3D protective film capable of being subjected to heat setting or UV irradiation setting

A protective film and heat setting technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve complex problems, reduce unlocking sensitivity, cumbersome production process, etc., achieve streamlining and optimization, improve process yield and production Efficiency, guaranteed sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

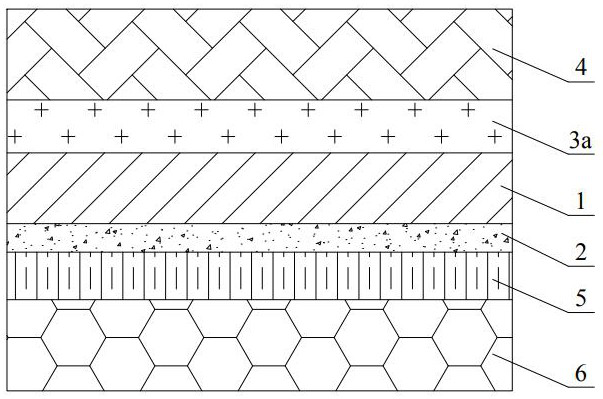

[0027] Such as figure 1 As shown, the 3D protective film that can be heat-set or UV-irradiated and set includes a protective film body. The protective film body includes an optical film substrate 1. The lower surface of the optical film substrate 1 is coated with a base film layer 2. The base film layer The shrinkage rate of 2 is higher than that of the optical film substrate 1. The optical film substrate 1 is a TPU or PMMA film that is cast or coated, and the base film layer 2 is coated on the surface of the optical film substrate 1 and passed through UV. Cured or thermally cured TPU or acrylic material, the upper surface of the optical film substrate 1 is coated with a layer of self-repairing coating 3a, and a layer of PET protective film 4 is compounded on the self-repairing coating 3a, and the lower surface of the base film layer 2 is coated with Covered with a layer of exhaust adhesive layer 5, the lower surface of the exhaust adhesive layer 5 is compounded with a layer o...

Embodiment 2

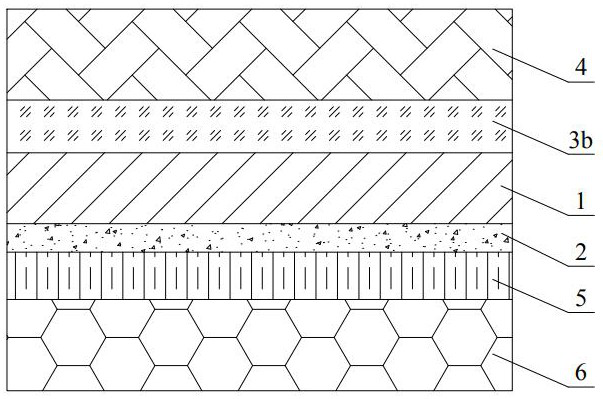

[0038] like figure 2 As shown, the difference between this embodiment and embodiment 1 is that the structure of the self-healing coating 3a is replaced by the structure of the hardened anti-scratch layer 3b, that is, the structure between the optical film substrate 1 and the PET protective film 4 is a hardened anti-scratch layer. Scratch coat 3b, wherein the hardened scratch-resistant layer 3b has a thickness of 1-5um, a water drop angle ≥ 108°, and a dynamic friction coefficient u ≤ 0.1. The 3D protective film of this structure can tear off the PET release film 6 and the PET protective film 4 Afterwards, it is pasted on the screen of the mobile phone. The top hardened scratch-resistant coating 3b can have good anti-fingerprint and scratch-resistant effects. The specific material can be selected from common hardened scratch-resistant coatings on the market. In this embodiment , the wear resistance of the hardened scratch-resistant coating 3b formed by coating can meet ≥2500 t...

Embodiment 3

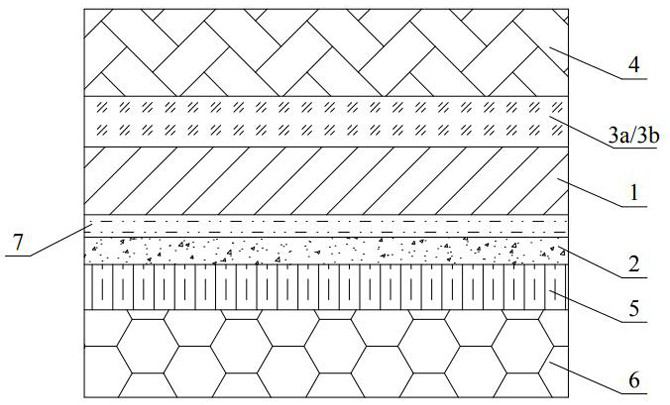

[0044] The difference between this embodiment and embodiment 1 or embodiment 2 is that the anti-blue light structure is added, which specifically includes the following three types of structures: 1. image 3 As shown, the protective film body also includes a layer of anti-blue light layer 7, which is located between the optical film substrate 1 and the base film layer 2; two, as Figure 4 As shown, the protective film body also includes a layer of anti-blue light layer 7, and the anti-blue light layer 7 is located between the base film layer 2 and the exhaust adhesive layer 5; 3. The anti-blue light layer is not added separately, but is placed in the protective film body A blue light absorber is added in any layer of the structure. The above-mentioned blue light absorber can be selected from existing blue light absorbers on the market, and the present application does not specifically limit it, and the specific structure of the anti-blue light layer 7 can also be a separate co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com