Video display welding helmet and welding equipment

A welding helmet and video display technology, which is applied in the field of video display welding helmets and welding equipment, can solve the problems of high difficulty and high risk of welding work, and achieve the effect of improving safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

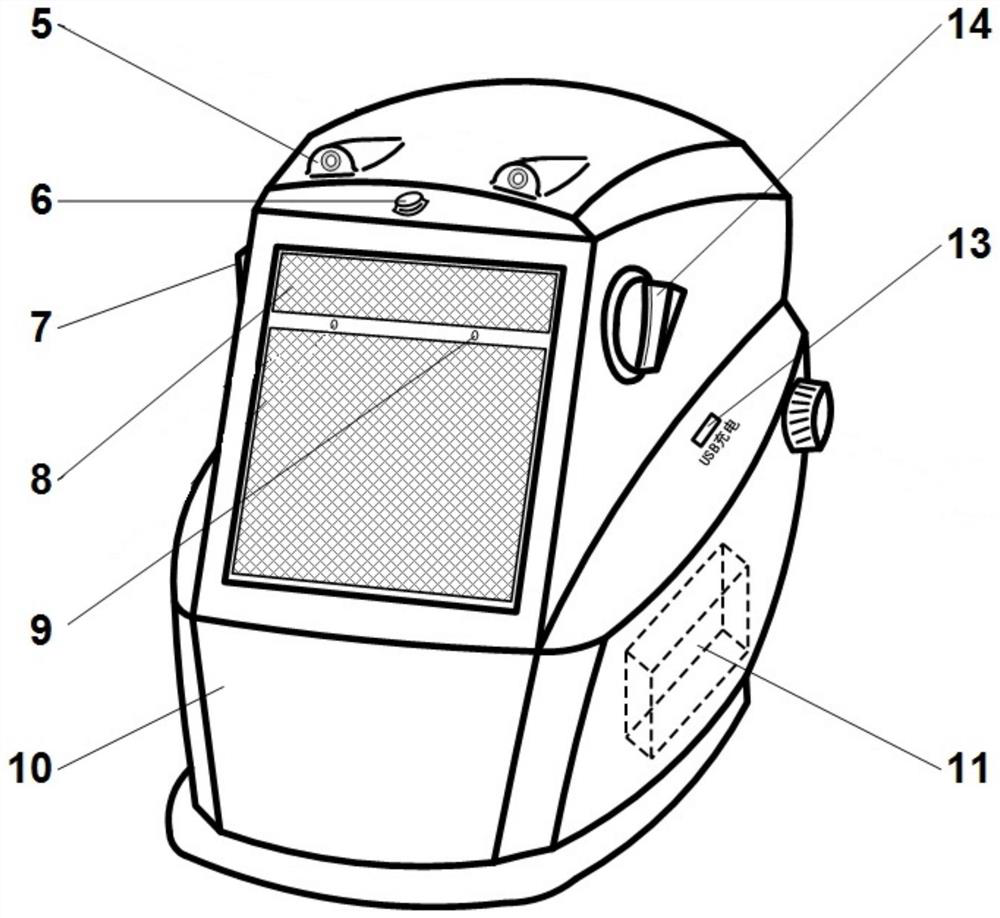

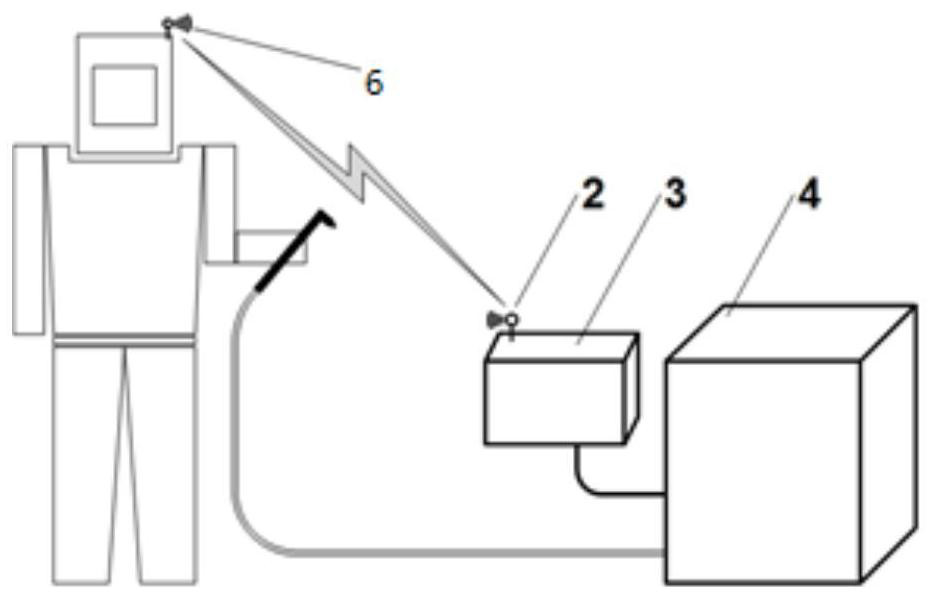

[0034] see figure 1 with figure 2 , a video showing a welding helmet, including:

[0035] A helmet 10, the helmet 10 is provided with a display device, a controller, a camera 5 and a first wireless communication device 6;

