Viscous material bin bottom discharger based on three-dimensional shearing effect

A material bin and unloader technology, applied in containers, large containers, packaging, etc., can solve problems such as difficulty in falling materials normally, sticking and blocking of sticky and immobile materials, difficulty in unloading, etc., and achieve the effect of increasing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

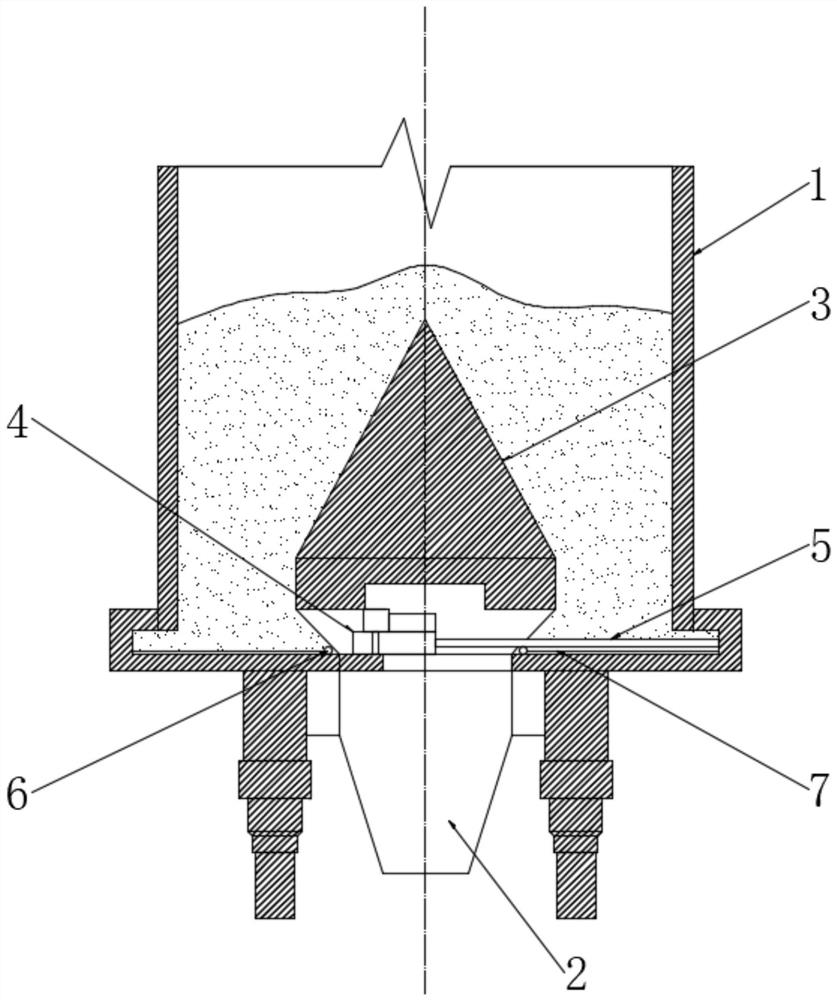

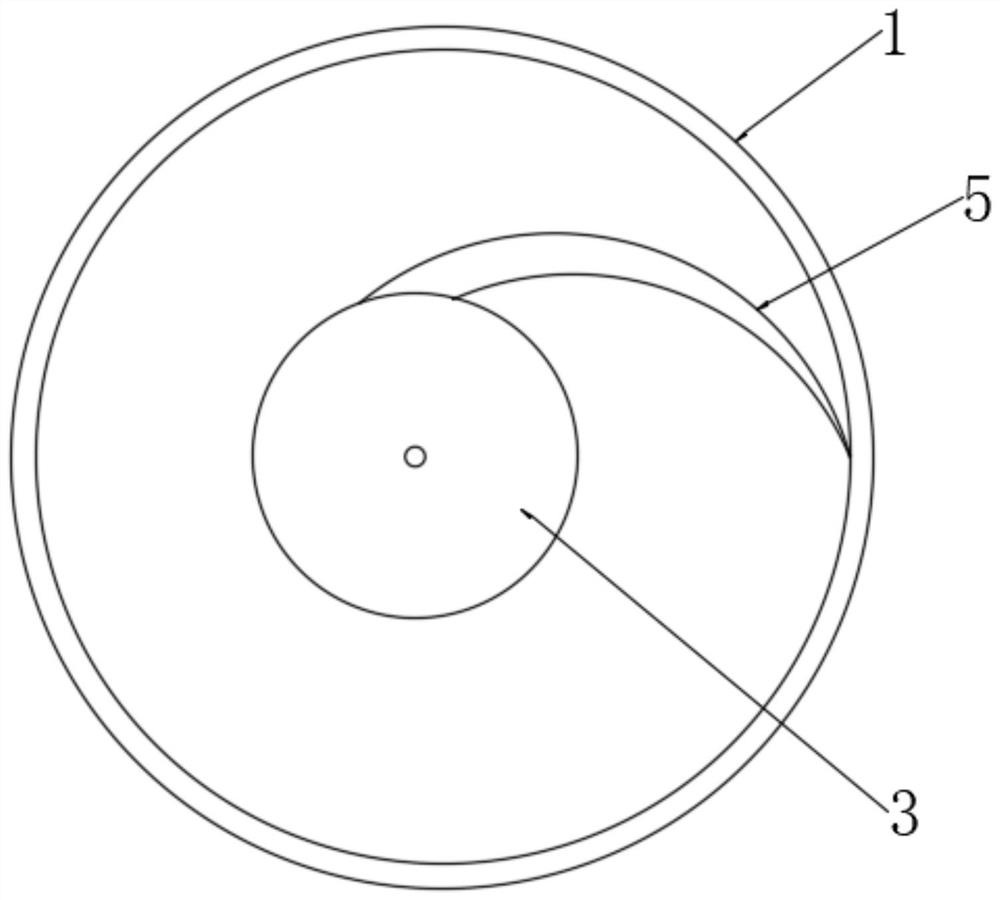

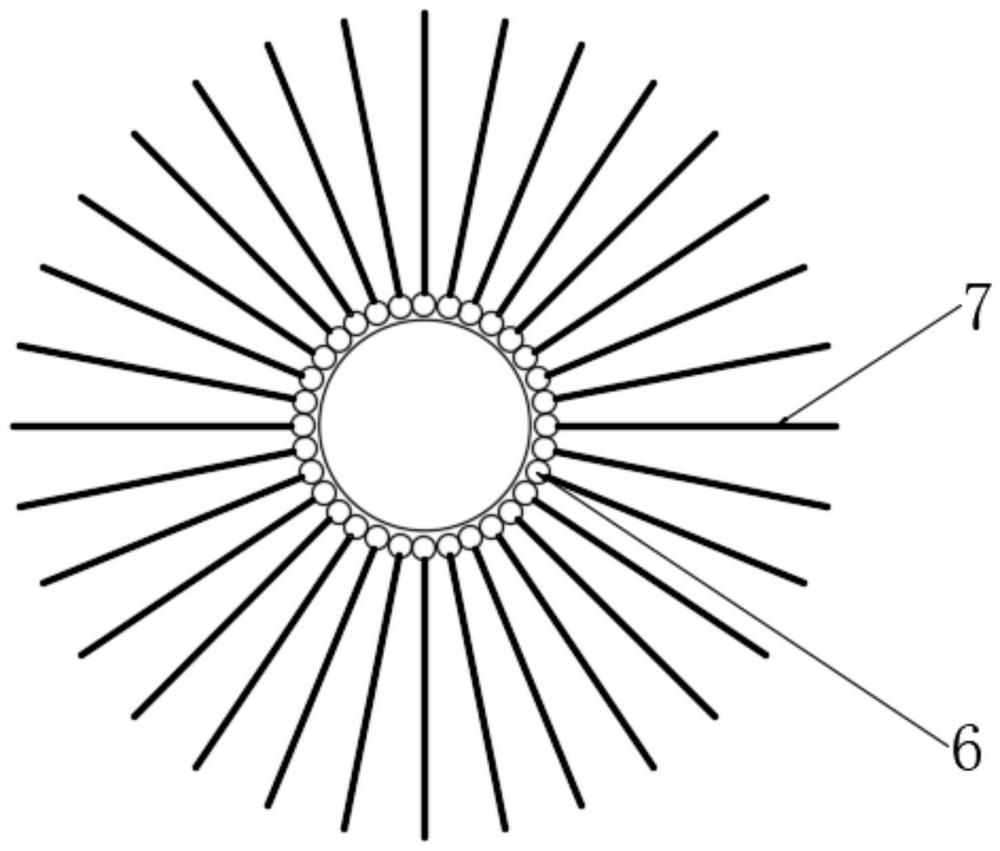

[0038] see Figure 1-3 , a viscous material bin bottom unloader based on three-dimensional shearing, including a bin 1, a central discharge port 2 is fixedly installed at the lower end of the bin 1, a decompression cone 3 is arranged on the upper side of the central discharge port 2, and a center The connection drive box 4 is fixedly connected between the discharge port 2 and the decompression cone 3, and is driven by a PF15-15-4P parallel shaft helical gear reducer. The curved discharge arm 5 is used for rotary shearing under the material. The logarithmic curve discharge arm 5 is in the shape of a logarithmic curve, and the logarithmic curve discharge arm 5 is tangent to the inner wall of the silo 1 away from the end connected to the drive box 4. , through the rotation and shearing of the logarithmic curve discharge arm and the material, the material moves to the central discharge port and is discharged. Due to the rotary shear discharge, the material layer is in an overall d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com