Steam heat supply network steam trap inspection and discharge operation scheduling method and operation scheduling system

A technology of net steam trap and scheduling method, applied in the field of smart energy and industrial Internet, can solve the problems of steam leakage in the pipeline, long opening time of the steam trap, and inability to completely cover the inspection area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

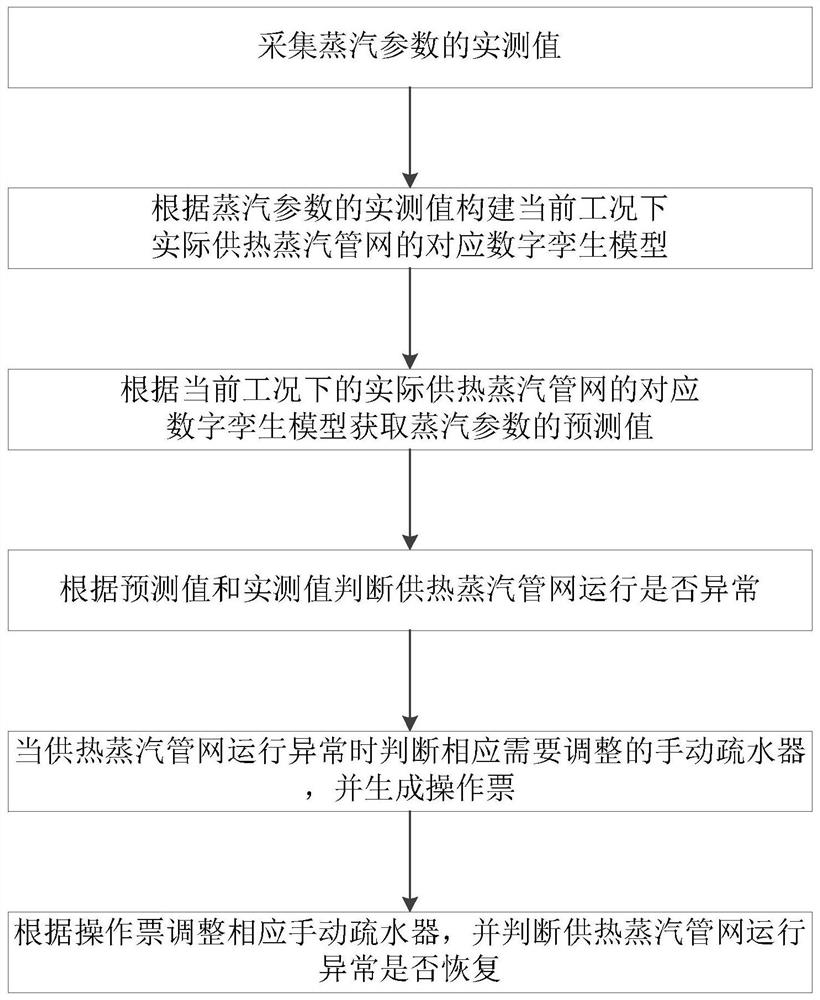

[0077] figure 1 It is a flow chart of the method for dispatching the patrol inspection and discharge operation of the steam heating network steam trap according to the present invention.

[0078] Such as figure 1 As shown, this embodiment 1 provides a method for dispatching inspection and discharge operation of steam heating network steam traps, including: collecting actual measured values of steam parameters; constructing actual heating steam pipe networks under current operating conditions based on the actual measured values of steam parameters Corresponding to the digital twin model; obtain the predicted value of the steam parameter according to the corresponding digital twin model of the actual heating steam pipe network under the current working conditions; judge whether the heating steam pipe network is operating abnormally according to the predicted value and the measured value; when the heating steam pipe When the network operation is abnormal, determine the correspond...

Embodiment 2

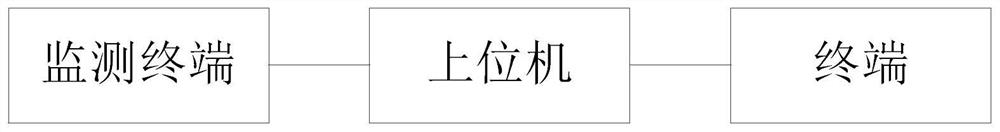

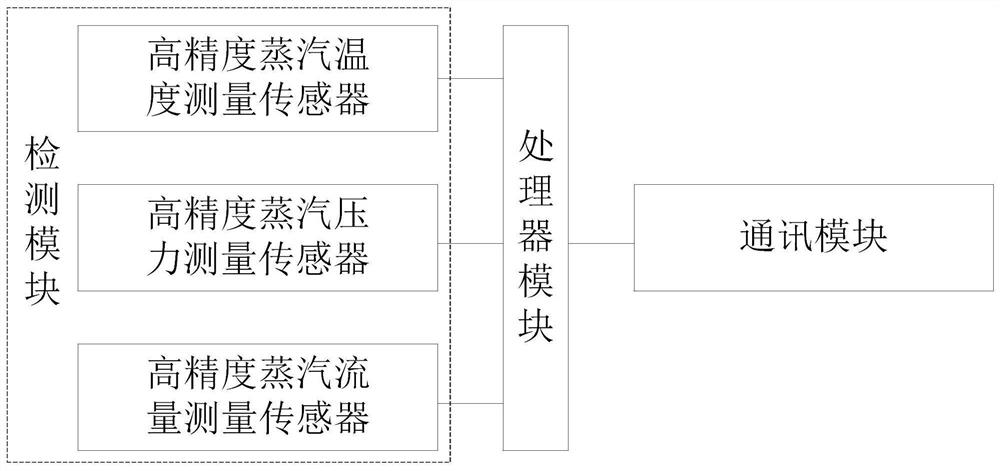

[0112] figure 2 It is the principle block diagram of the patrol inspection and discharge operation scheduling system for steam heating network steam traps involved in the present invention.

[0113] Such as figure 2 As shown, on the basis of embodiment 1, this embodiment also provides a steam heating network steam trap inspection and discharge operation scheduling system, including: a monitoring terminal, an upper computer, and a terminal; the upper computer may but not Limited to the use of computers, etc.; the terminal can be, but not limited to, mobile phones, Pads, etc.; the monitoring terminal is suitable for detecting the actual measured values of the steam parameters of the heating steam pipe network and sending the actual measured values to the upper computer; the upper computer is suitable To judge whether the heating steam pipe network is operating abnormally based on the actual measured value, when the heating steam pipe network is operating abnormally, an operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com