An automatic laminating device for medical trays

A laminating device and automatic technology, applied in the directions of packaging material feeding device, packaging, transportation and packaging, etc., can solve the problems of unsightly appearance, many people, inclination, etc., and achieve the effect of large volume and manpower saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

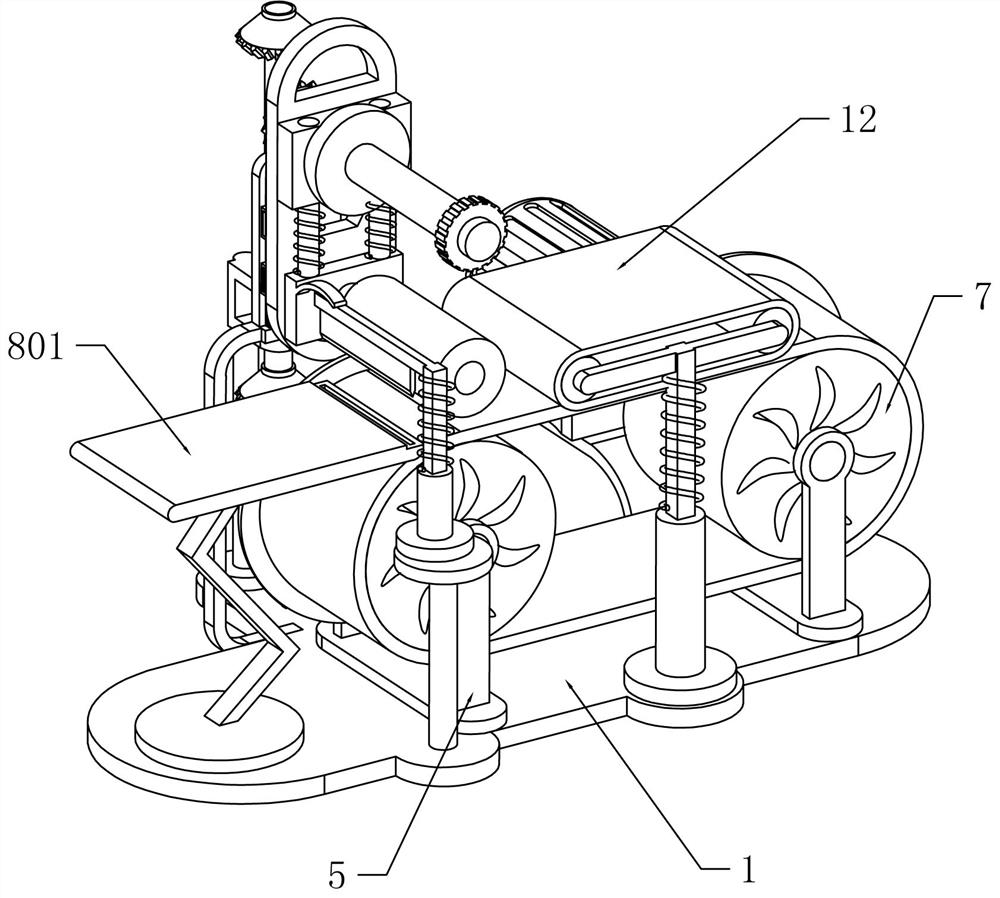

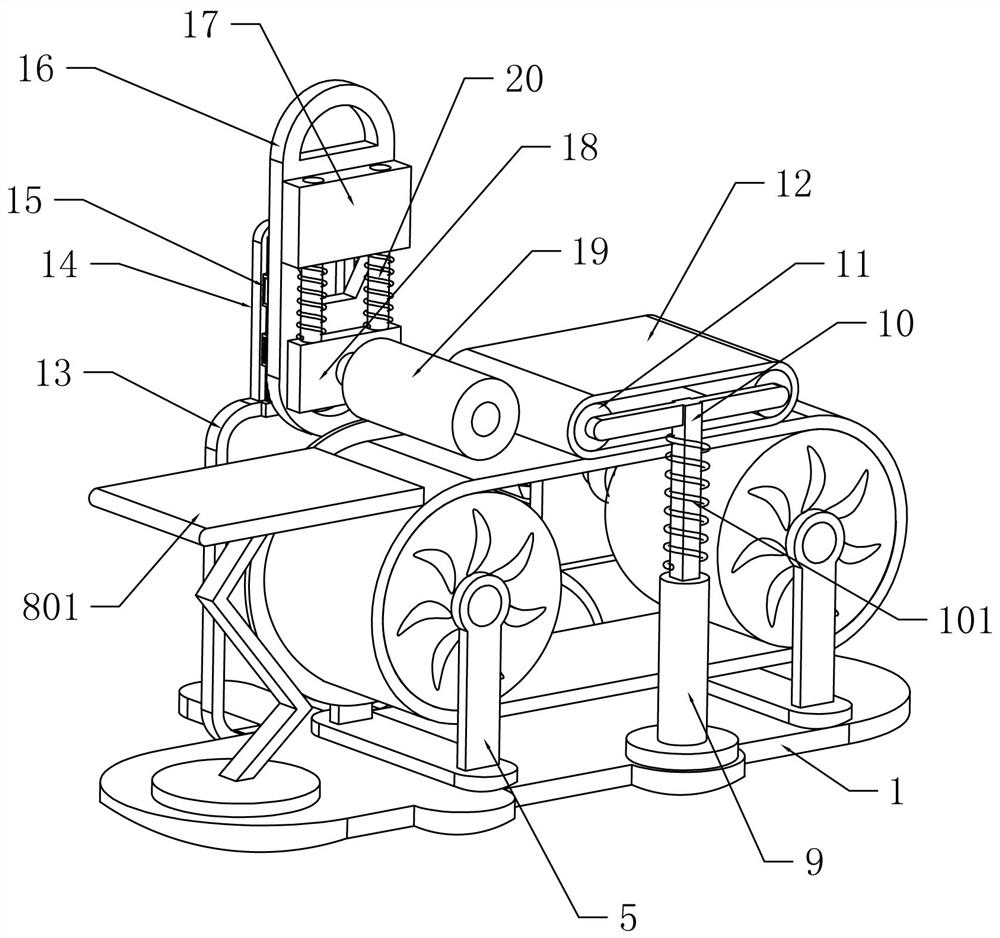

[0065] An automatic film covering device for medical trays, such as Figure 1-5 As shown, it includes a bottom plate 1, a motor base 2, a servo motor 3, a coupling 4, a conveyor belt assembly, a transition assembly, and a pressing assembly. On the seat 2, the coupling 4 is fixed to the output shaft of the servo motor 3, the conveyor belt assembly is fixed on the top of the bottom plate 1, the conveyor belt assembly is connected to the coupling 4 and is located in front of the motor seat 2, and the transition assembly is fixed on the bottom plate 1. On the top of the conveyor belt assembly, the pressing assembly is fixed on the bottom plate 1 and connected with the conveyor belt assembly.

[0066] When laminating the medical tray, manually put the medical tray on the conveyor belt assembly, start the servo motor 3, the servo motor 3 drives the conveyor belt assembly to run, the medical tray moves from right to left along the conveyor belt assembly, and the medical tray transiti...

Embodiment 2

[0068] On the basis of Example 1, such as Figure 1-3As shown, the conveyor belt assembly includes a support frame 5, a rotating shaft 6, a transmission wheel 7, a conveyor belt 8, and a support plate 801. There are two U-shaped support frames 5, which are respectively fixed on the upper left and right positions of the bottom plate 1, and the right side supports The rear side of the frame 5 is opposite to the shaft coupling 4, and the rotating shaft 6 is two rotating shafts connected to the support frame 5 on the left and right sides respectively. A transmission wheel 7 is socketed, and two transmission wheels 7 are arranged in the support frame 5 respectively. The conveyor belt 8 bypasses the two transmission wheels 7 .

[0069] When the servo motor 3 is started to rotate, the shaft coupling 4 drives the rotating shaft 6 to rotate, and the transmission wheel 7 drives the conveyor belt 8 to start transmission, so that the conveyor belt 8 drives another transmission wheel 7 to ...

