Automatic compression packaging equipment for pop cans

A pop-up can, automatic technology, applied in the direction of press, mobile filter element filter, separation method, etc., can solve the problems of inconvenient operation, low work efficiency, laborious, etc., to achieve convenient operation, high work efficiency, and avoid offset. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

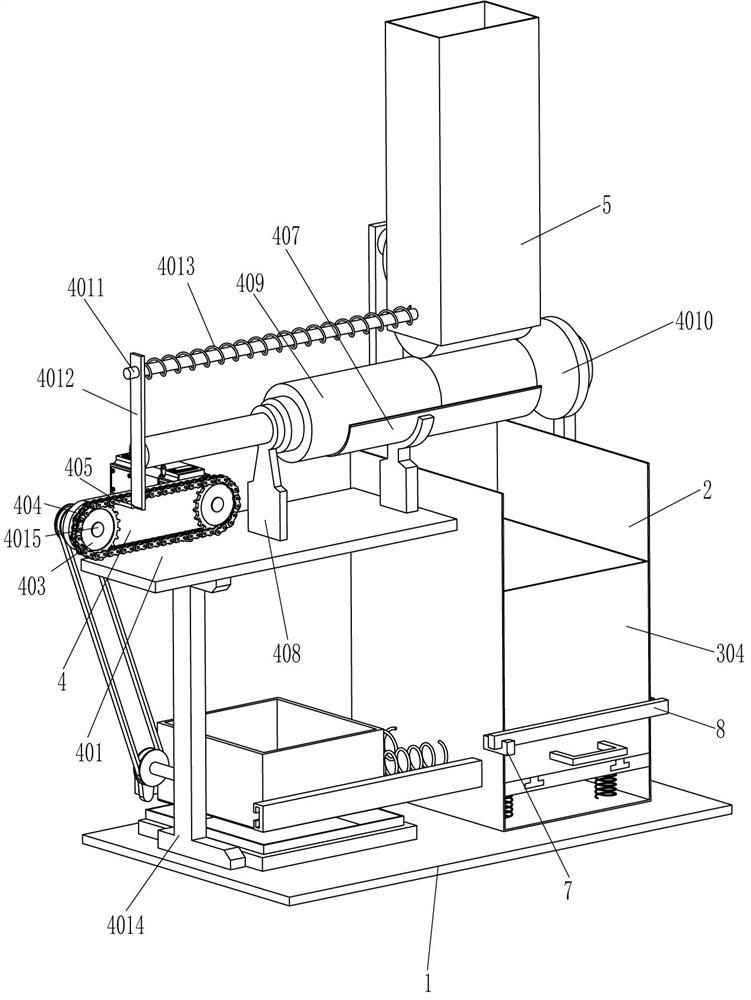

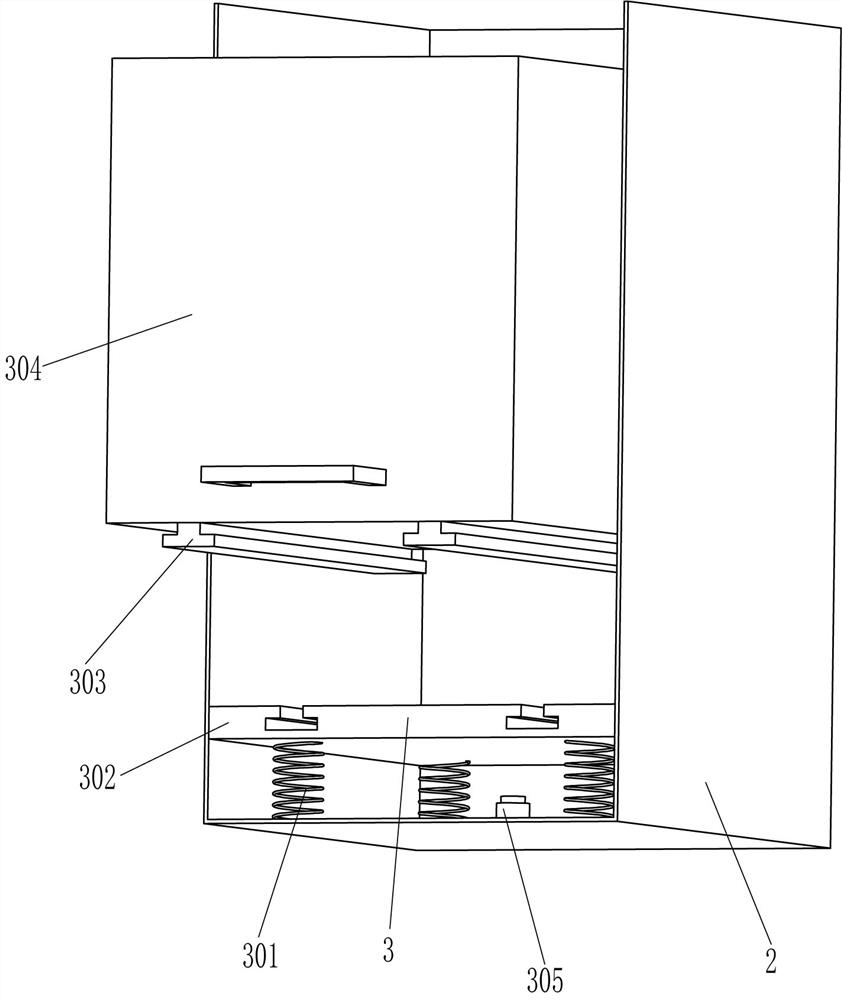

[0020] see Figure 1-Figure 3 , an automatic compression and packaging equipment for cans, including a bottom plate 1, a shell 2, a collection mechanism 3, a compression mechanism 4, a placing cylinder 5, a fixed seat 6, a stopper 7 and a swing rod 8. The top right side of the bottom plate 1 is fixed with a Housing 2, a collection mechanism 3 is arranged in the housing 2, a fixed seat 6 is fixedly connected to the front side of the lower part of the outer right side of the housing 2, and a swing rod 8 is rotatably connected to the fixed seat 6, and the swing rod 8 is connected with the collection mechanism 3 Matching, a stopper 7 is fixed on the front side of the lower part of the outer left side of the housing 2, and the stopper 7 is in contact with the swing rod 8. A compression mechanism 4 is arranged between the top left side of the bottom plate 1 and the outer upper part of the housing 2. A placing cylinder 5 is fixed in the middle of the upper part of the outer rear side...

