Mechanism for introducing utility line into vacuum chamber, film-forming apparatus and film-forming system

A technology of a vacuum chamber and a film-forming device, applied in the field of mechanism, can solve the problems of reduced vacuum sealing performance of a connecting part and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] (Basic structure of film forming equipment)

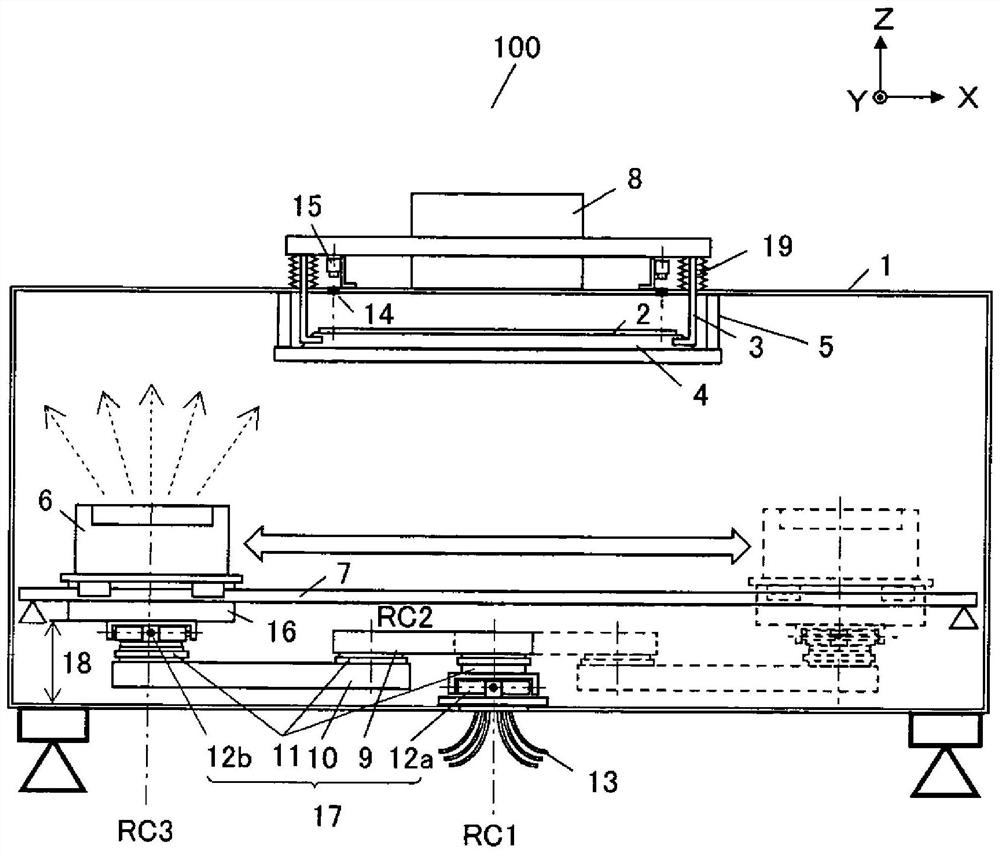

[0036] figure 1 It is a schematic cross-sectional view showing the overall structure of the film forming apparatus 100 according to the first embodiment. exist figure 1 The X-axis, Y-axis, and Z-axis shown in the figure are a three-axis orthogonal coordinate system. The horizontal plane is defined by the X-axis and the Y-axis, and the direction opposite to the direction of gravity is defined by the Z-axis. However, in implementing the present invention, it is not necessary for the X-axis, Y-axis, and Z-axis to be a three-axis orthogonal coordinate system, and it is not necessary for the X-axis and the Y-axis to define a horizontal plane and the Z-axis to define a direction opposite to the direction of gravity. When the X-axis is the first axis, the Y-axis is the second axis, and the Z-axis is the third axis, it is only necessary that the first, second, and third axes intersect each other. In addition, in the following des...

