Shockproof optical fiber connector convenient to maintain on site

A fiber optic connector, on-site maintenance technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of reduced optical signal transmission performance, interruption, increased maintenance costs and expenses, etc., to achieve broad market application prospects, reasonable structure design, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing of description, by describing embodiment, the present invention will be further described:

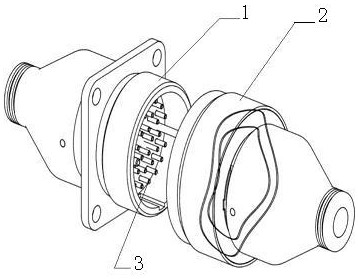

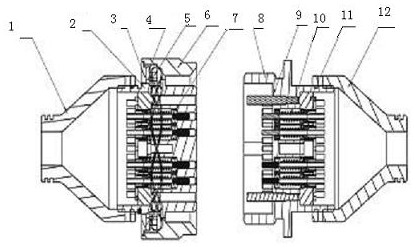

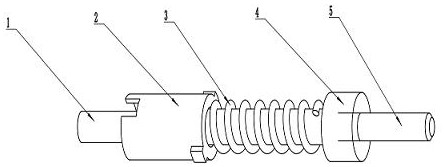

[0012] Such as figure 1 As shown, the shockproof and easy-to-maintain optical fiber connector described in the embodiment of the present invention is mainly composed of a plug 1 , a socket 2 , and an optical fiber ferrule 3 interconnected. Its internal structure is as figure 2 As shown, the fiber optic ferrule assembly is as image 3 shown. Each optical fiber ferrule is designed through integration. After the optical fiber and ferrule are polished, they are installed into the housing of the connector plug and socket through special tools, which solves the problems of anti-vibration of the connector and convenient on-site maintenance.

[0013] Such as figure 2 As shown, a shockproof and easy-to-maintain optical fiber connector includes an interconnected plug and socket device. After the plug optical fiber ferrule assembly 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com