3D (three-dimensional) shell fabric, three-dimensional fabric product and manufacturing method of 3D shell fabric

A manufacturing method and fabric technology, applied to fabrics of new technology and their application fields, can solve problems such as inability to form shapes, geometric progression of costs, and no surface details, and achieve improved production efficiency, high production efficiency and quality consistency. , the effect of enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

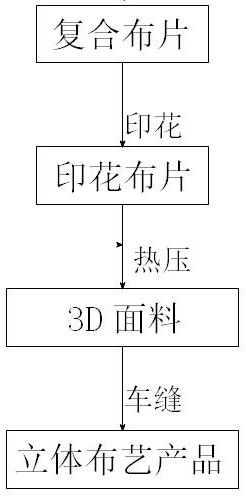

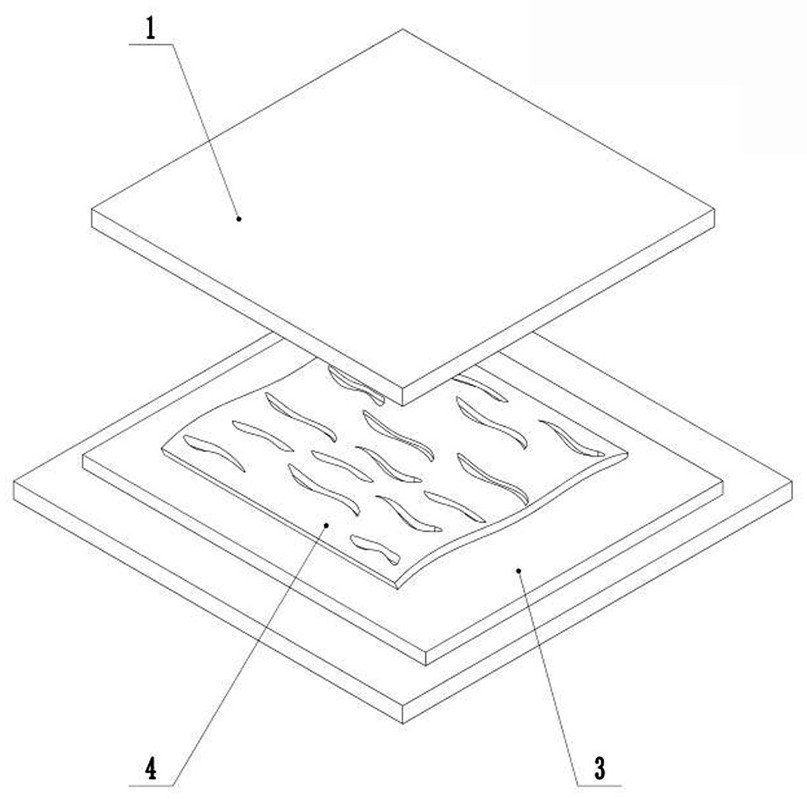

[0028] The process flow of the three-dimensional cloth art product manufacturing method of the present embodiment is as follows: figure 1 As shown, the pattern is printed on the surface fabric with a composite cloth sheet including surface fabric, foam layer and bottom yarn. Silicone foam boards and metal molds are respectively arranged on both sides of the composite cloth sheet. The shape of the metal mold after heating Matching the printed pattern and concave-convex surface, the composite cloth sheet and the silicone foam board are extruded by a heated metal mold, the foam layer is melted and compressed according to the pattern outline of the printed surface layer to form a concave part, and the rest of the foam layer and the fabric are retained to form Convex.

[0029] When the foam layer is made of 8mm thick sponge, the working temperature of the metal mold is 210 degrees Celsius, the pressing pressure is 314kg, the thickness of the silicone foam board is 12mm, and the pre...

Embodiment 2

[0033] Such as image 3 As shown, the 3D embossing equipment includes a mold 5, a hydraulic cylinder 6, a pressing plate 7 and a frame. As the supporting structure of the whole 3D embossing equipment, the frame is fixedly installed on the ground. The upper end of the rack is provided with a horizontal workbench. Two linear guide rails 9 are fixedly installed on the horizontal workbench, and the two linear guide rails 9 are parallel to each other. Two linear guide rails 9 are respectively provided with slide tables. The slide table can move back and forth along the linear guide rail 9. The base plate of mold 5 is fixedly installed on the slide table. The mold 5 can move along the linear guide rail 9 together with the slide table. The press plate 7 is arranged above the mold 5 . The upper end of the pressing plate 7 is connected with the piston rod of the hydraulic cylinder 6 . Driven by the hydraulic cylinder 6, the piston rod drives the pressing plate 7 to move up and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com