A multi-tooth banana stem fiber extraction machine with scraping belt

A technology of fiber extraction machine and banana stalk, which is applied in the direction of fiber mechanical separation, fiber treatment, mechanical treatment, etc., and can solve the problems of thick banana stalk, low mechanical operation efficiency, and large fiber loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

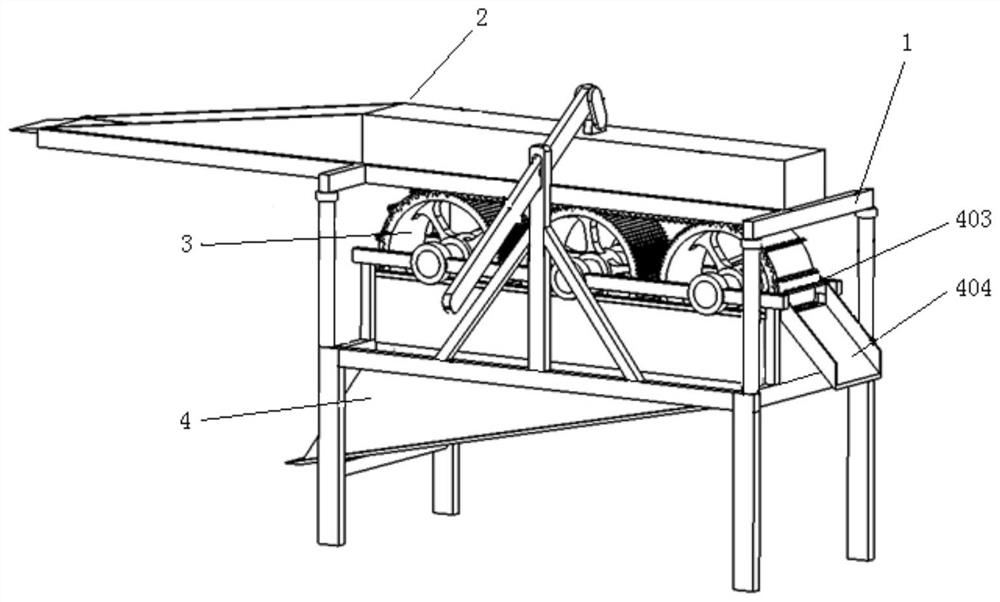

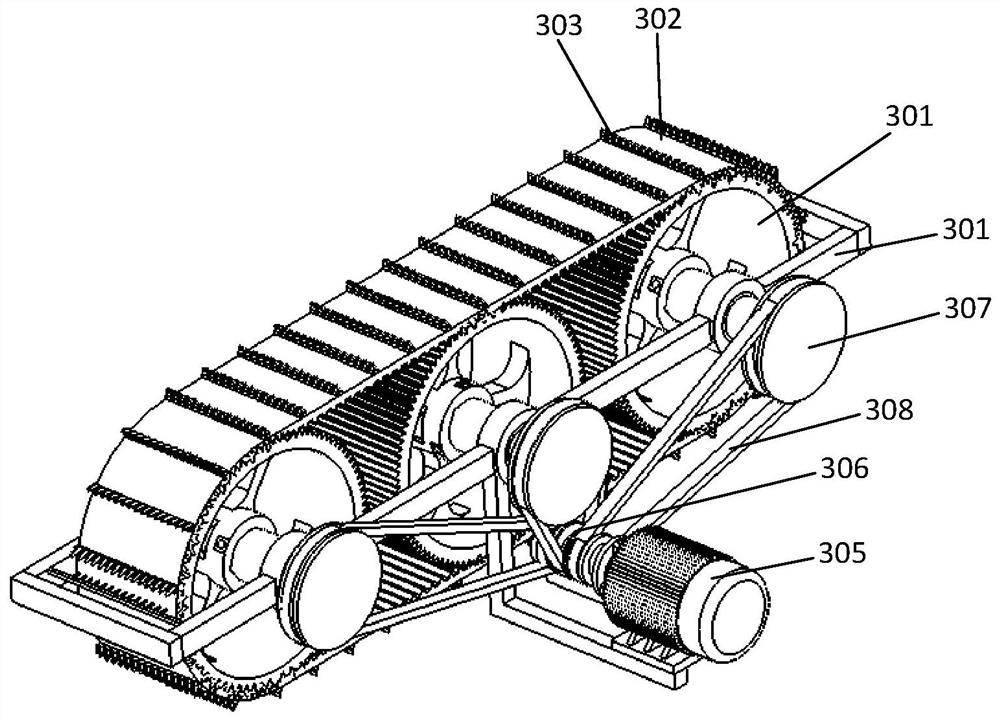

[0033] A scraper belt multi-tooth banana stem fiber extraction machine described in this embodiment is shown in Figure 1 to Figure 7 shown.

[0034] like figure 1 As shown, a scraping belt multi-tooth banana stalk fiber extraction machine described in this embodiment is composed of a frame 1, a