Two-dimensional bar code laser marking method

A technology of laser marking and dimensional bar code, which can be applied in temperature recording method, digital marking record carrier, digital marking by photographing/thermal imaging, etc., which can solve the problems of reducing and wasting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

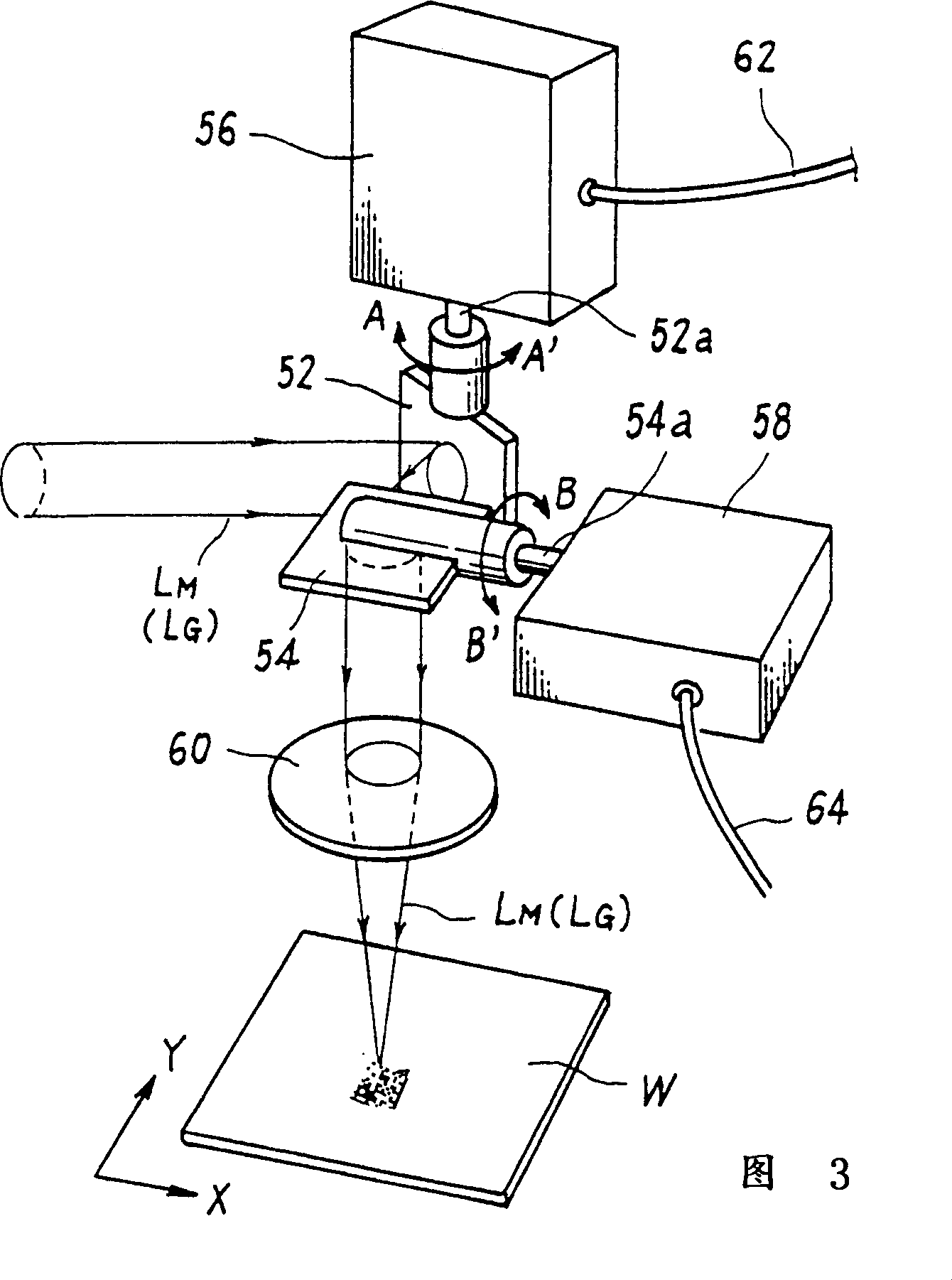

[0039] Below in conjunction with represented the preferred embodiment of the present invention Figure 1 to Figure 13 The invention is described.

