Pneumatic pollination control device for large row ratio hybrid rice seed production

A control device and hybrid rice technology, applied in the field of machinery, can solve the problems of insufficient pollination rate, uncertain wind direction and wind force, and only one pollen chance for pollen, and achieve the effect of increasing the pollination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

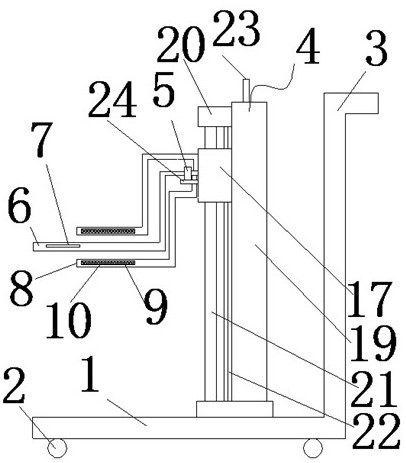

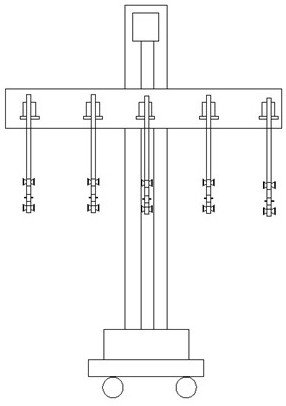

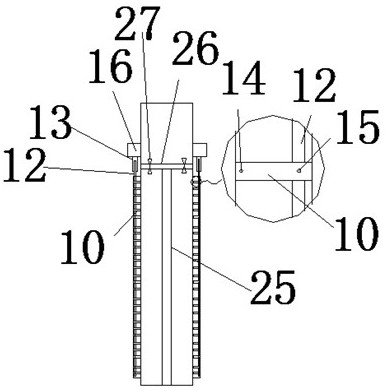

[0019] Such as figure 1 and 2 The described pneumatic pollination control device for large-row ratio hybrid rice seed production comprises a base 1, a roller 2 is installed at the bottom of the base 1, and a push handle 3 is connected to the base 1; a lifting device 4 is installed on the base 1, and a lifting device 4 An air pump 5 is installed on the top; the air outlet end of the air pump 5 is connected with an L-shaped pollination pipe 6, and strip-shaped air nozzles 7 are formed on both sides of the L-shaped pollination pipe 6; L-shaped pollen collection is installed above and below the L-shaped pollination pipe 6 Pipe 8, L-shaped pollen collection pipe 8 both sides are formed with strip-shaped trumpet-shaped pollen collection mouth 9; Pollen collection mouth 9 places are equipped with filter screen 10; L-shaped pollen collection pipe 8 communicates with the air inlet of air pump 5; Inside the nozzle 7, a plurality of wind guide vanes 10 arranged parallel to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com