feeding device 2, a fiber scraping device 3 and a discharge device 4; the feeding device 2, The fiber scraping device 3 and the discharge device 4 are installed on the frame 1 in sequence from top to bottom.

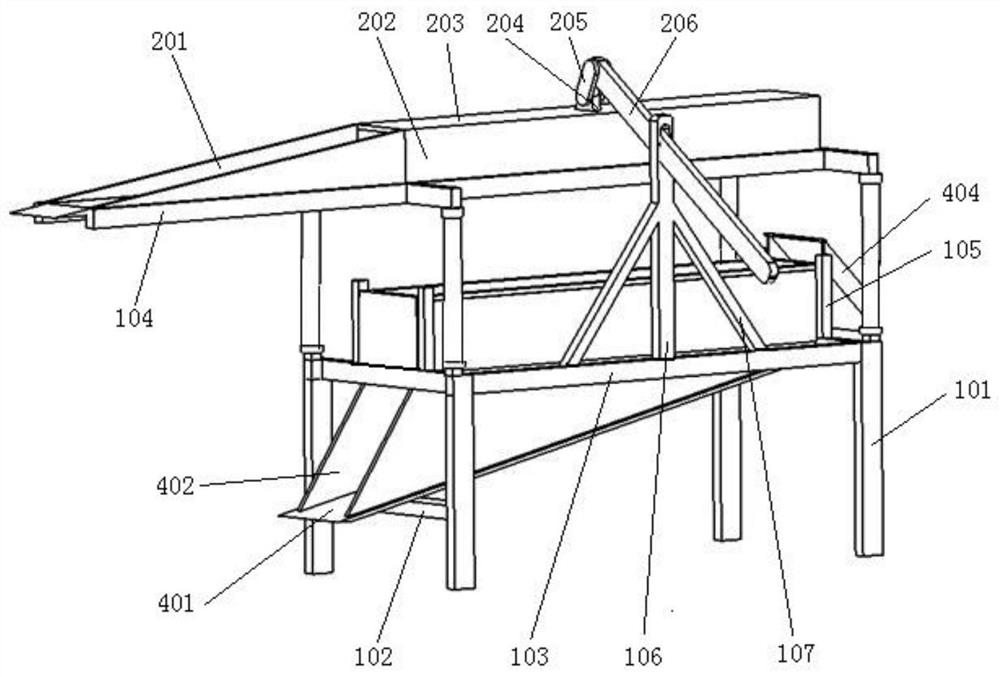

[0035] like figure 2 As shown, the frame 1 is composed of four columns 101, five short beams 102, five long longitudinal beams 103, two suspension beams 104, four short columns 105, a lever column 106 and two oblique struts 107. ; On the two columns 101 on the left side of the frame 1 (that is, the side of the feeding and discharging chute), three short crossbeams 102 are respectively fixed between the two columns 101 according to the upper, middle and lower positions, on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com