Temperature control method and system

A temperature control method and technology of temperature control system, applied in temperature control, control/regulation system, non-electric variable control and other directions, can solve the problems of temperature shock, poor overshoot performance, relatively large temperature fluctuation, etc. Strong, accurate control and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

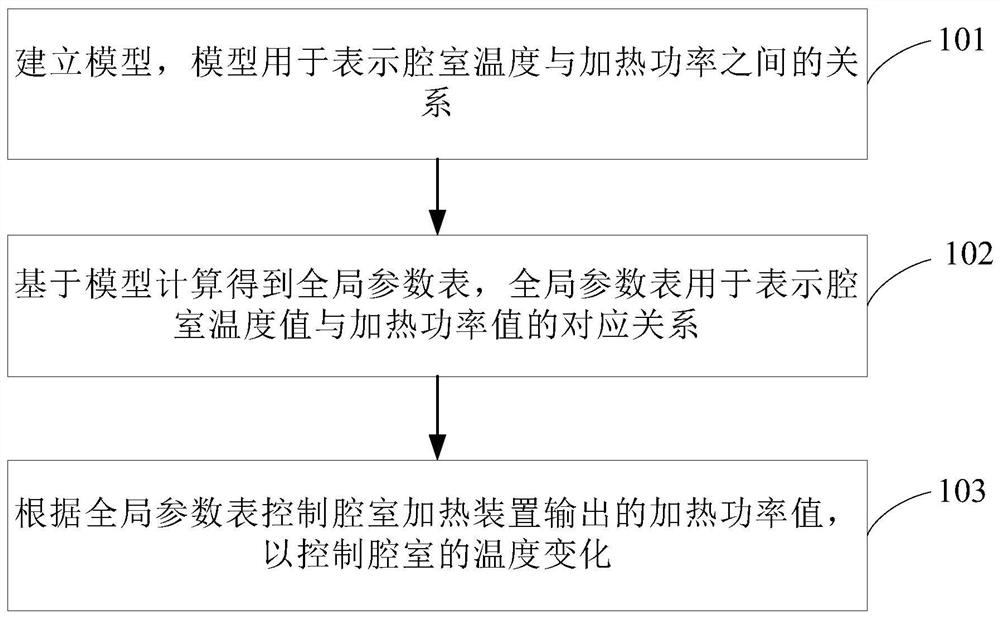

[0050] Such as figure 2 Shown is a flow chart of the temperature control method provided by the embodiment of the present invention, including the following steps:

[0051] Step 101: Establish a model, the model is used to represent the relationship between the chamber temperature and the heating power.

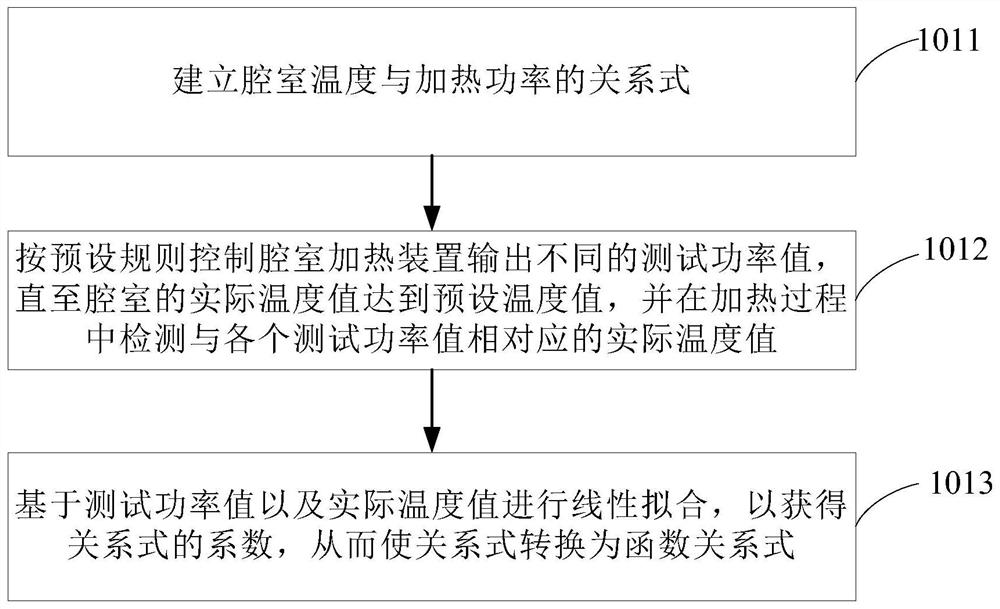

[0052] Specifically, the model building step: control the chamber heating device to output different test power values to the chamber, obtain the actual temperature value of the chamber corresponding to each test power value, and according to the relationship between the actual temperature value and the test power value Modeling.