Embodiment 3

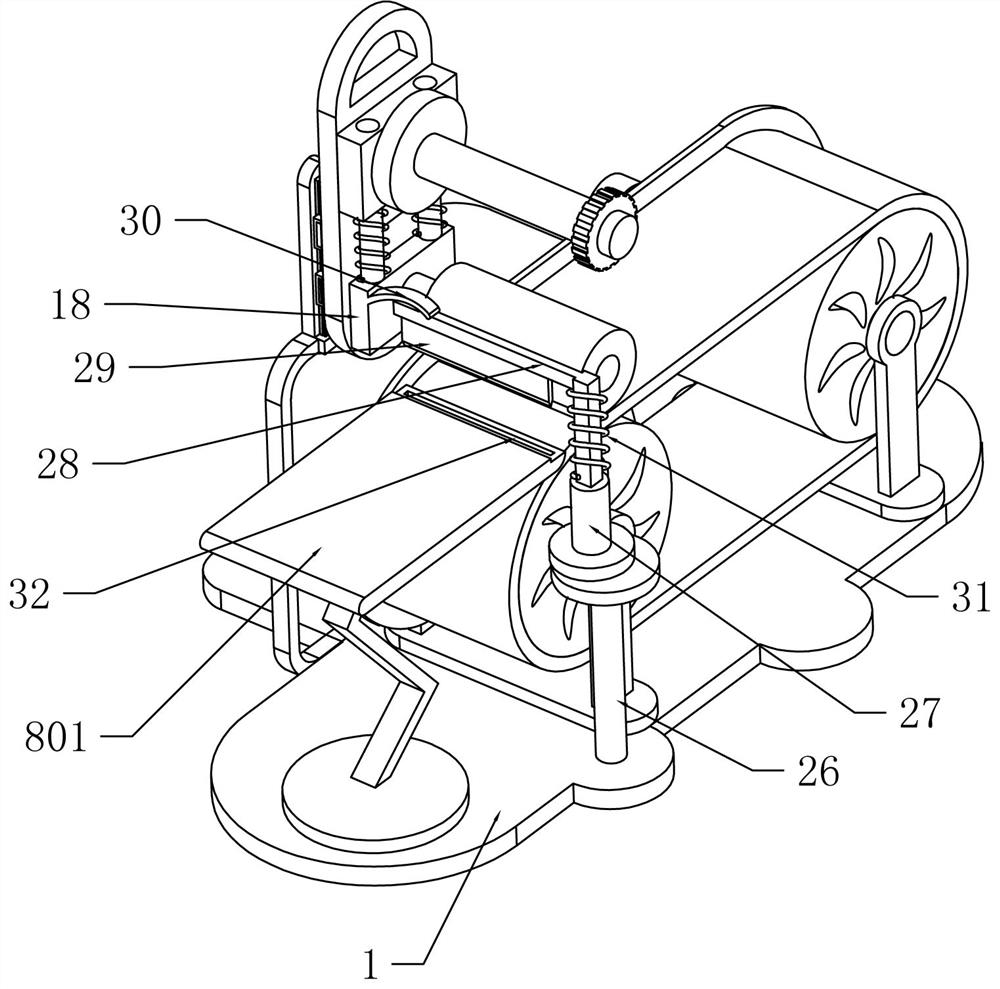

[0076] On the basis of Example 2, such as Figure 4-5 As shown, it also includes a stop rod 21, a rotating rod 22, a helical gear 23, a connecting rod 24 and a tightening nut 25. The stop rod 21 is affixed to the upper rear side of the base plate 1, and the rotation rod 22 is rotatably connected to the stop rod 21 upper part, the helical gear 23 is two groups, one of the first group of helical gears 23 is fixed on the upper end of the rotating rod 22, one of the second group of helical gears 23 is fixed on the lower end of the rotating rod 22, and the other helical gear 23 of the second group is fixed on the lower end of the rotating rod 22. The gear 23 is fixedly connected to the rear side of the left rotating shaft 6, the connecting rod 24 is connected to the sliding sleeve plate 17 in rotation, another helical gear 23 of the first group is fixedly connected to the rear end of the connecting rod 24, and the nut 25 and the connecting rod 24 are tightened before external threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com