Embodiment 2

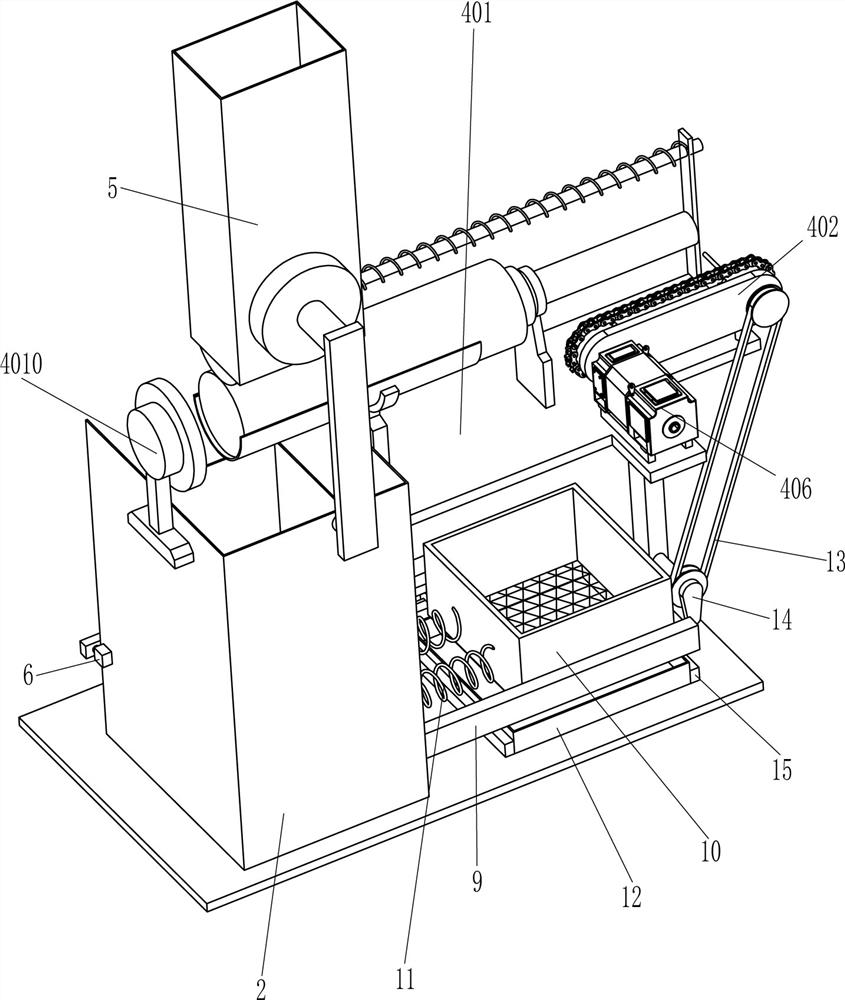

[0027] see figure 2 , Compared with Embodiment 1, the main difference between this embodiment is that in this embodiment, it also includes a guide assembly 9, a screening frame 10, a third spring 11, a frame body 12, a transmission assembly 13 and a cam 14. A guide assembly 9 is connected to the front and rear sides of the lower part of the side surface, and a screening frame 10 is slidably arranged between the inner sides of the guide assemblies 9 on the front and rear sides. A third spring 11 is connected between, the lower part of the rear side of the bracket 4014 is rotatably connected with a cam 14 through a transmission shaft, a transmission assembly 13 is connected between the transmission shaft and the rear end of the left rotation shaft 4015, the transmission assembly 13 is a belt drive, and the cam 14 and the The screening frame 10 is in contact with each other, and a frame body 12 is placed at the rear left side of the top of the bottom plate 1 , and the frame body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com