Air-tight seal structure for driven tool holder

A power tool holder, air sealing technology, applied in the direction of the engine seal, engine components, large fixed members, etc., can solve the problems of reducing the service life of the sealing ring, grease failure, product damage, etc., to prevent leakage and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

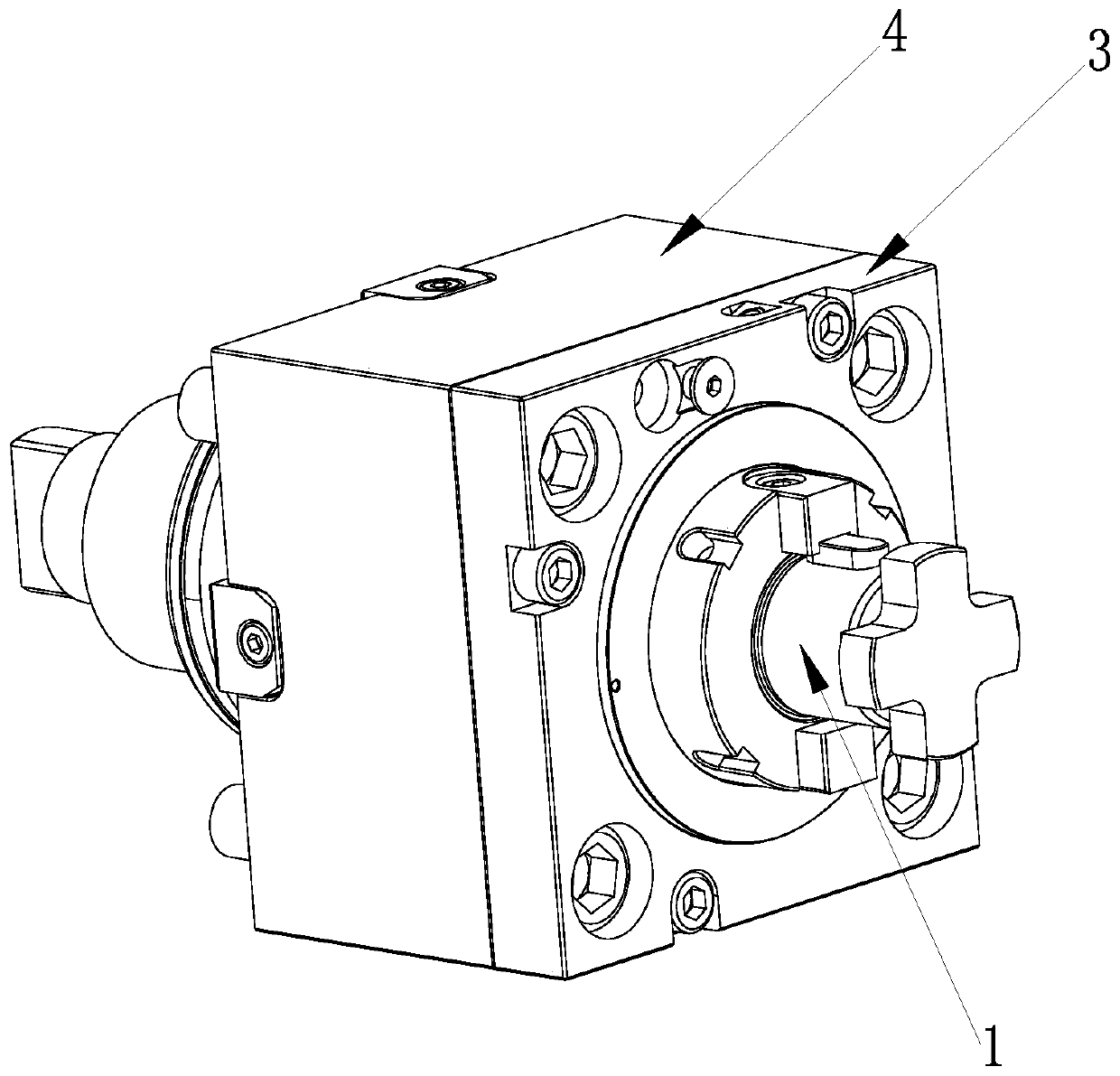

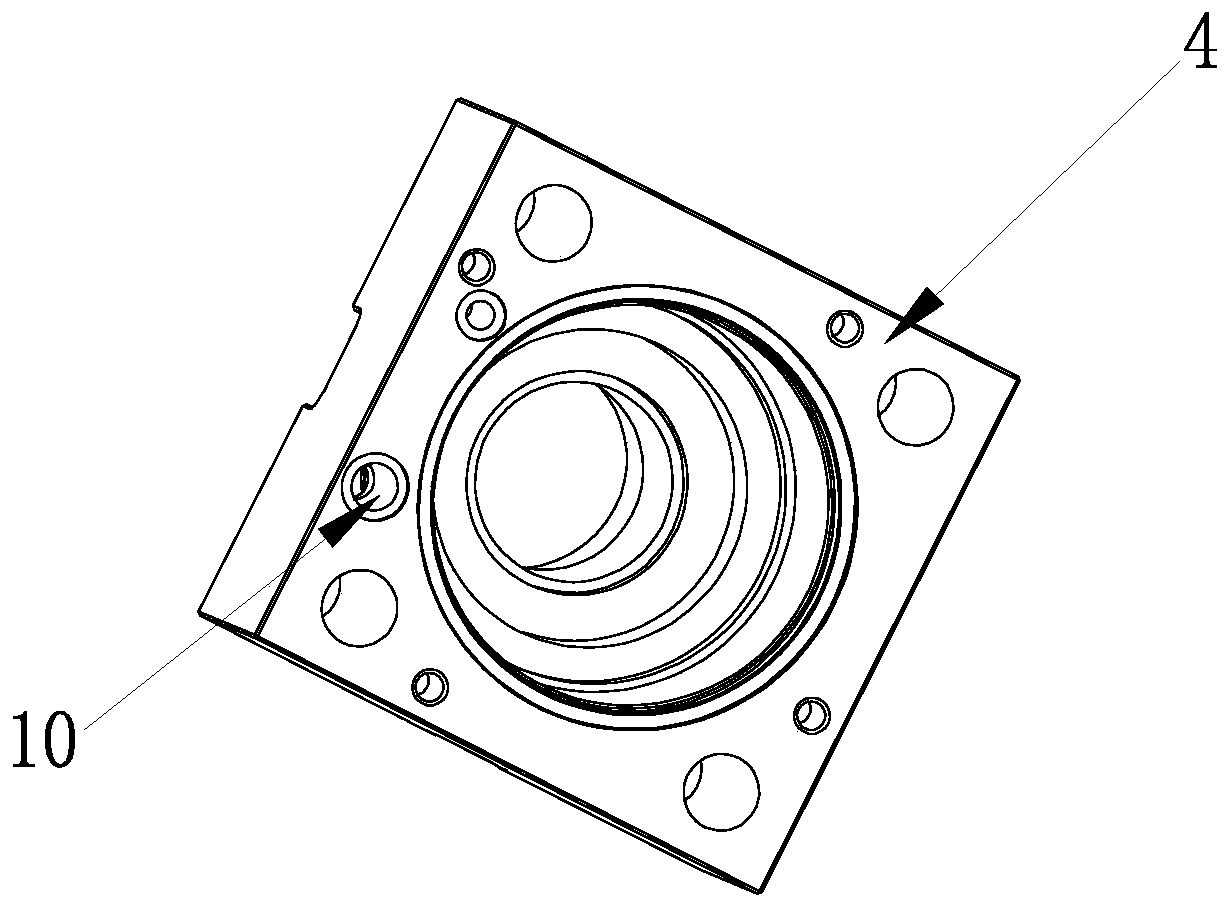

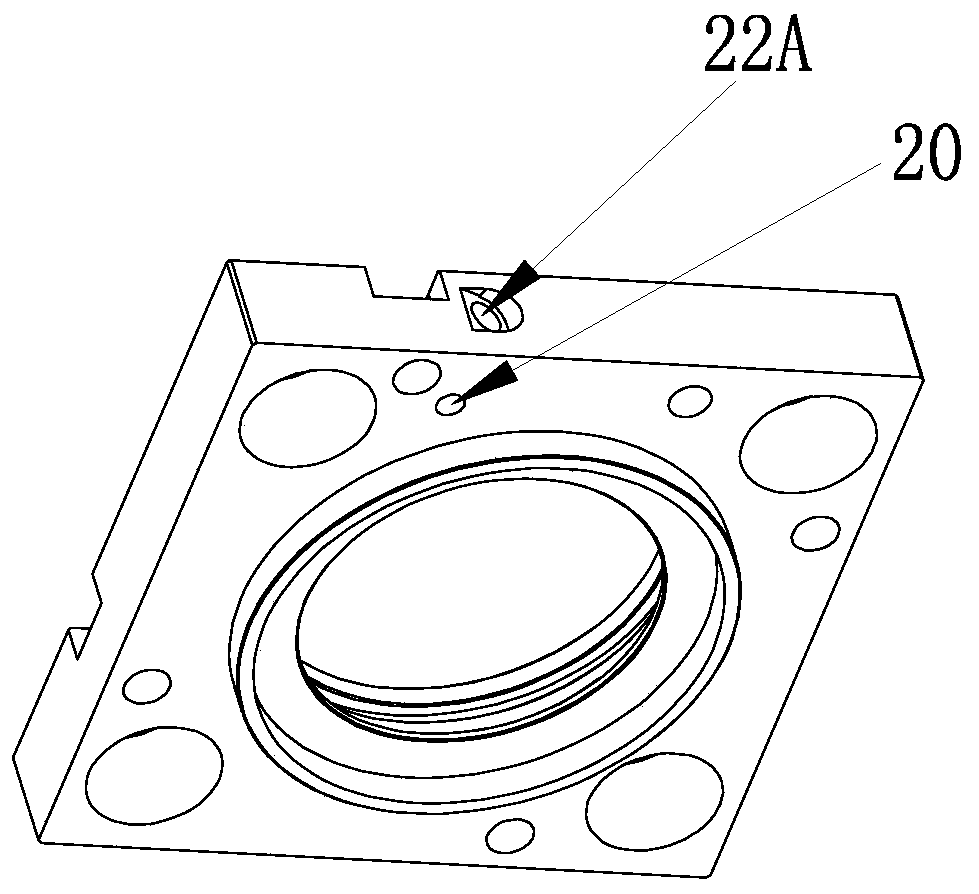

[0030] Such as Figure 1-7 As shown, the present embodiment provides a kind of airtight structure for the power tool holder, including the tool holder box 4, the flange 3 fixed on the tool holder box 4; the right end surface of the tool holder box 4 and the The machine tool is fixed, the front end of the flange 3 is installed with a waterproof disk 2, and the waterproof disk 2 is sleeved on the main shaft 1; the inner end surface on the left side of the flange disk 3 is in contact with the right end surface of the waterproof disk 2, and the inner hole at the left end of the flange disk 3 is in contact with the waterproof The outer circle of the disc 2 is socketed, and the inner hole on the right side of the waterproof disc 2 and the outer circle of the main shaft 1 keep a small gap, and the inner end surface of the waterproof disc 2 and the end face of the main shaft 1 maintain a pin gap, and the inner hole on the left side of the waterproof disc 2 and the main shaft 1 keep a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com