Stepless speed change belt glue sleeve and manufacturing method thereof

A technology of stepless speed change and manufacturing method, which is applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc., can solve problems such as long time, high cost, and low market competitiveness, so as to improve production efficiency, reduce production time, The effect of solving the time problem of the bottleneck station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

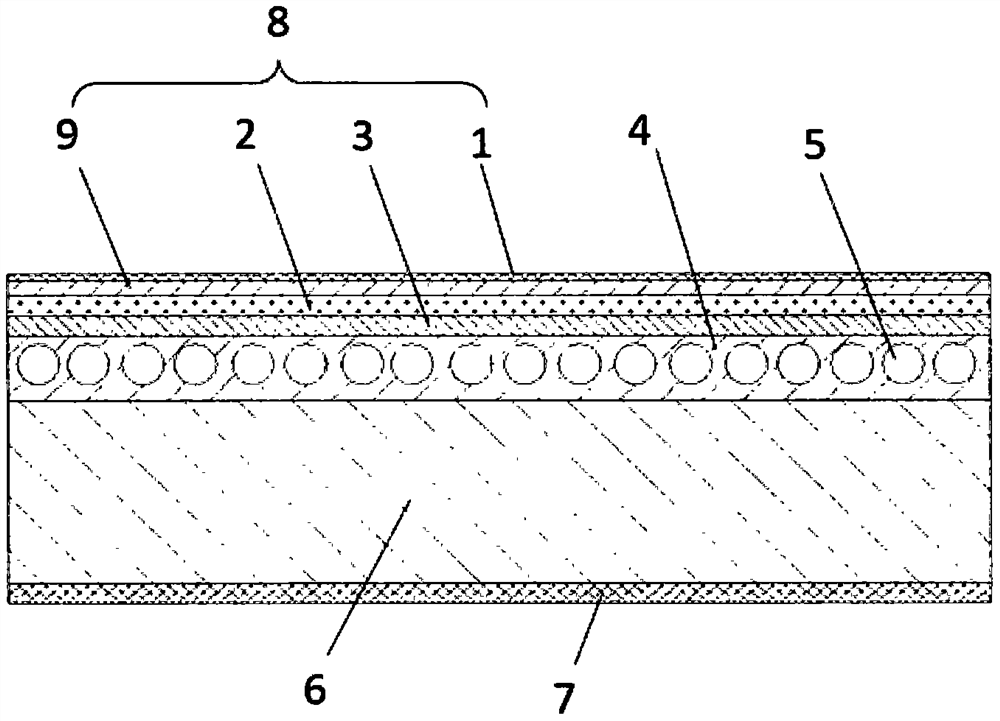

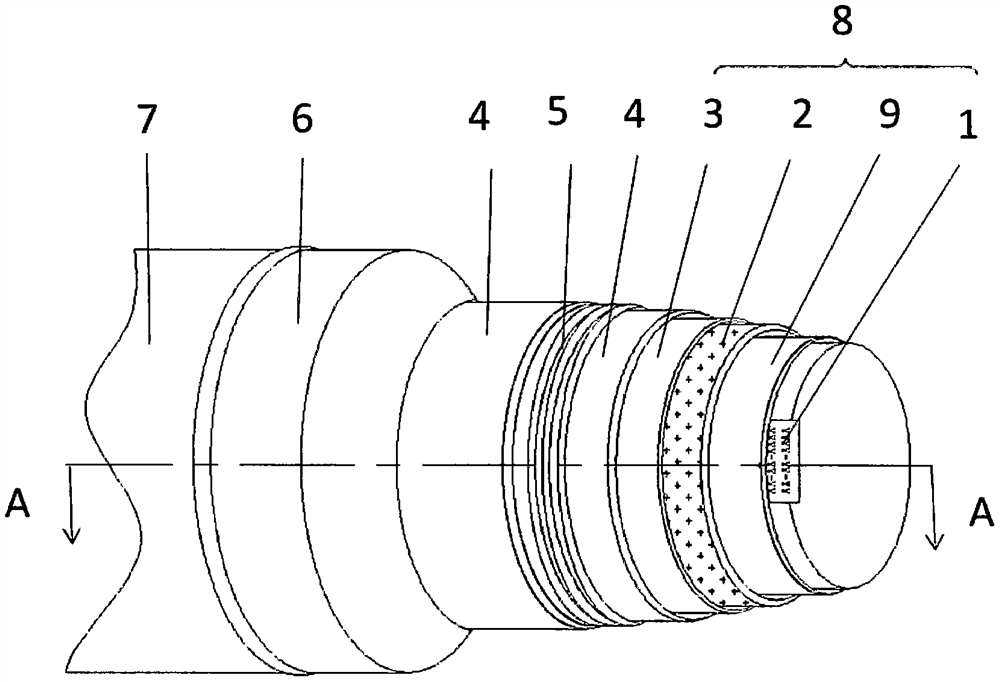

[0032] figure 1 It is a schematic diagram of the vulcanized rubber sleeve 10 with label information after vulcanization, figure 2 A cross-sectional view of an unvulcanized sleeve. The rubber sleeve of the continuously variable transmission belt sequentially includes a label layer 1 with a certain width and can run through the entire length of the rubber sleeve. The label layer 1 has production information, such as production date, trademark information, etc., and the side of the label layer 1 with information is close to On the outer side of the outer adhesive layer 9, the label information will be transferred to the outer side of the outer adhesive layer 9 after the rubber sleeve is vulcanized, and then the label layer 1 is torn off, leaving only the label information on the outer side of the outer adhesive layer 9. The top fabric layer 2 that is close to the inner side of the outer adhesive layer 9 (the side opposite to the label layer 1), and the inner rubber layer 3 (now...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com