Method for synthesizing dye-doped organic-inorganic composite latex through double in-situ emulsion copolymerization

An inorganic composite, dual in situ technology, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of light fastness, poor weather fastness, cumbersome and other problems, achieve high light fastness, uniform distribution, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] According to the feeding ratio and conditions shown in Table 1 and Table 2, the double in-situ emulsion was prepared by one-step copolymerization to form dye-doped organic-inorganic composite latex. The steps are as follows:

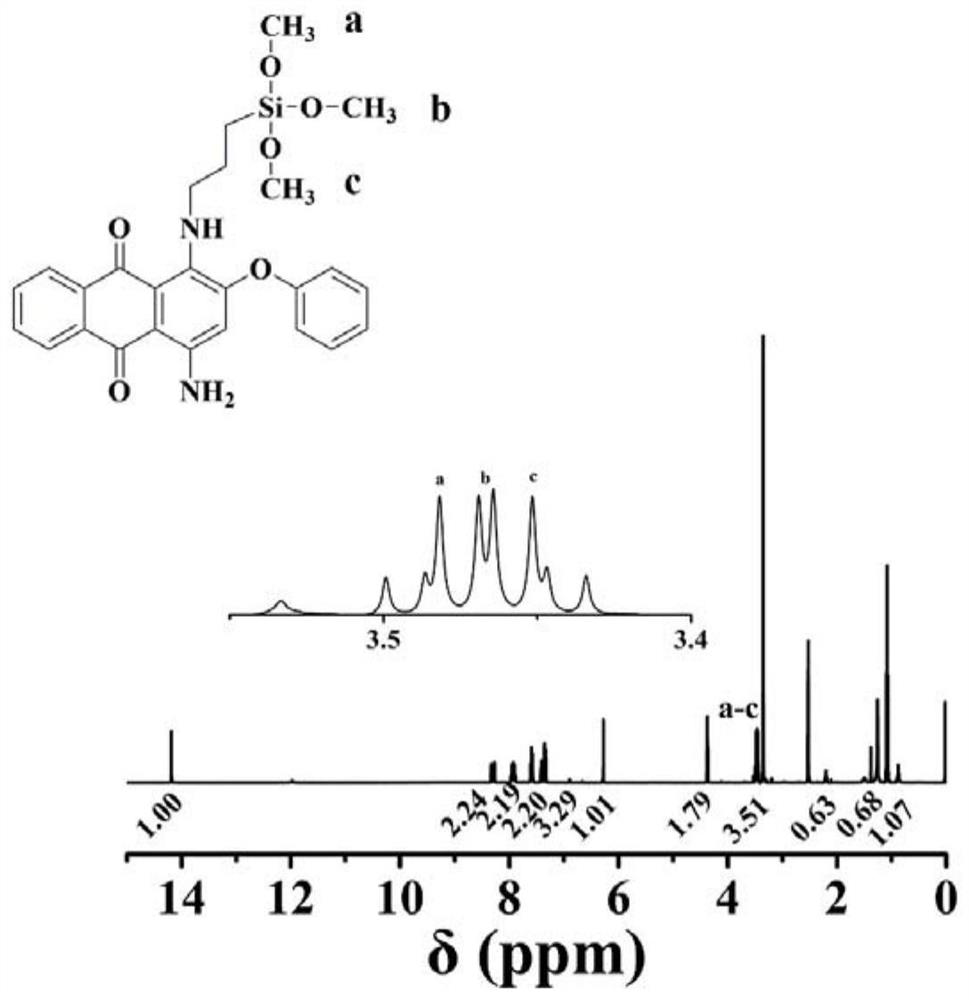

[0046] In 30g of chloroform solvent, add 0.18g of disperse red 3B, 0.36g of 3-3-isocyanatopropyltrimethoxysilane and 2 drops of dibutyltin dilaurate, and react at room temperature for 22h at 25°C to obtain silane-modified Disperse Red 3B, the structure of silane-modified Disperse Red 3B is as follows:

[0047]

