A system and method for monitoring the amount of broken stones in the riprap pipe of an underwater leveling machine

A technology of monitoring system and riprap tube, which is applied in the direction of mechanical equipment, measuring devices, engine components, etc., can solve the problems affecting the monitoring accuracy and work efficiency, turbid water, low visibility, etc., and achieve the improvement of leveling operation efficiency and results Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

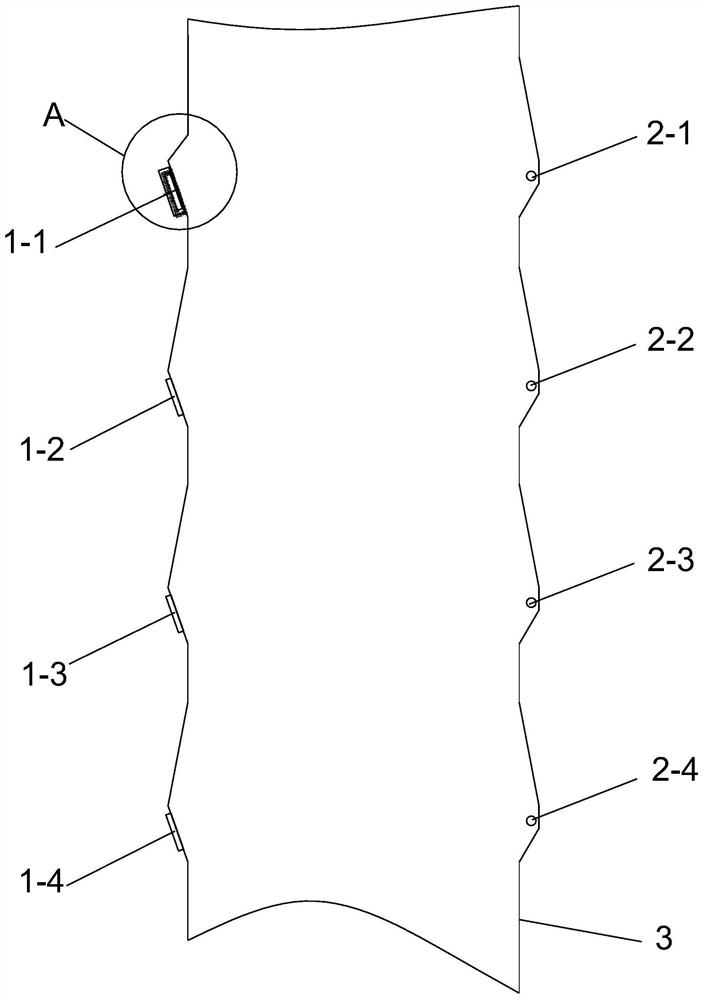

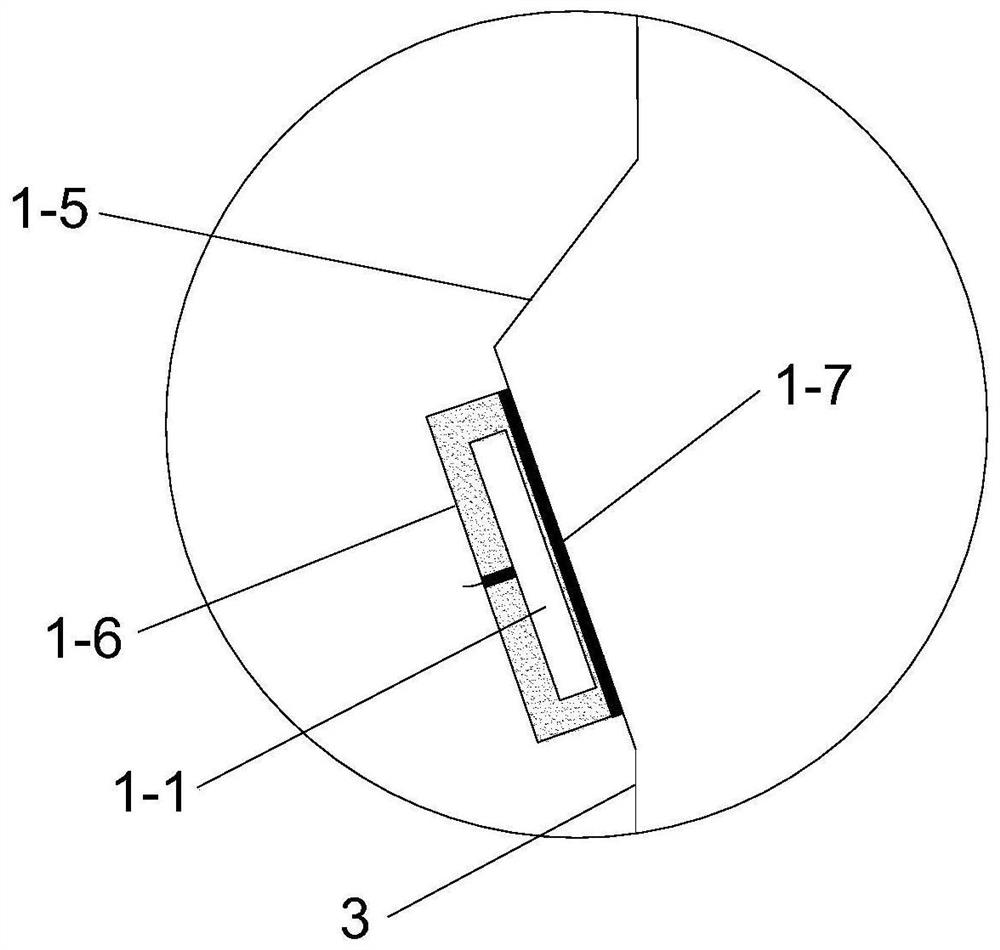

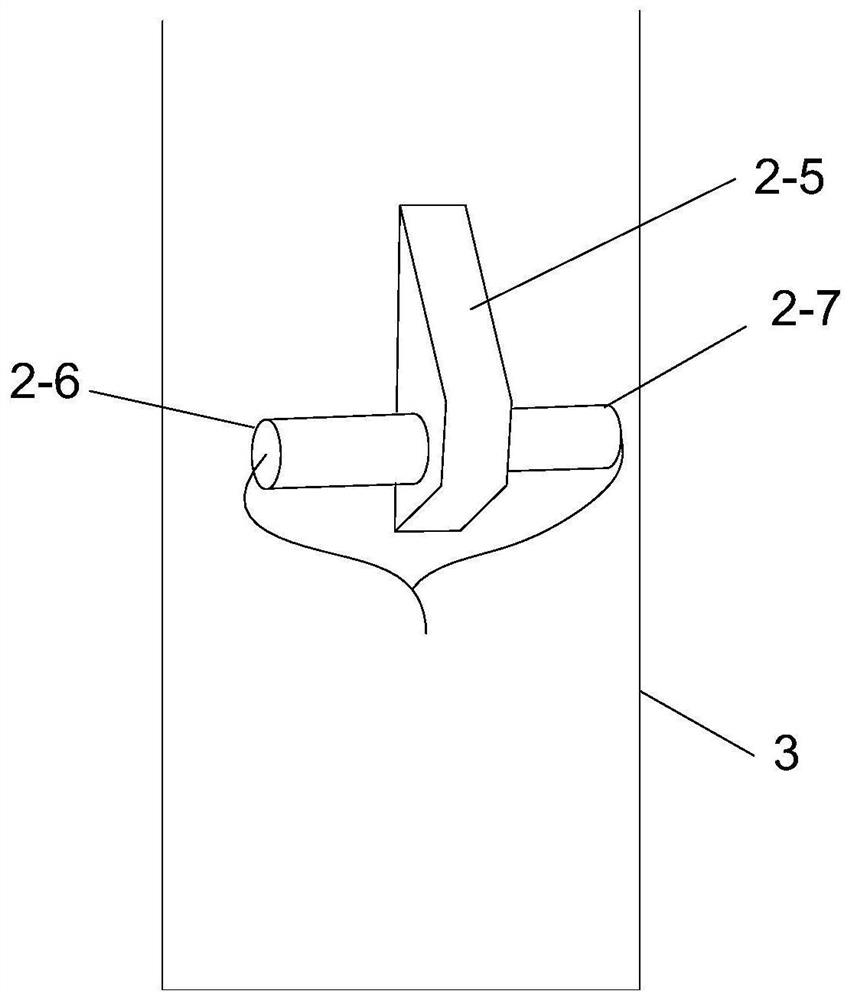

[0022] A system for monitoring the amount of crushed stone in a riprap tube of an underwater leveler, comprising a light sensor group, a pressure gauge group, a comprehensive acquisition instrument and a computer system, the light sensor group comprising at least two light sensors, one being a light sensor I2- 1. It is installed at the highest position of the designed crushed stone volume of the riprap tube 3, and the other is the light sensor II 2-4, which is installed at the lowest position of the designed crushed stone volume of the rippling tube 3. The light sensor I2-1 and all The light sensor II2-4 is located on the right side of the riprap tube 3, and the pressure gauge group includes at least two pressure gauges, one of which is a pressure gauge I1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com