Embodiment approach 2

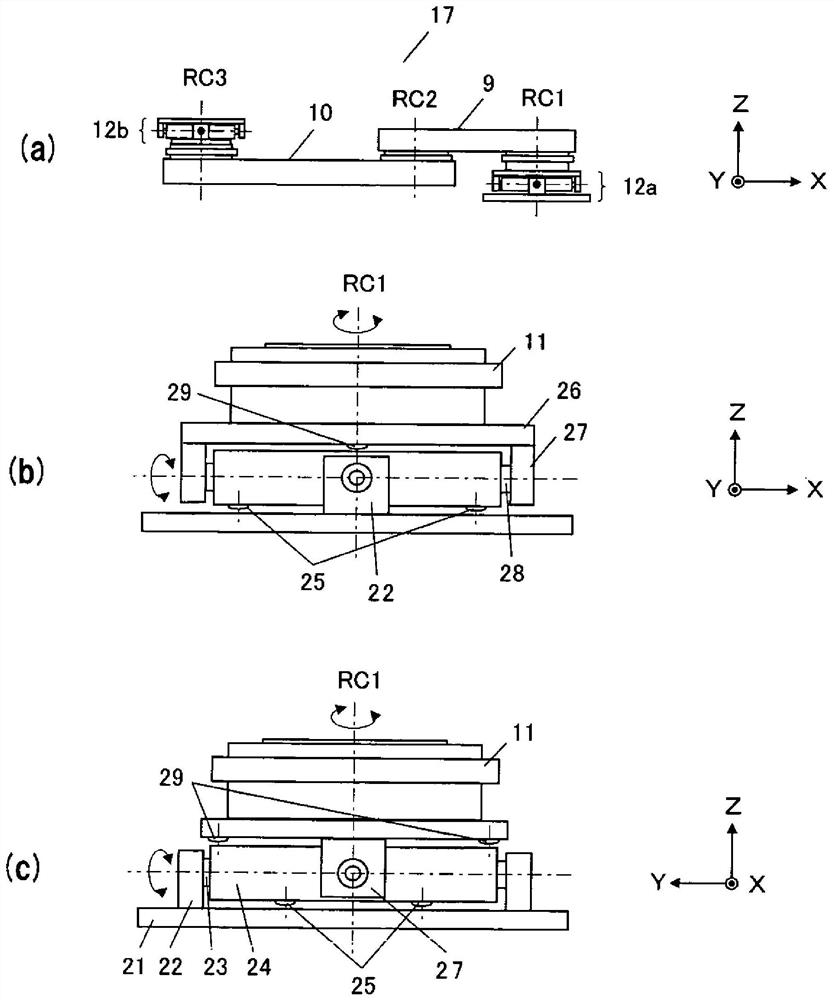

[0071] In Embodiment 1, a gimbal mechanism is provided on the first turning part and the third turning part, and the gimbal mechanism includes a swinging X-axis and A swing Y-axis 23 for supporting swingably about an axis parallel to the Y-axis.

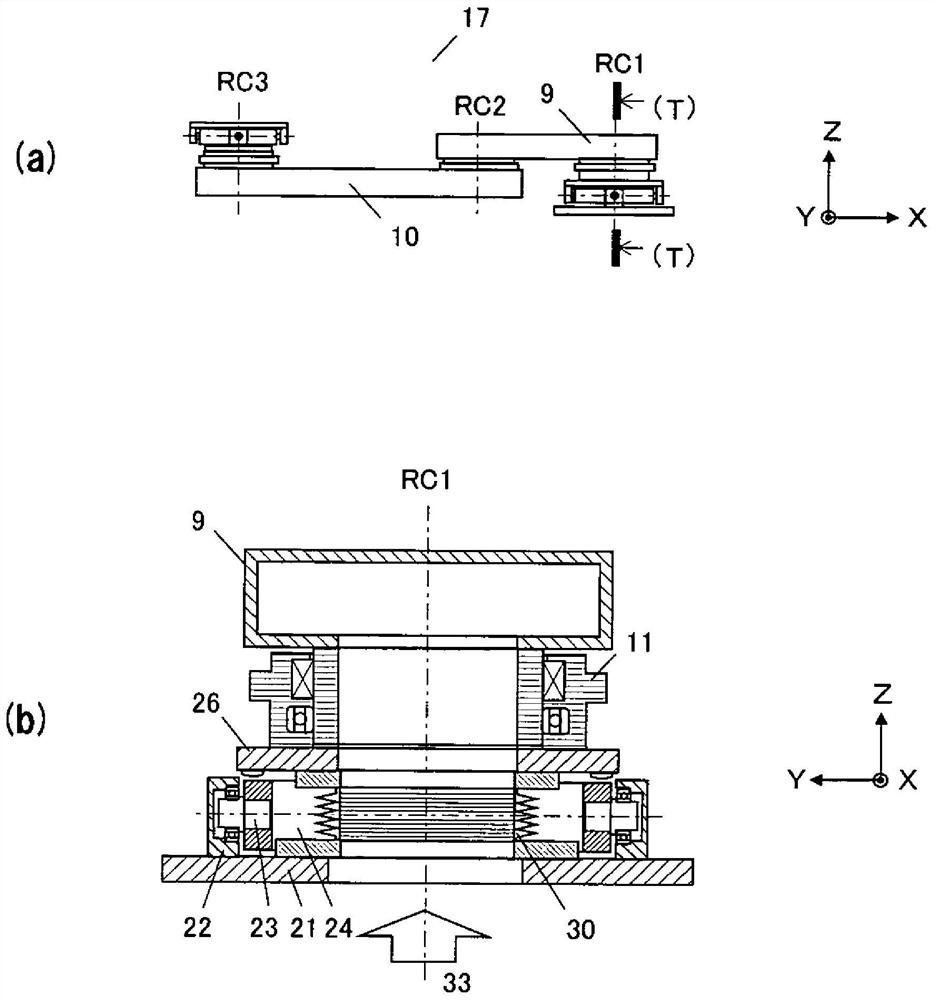

[0072] On the other hand, in Embodiment 2, instead of the gimbal mechanism, a magnetic fluid bearing having a rotation connecting portion capable of relative spherical motion is disposed on the first rotating portion and the third rotating portion. That is, in the device described in Japanese Patent Application Laid-Open No. 2015-121265 , the magnetic fluid bearing capable of spherical motion arranged on the second rotating part is disposed on the first rotating part and the third rotating part. The magnetic fluid bearing capable of spherical motion may be arranged only on the first rotating portion and the third rotating portion, or may be further arranged on the second rotating portion. Hereinafter, descriptions of matters common ...

Embodiment approach 3

[0076] The film-forming apparatuses of Embodiments 1 and 2 are film-forming apparatuses that support the substrate so that the main surface of the substrate is horizontal, and move the vapor deposition source in the horizontal in-plane direction. In contrast, in the film formation apparatus of Embodiment 3, the substrate is supported so that the principal surface of the substrate is oriented along the vertical direction during vapor deposition, and the vapor deposition source is vertically positioned along the principal surface of the substrate. The film-forming device moves in the direction. Descriptions of parts common to Embodiment 1 are omitted.

[0077] Image 6 It is a schematic sectional view showing the film formation apparatus 100 of this embodiment. It should be noted that the same reference numerals as in Embodiment 1 are attached to members having the same functions as in Embodiment 1, but the positions and orientations where the members are provided are not nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com