Abandoned mine shaft gas leakage prevention and control method

A gas leakage and wellbore technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult gas leakage locations, fewer users, gas leakage, etc., to avoid resource waste and environmental pollution, and improve economic benefits , Guarantee the effect of extraction and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

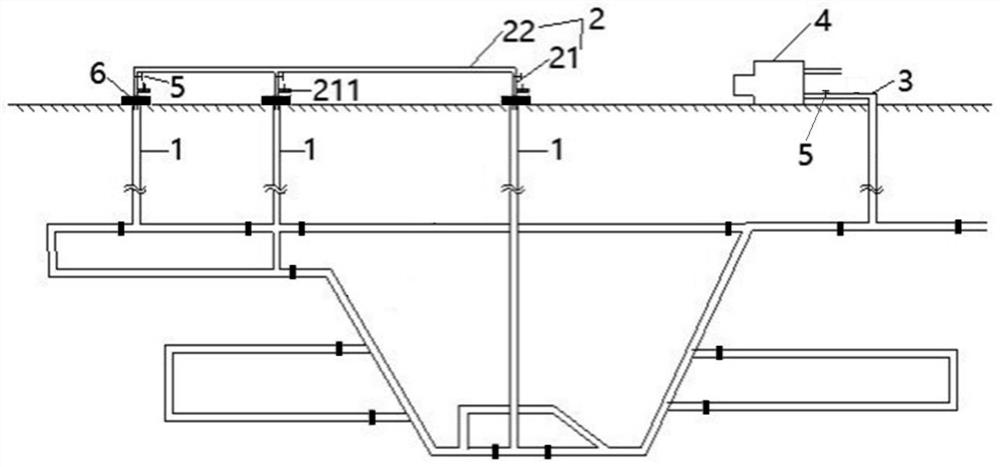

[0027] Such as figure 1 As shown, this embodiment discloses a method for preventing and controlling gas leakage in an abandoned mine shaft, comprising the following steps:

[0028] Step 1: Observe the gas pressure difference and concentration in multiple wellbores 1, and check the gas leakage of the wellbore 1 to determine the gas leaking wellbore 1;

[0029] Step 2: when the differential pressure of one or more of the well bores 1 is positive and the sum of the differential pressures of all the well bores 1 is negative, that is, the overall air intake; all the well bores 1 are passed through the connecting pipeline 2 are connected together in parallel, and are regulated by the valve 5 arranged on the communication pipeline 2 to control the pressure difference of all the well bores 1 to be negative.

[0030] There are three shafts 1, the outlet end is arranged on the ground, and the other end is arranged underground.

[0031] The communication pipeline 2 includes an exhaust ...

Embodiment 2

[0037] Such as figure 1 As shown, this embodiment discloses a method for preventing and controlling gas leakage in an abandoned mine shaft, comprising the following steps:

[0038] Step 1: Observe the gas pressure difference and concentration in multiple wellbores 1, and check the gas leakage of the wellbore 1 to determine the gas leaking wellbore 1;

[0039] Step 2: When the differential pressure of one or more of the well bores 1 is positive and the sum of the differential pressures of all the well bores 1 is positive, the gas will be released as a whole; connect all the well bores 1 through the connecting pipeline 2 connected in parallel, the drainage equipment 4 is turned on to drain the wellbore 1, and the pressure difference sum of all the wellbores 1 is controlled to be a negative value.

[0040] There are three shafts 1, the outlet end is set on the ground, and the other end is set under the ground.

[0041] The communication pipeline 2 includes an exhaust pipe 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com