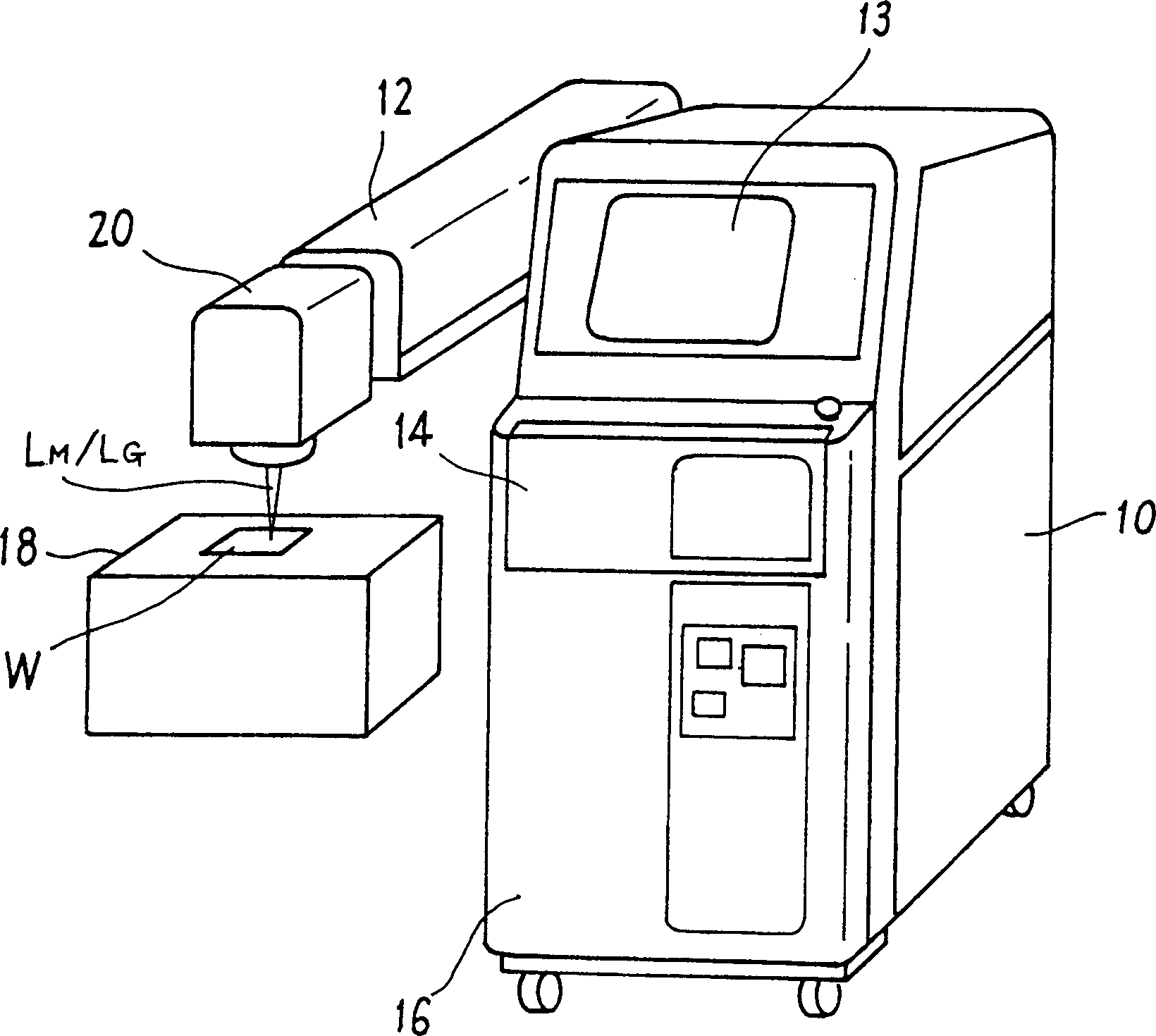

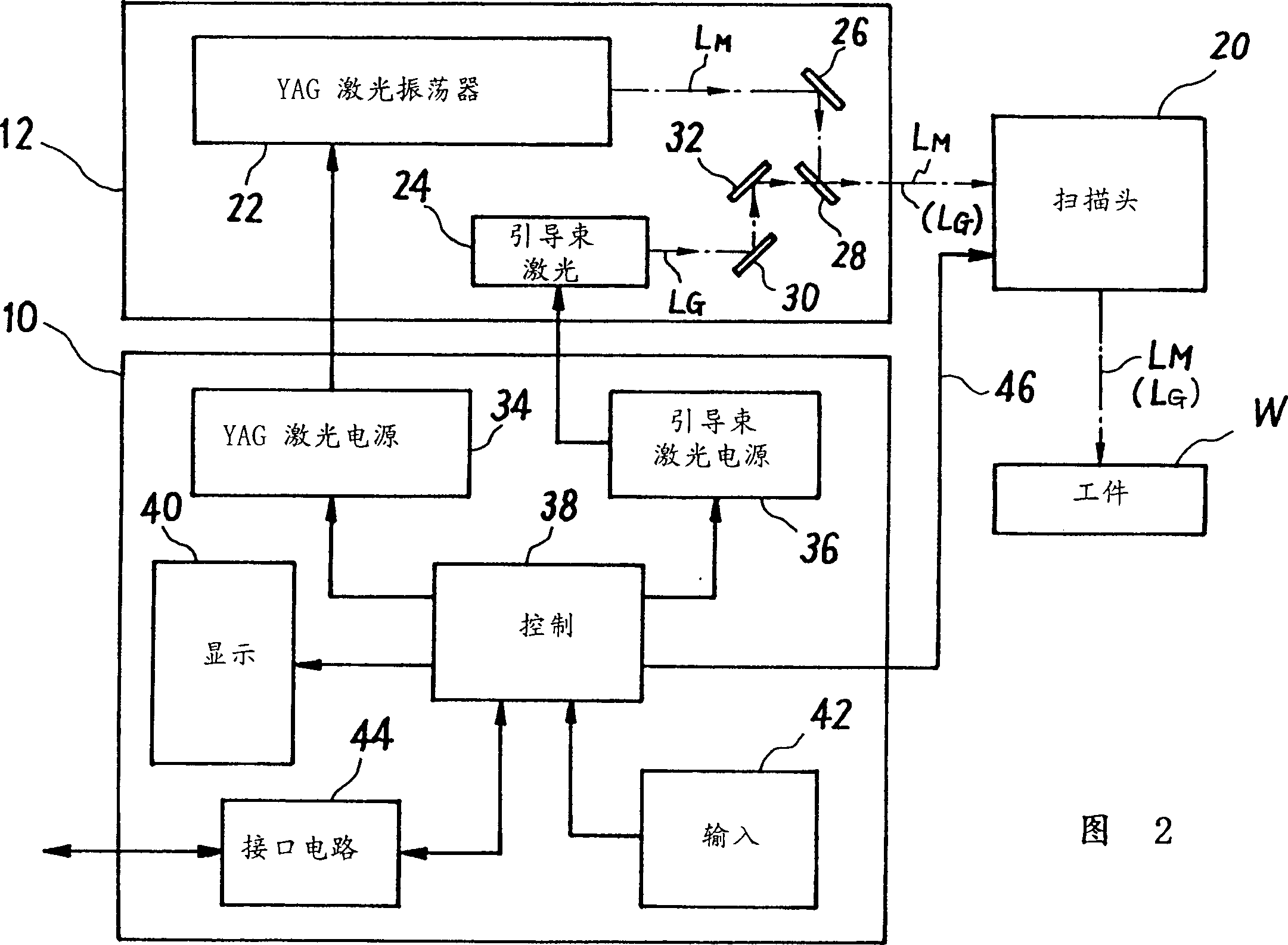

[0040] figure 1 A scanning type YAG (yttrium aluminum garnet) laser marking device used in a laser marking method according to an embodiment of the present invention is shown. The YAG laser marking device includes a control power supply unit 10 , a laser oscillation unit 12 and a scanning head 20 .

[0041] The control power supply unit 10 includes an upper member provided with a display 13 composed of a display unit, a middle member provided with a keyboard and a control panel (the back of the front door 14), and a laser power supply circuit, a laser cooling device, etc. etc. lower member (the back of the front door 16). The scan control signal is generated by the control unit within the intermediate member and transmitted to the scan head 20 through a predetermined signal line (not shown). The scanning head 20 is placed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com