance, so as to protect production workers, save process time, The effect of improving the ability to resist bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

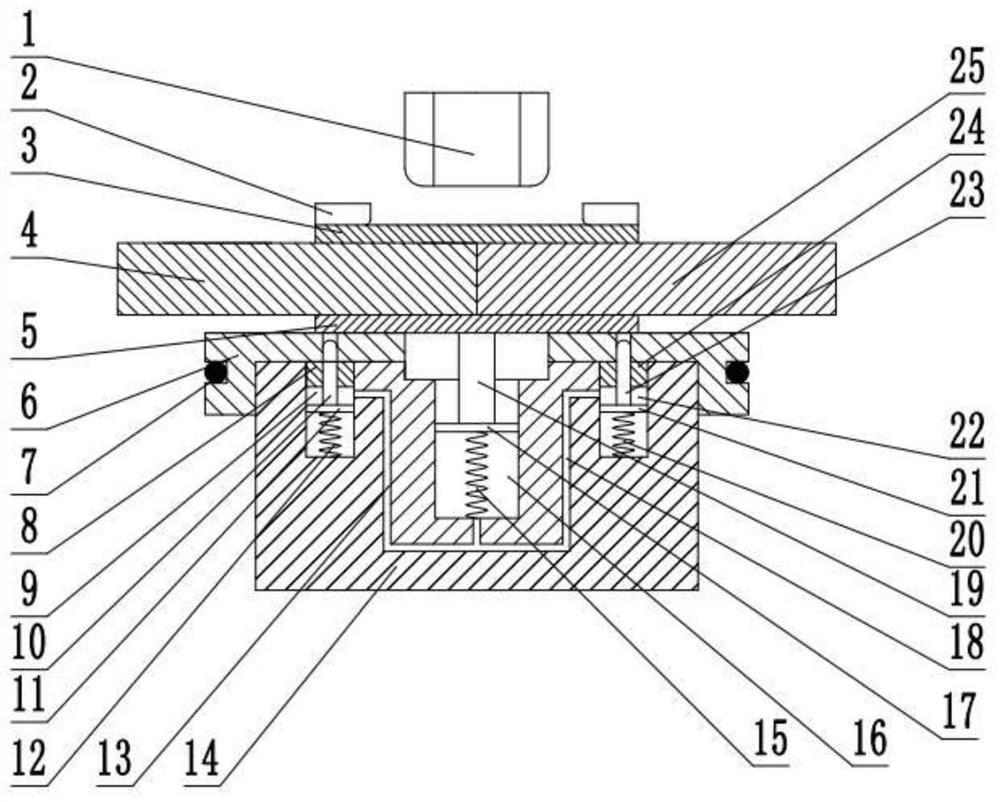

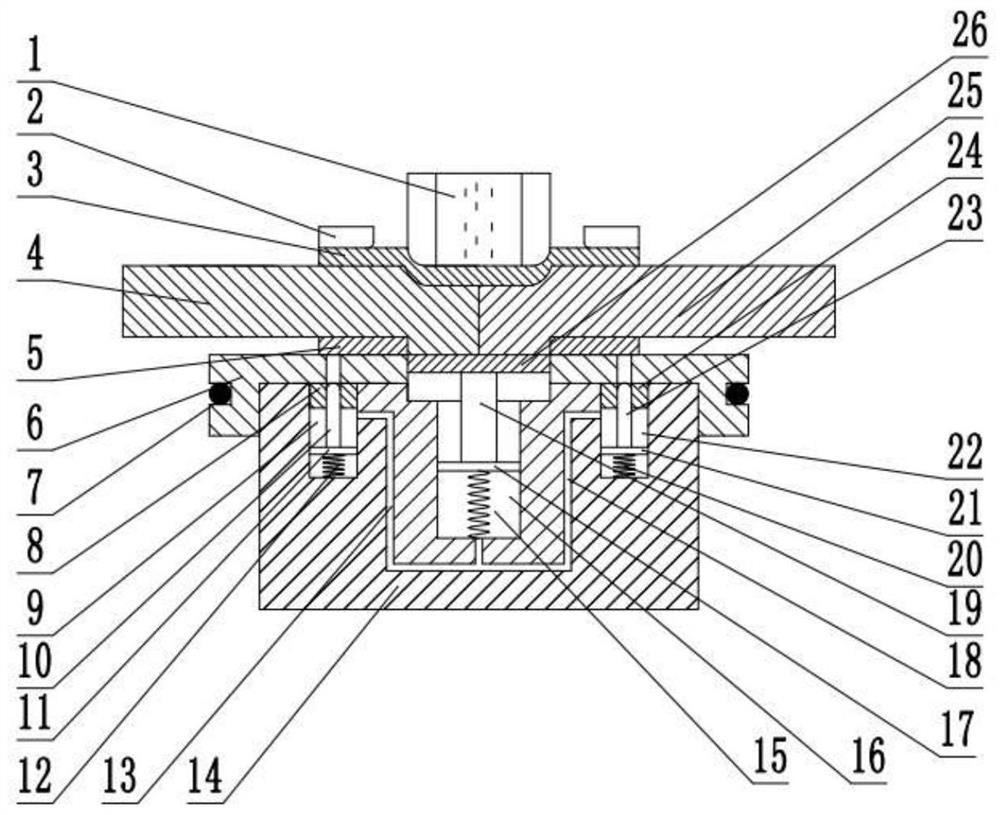

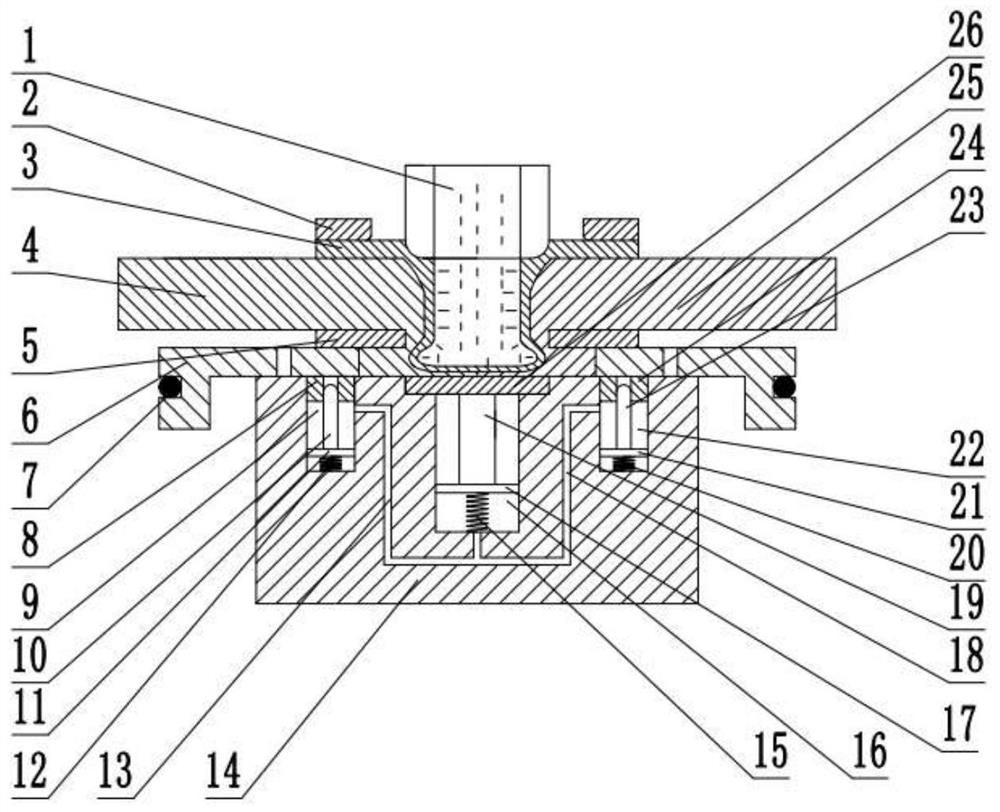

[0046] The inner high pressure forming plate docking device is activated, the blank holder 2 applies a blank holder force to the upper auxiliary plate 3, and the punch 1 moves downward; after the punch 1 contacts the upper auxiliary plate 3, high pressure liquid is injected, and the upper auxiliary plate 3, the A butted plate 4 and the second butted plate 25 are squeezed and deformed, and the lower auxiliary plate 5 is cut into a circular waste 26 under the action of the upper pressure and the central hole of the split die 6; the high-pressure liquid in the punch 1 continues When pressure is applied, the circular waste 26 continues to squeeze the piston rod 19 downward, the piston 17 under the piston rod 19 squeezes the hydraulic chamber 16, and the liquid in the hydraulic chamber 16 flows to the first auxiliary hydraulic chamber 9 through the pipeline 13 and the pipeline 18 and the second auxiliary hydraulic chamber 22 , the liquid in the first auxiliary hydraulic chamber 9 ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com