Hydro-thermal treatment device for shale processing

A technology of hydrothermal treatment and shale, which is applied in the field of shale processing, can solve the problems affecting the effect of hydrothermal treatment, etc., and achieve the effect of enhancing the effect of hydrothermal treatment, enhancing the effect of buffering, and enhancing the effect of air pressure dispersion and buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

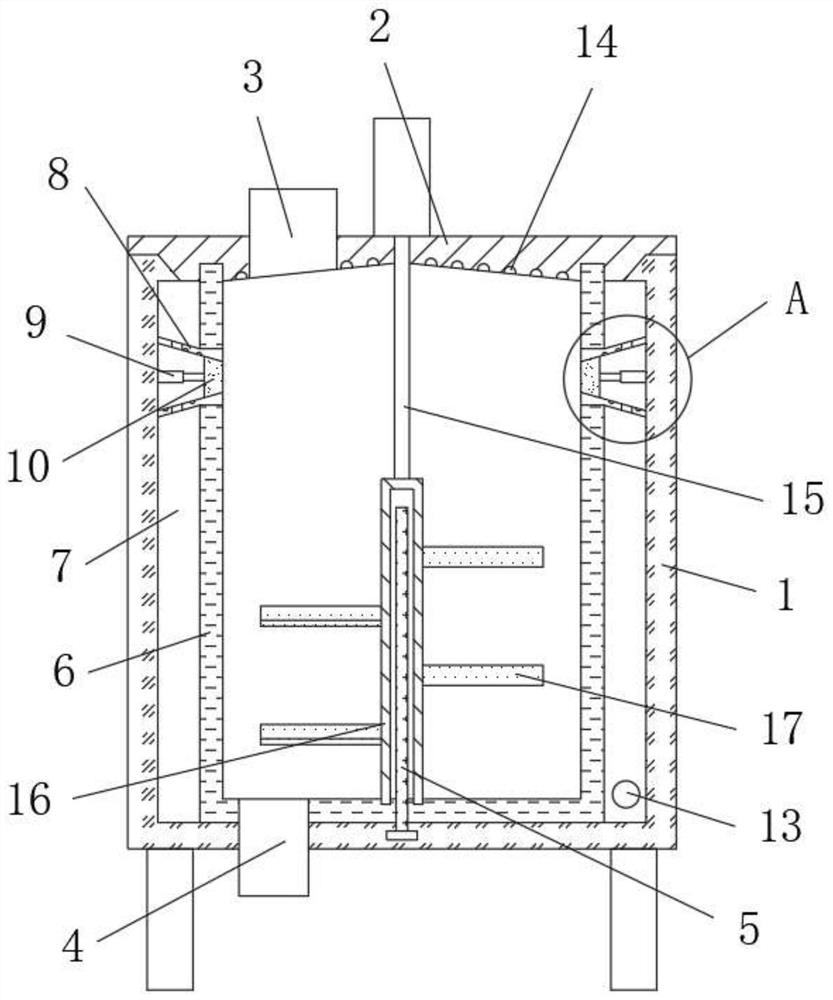

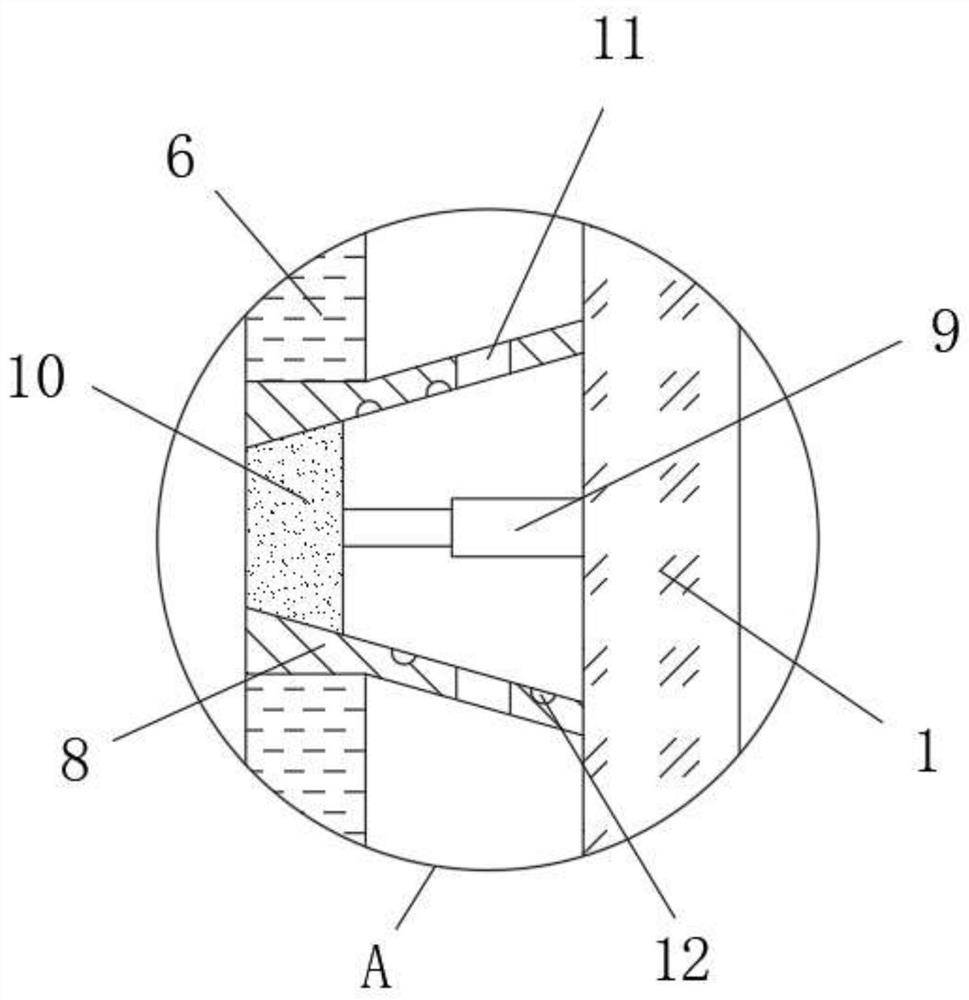

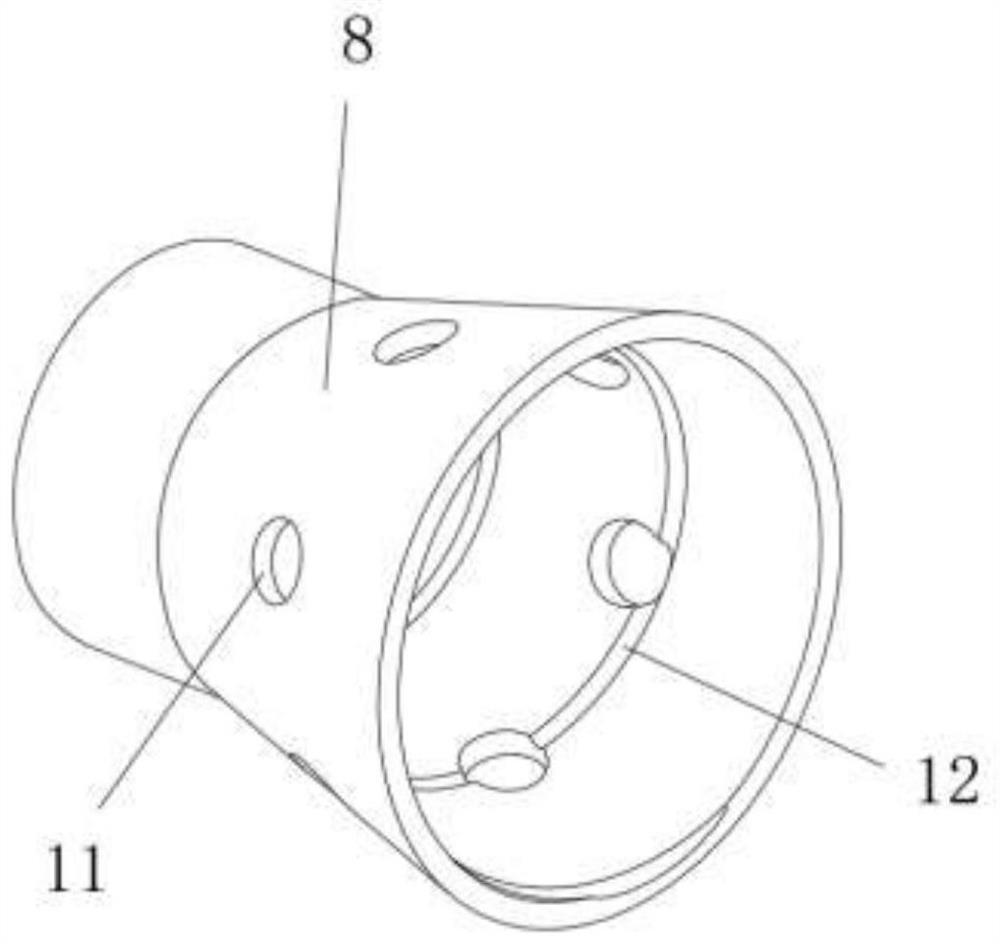

[0027] refer to Figure 1-4 , a water heat treatment device for shale processing, comprising a treatment cylinder 1, the top of the treatment cylinder 1 is fixed with a sealing cover plate 2, and the top and bottom of the treatment cylinder 1 are respectively provided with a feed pipe 3 and a liquid discharge pipe 4, and the treatment cylinder 1 1 is provided with a pressure relief pipe, the processing cylinder 1 is provided with a heating element 5 and a stirring mechanism, the inner wall of the bottom of the processing cylinder 1 is fixed with an inner cylinder 6 with an open top, and the top of the inner cylinder 6 and the sealing cover plate 2 Sealing arrangement, an auxiliary chamber 7 is provided between the outer wall of the inner cylinder 6 and the inner wall of the processing cylinder 1, the top of the outer wall of the inner cylinder 6 is provided with a circular array of through grooves, and the inner wall of the groove is fixed with a connecting cylinder 8, and the ...

Embodiment 2

[0033] refer to Figure 5 , a water heat treatment device for shale processing, the bottom of the inner wall of the auxiliary chamber 7 is slidingly connected with a connecting ring 19, and a plurality of springs 20 are connected between the bottom outer wall of the connecting ring 19 and the bottom inner wall of the auxiliary chamber 7, and the top of the connecting ring 19 There are grooves 21 distributed in an annular array, and the cross section of the sipe 21 is set in a V-shaped structure.

[0034] When in use, the elastic force of the spring 20 is used to make the air chamber in the auxiliary chamber 7 have a certain range of variation, and the multiple grooves 21 on the top of the connecting ring 19 are used to enhance the cushioning effect of the connecting ring 19, so as to enhance the air pressure in the auxiliary chamber 7. The effect of scatter buffering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com