[0036] The controller is connected with the display device, the camera 5 and the first wireless communication device 6, and the controller controls the first wireless communication device 6 to transmit the video data taken by the camera 5;

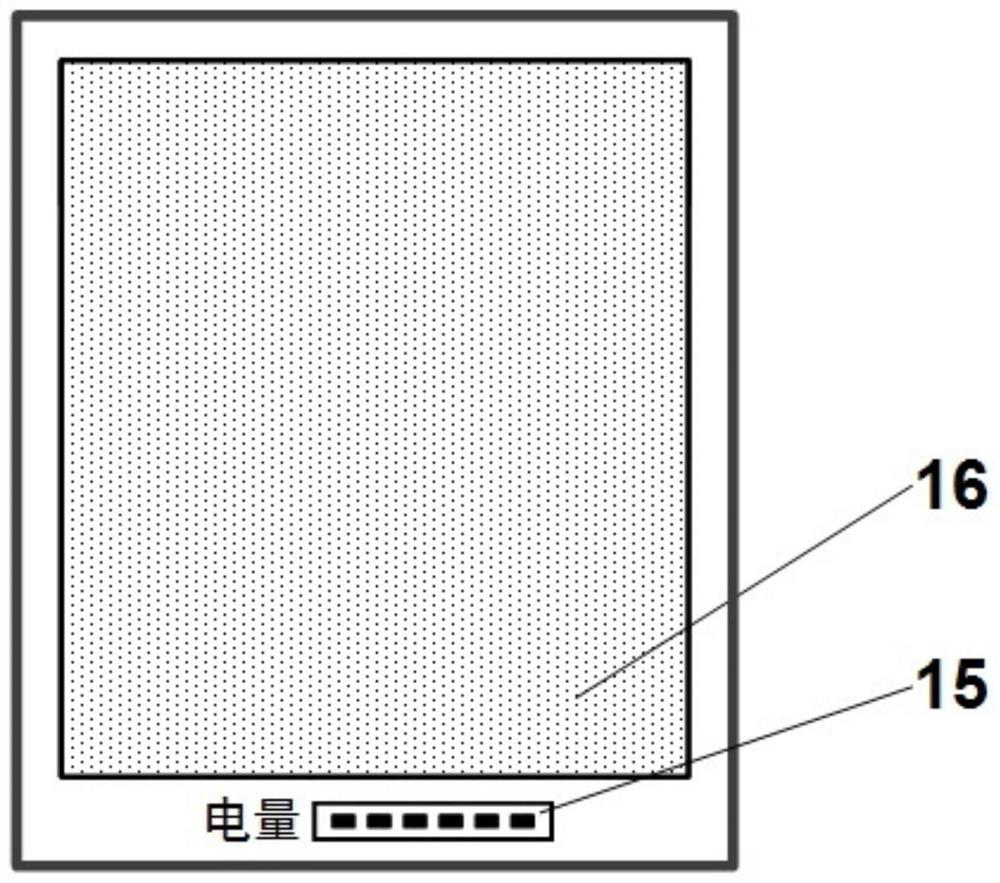

[0037] The display device displays the video signal received by the first wireless communication device 6 . Wherein the helmet 10 adopts a semi-open four-sided protection design. Two cameras 5 are installed on the outside and top of the helmet 10. The camera 5 is a high-definition welding camera 5. The display device is used to display video images such as the operation process of the manual welding scene and the shape of the molten pool. , as well as graphic information such as welding parameter data and welding eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com