Spinning oven

An oven and textile technology, applied in the textile field, can solve the problems of long working hours and high labor intensity, and achieve the effects of high drying efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

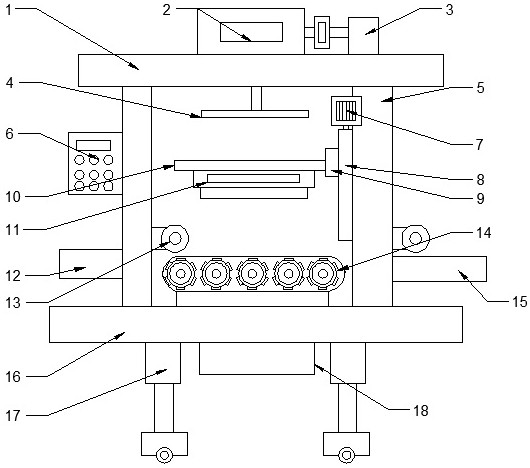

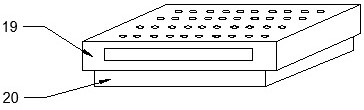

[0019] see Figure 1~3 , in an embodiment of the present invention, a textile oven includes a housing 5; a top base 1 is installed on the top of the housing 5; a driving box 2 is installed on the top of the top base 1; the driving box 2 communicates with the Cooler 3; fan blades 4 are installed on the bottom of the top base 1; a control panel 6 and a feed port 12 are installed on one side of the housing 5; the other side of the housing 5 is provided with a discharge Port 15; the inside of the housing 5 is equipped with a stamping mechanism; the housing 5 is installed on the top of the base 16; the top of the base 16 is provided with a drying mechanism 14; the bottom of the base 16 is equipped with a mobile agency17.

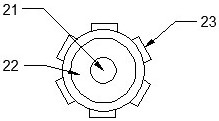

[0020] Further, the stamping mechanism includes a driving mechanism 7; the driving mechanism 7 includes a stepping motor; the stepping motor is connected to a reversing mechanism through a coupling; the reversing mechanism is connected to a gear through a coupli...

Embodiment 2

[0025] see figure 1 , the top seat 1 is provided with guide rollers 13 corresponding to the feed inlet 12 and the discharge outlet 15; through the arrangement of the guide rollers 13, the order of the entry and exit of textiles is maintained.

[0026] The working principle of the present invention is: through the setting of the driving mechanism 7, the slide rail 8, the slider 9, the sliding rod 10 and the pressure device 11, the textile is compressed to remove a part of the moisture inside the textile; through the setting of the drying mechanism 14, Textiles can be dried; the steam cold area can be recovered through the fan blade 4, the driving box 2 and the cooler 3; the water squeezed by the presser 11 can be collected through the water storage tank 18; the setting of the guide roller 13 can keep the textile from entering and out in order. In summary, the present invention is convenient to use and has high drying efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com