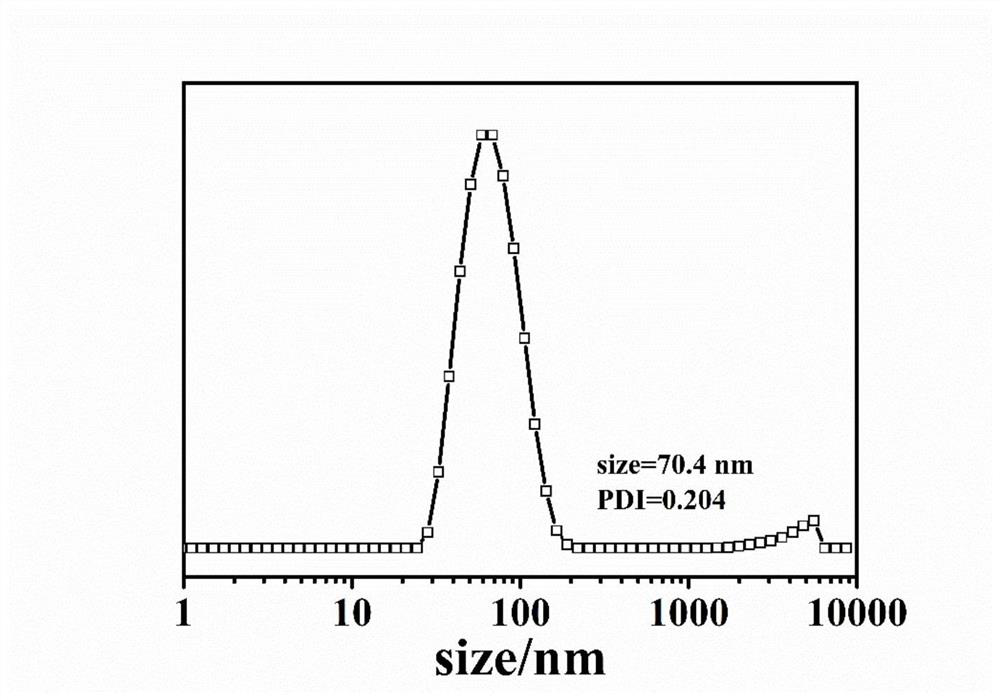

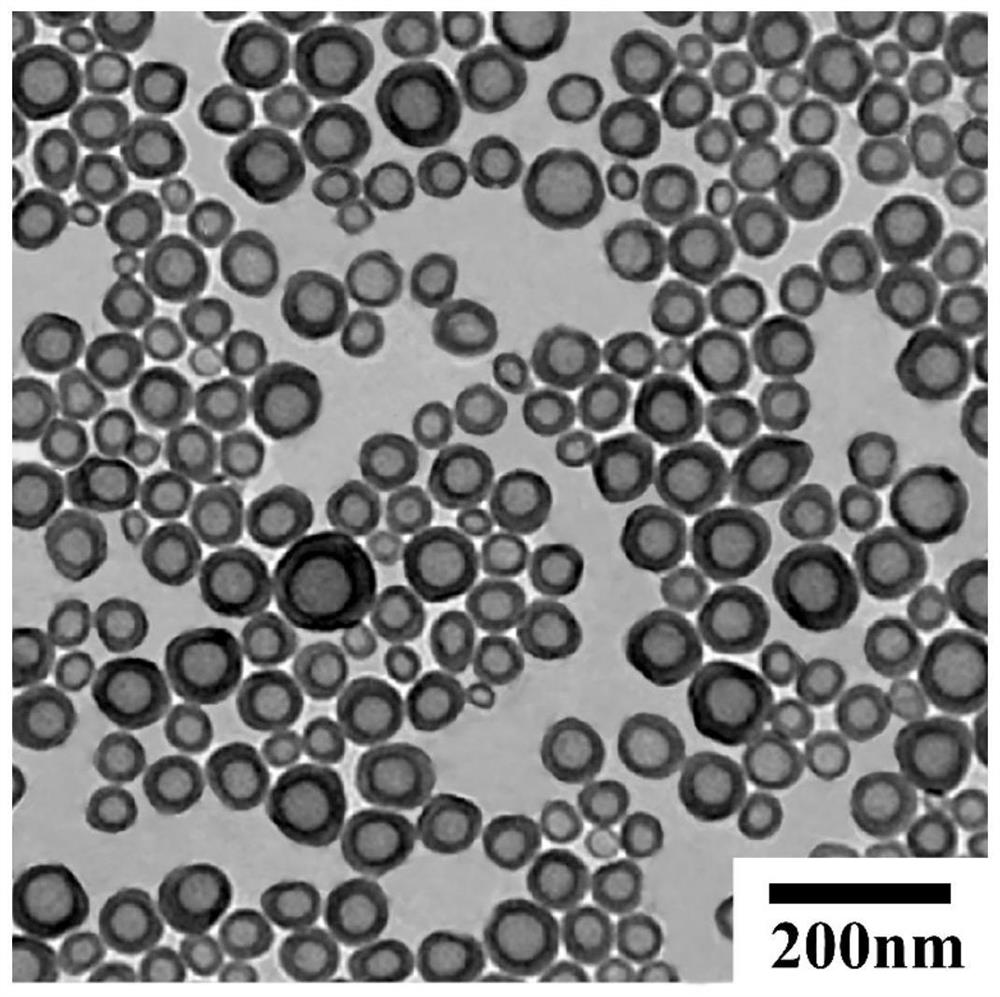

[0048] Such as Figure 4 As shown, according to the feeding ratio and ultrasonic conditions shown in Table 1 and Table 2, silane-modified dyes, tetraethyl orthosilicate (TEOS), 3-(trimethoxysiloxane) propane were added to the long-necked flask respectively. Base-2-methyl-2-acrylate (MPS), styrene (St), butyl acrylate (BA), azobisisobutylcyanide (AIBN), n-hexadecane (HD), n-octane and n-hexanol, to completely dissolve the silane-modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com