Enameled skin removing device for flat copper wire

A flat copper wire and mounting seat technology, applied in the direction of electromechanical devices, cable installation devices, cable installation, etc., can solve problems such as increased repair welding, affecting the welding quality of 192 welding spots of high-efficiency generator stators, and affecting the power generation performance of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

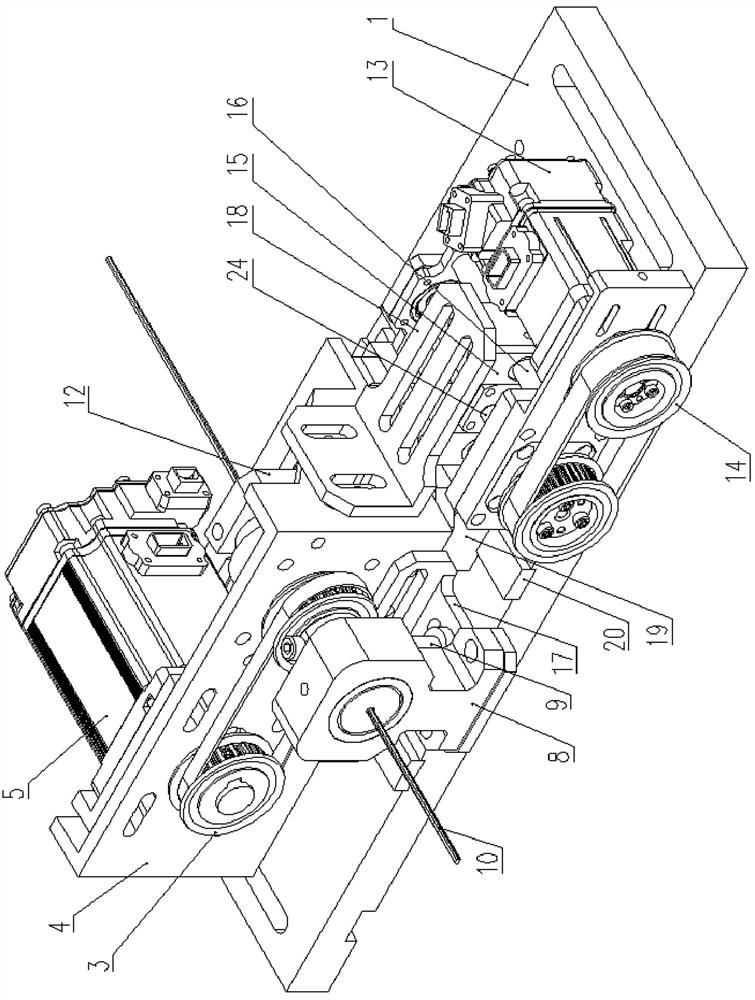

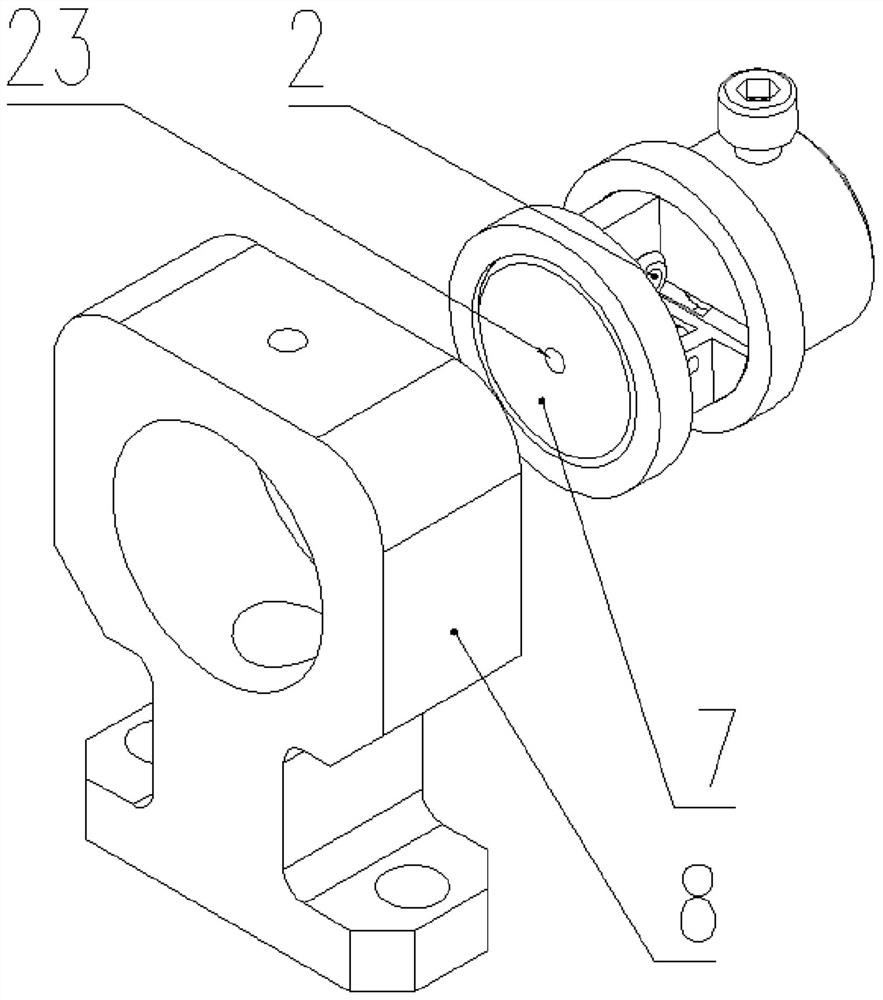

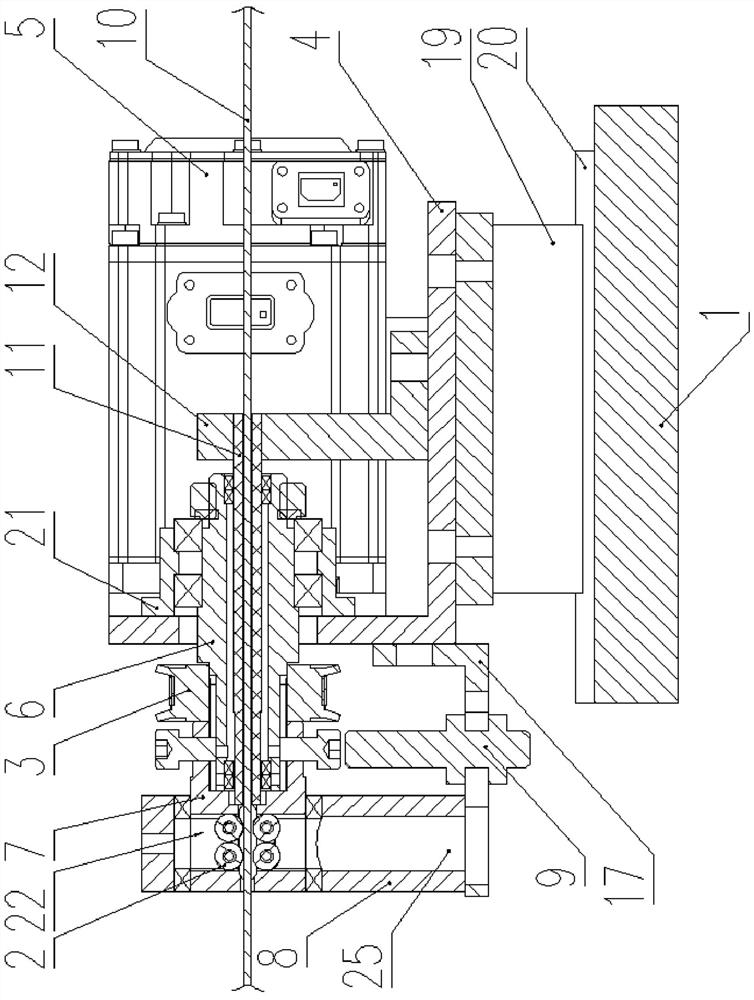

[0026] A kind of embodiment of flat copper wire stripping device of the present invention:

[0027] see Figure 1-Figure 4, a flat copper wire paint remover, comprising a base plate 1, a paint remover is slidably fitted on the base plate 1, and a displacement drive device is fixedly installed, and the paint remover includes a mounting seat 4, a second motor 5, a second Pulley transmission mechanism 3, hollow rotating shaft 6, cutter body 7, cutter body support seat 8, a bearing seat 21 is installed by screw on the described mounting seat 4, and described hollow rotating shaft 6 is supported in this bearing seat 21 by bearing, makes The hollow shaft 6 can rotate in the bearing housing 21 . One end of the hollow rotating shaft 6 extends out of the mounting base 4 and is connected with the rotating shaft of the second motor 5 installed on the mounting base 4 through the second pulley transmission mechanism 3 , and the driven wheel circumference of the hollow rotating shaft 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com