[0053] Specifically, both the test power value and the heating power are the output power of the chamber heating device, and the test power value is only the heating power of the chamber heating device during the test process, and the output power of the chamber heating device.

[0054] Step 102: Calculate and obtain a global parameter table b...

Embodiment 2

[0073] Such as Figure 6 Shown is another flow chart of the temperature control method provided by the embodiment of the present invention, including the following steps:

[0074] Step 201: Establish a model, which is used to represent the relationship between the chamber temperature and heating power.

[0075] Step 202: Calculate and obtain a global parameter table based on the model, and the global parameter table is used to represent the corresponding relationship between the chamber temperature value and the heating power value.

[0076] Step 203: Control the heating power value output by the chamber heating device according to the global parameter table, so as to control the temperature change of the chamber.

[0077] Step 204: Obtain the actual value of the chamber temperature and the actual value of the heating power within the set period.

[0078] Specifically, the set period may be determined according to process requirements, for example, the set period is 1 h.

...

Embodiment 3

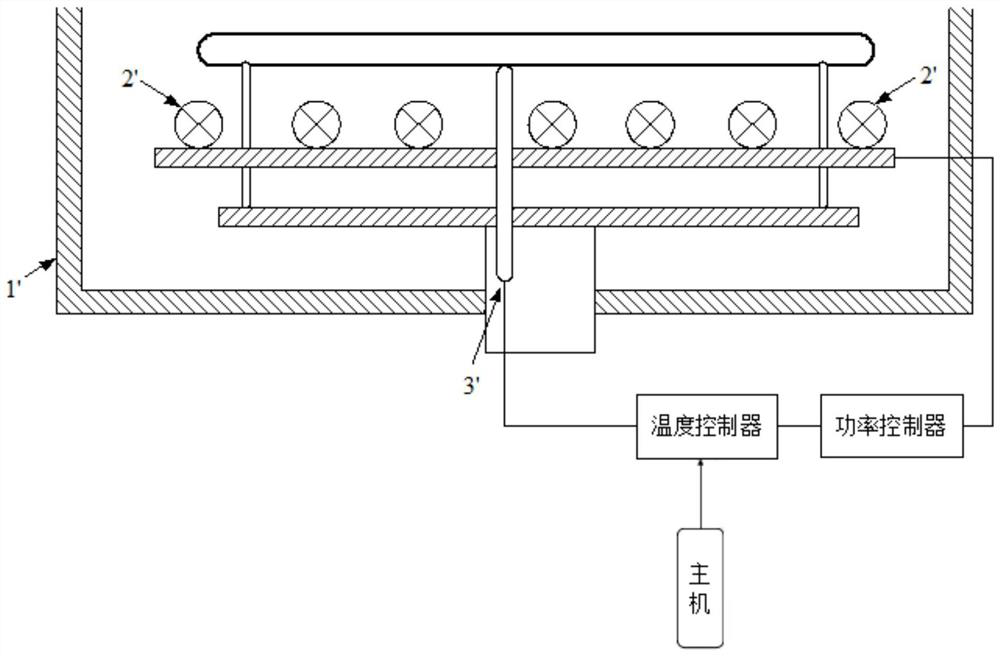

[0086] For the above temperature control method, the present invention also provides a temperature control system, such as Figure 7 As shown, the temperature control system includes: a chamber heating device. The system also includes: upper computer and lower computer;

[0087] The upper computer is used to control the chamber heating device to output different test power values to the chamber, and obtain the actual temperature value of the chamber corresponding to each test power value; establish a model based on the relationship between the actual temperature value and the test power value, A model is used to represent the relationship between chamber temperature and heating power. The upper computer is also used to calculate the global parameter table based on the model, and output control signals to the lower computer according to the global parameter table; the global parameter table is used to represent the corresponding relationship between the chamber temperature v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com