Conversion connection structure of fabricated structural column variable cross-section joint steel bar and implementation method

A technology for converting connection and implementation methods, applied in structural elements, building components, building structures, etc., can solve the problems of low longitudinal steel assembly accuracy, poor bending force of steel bars, etc. , the effect of broadening the field of application and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

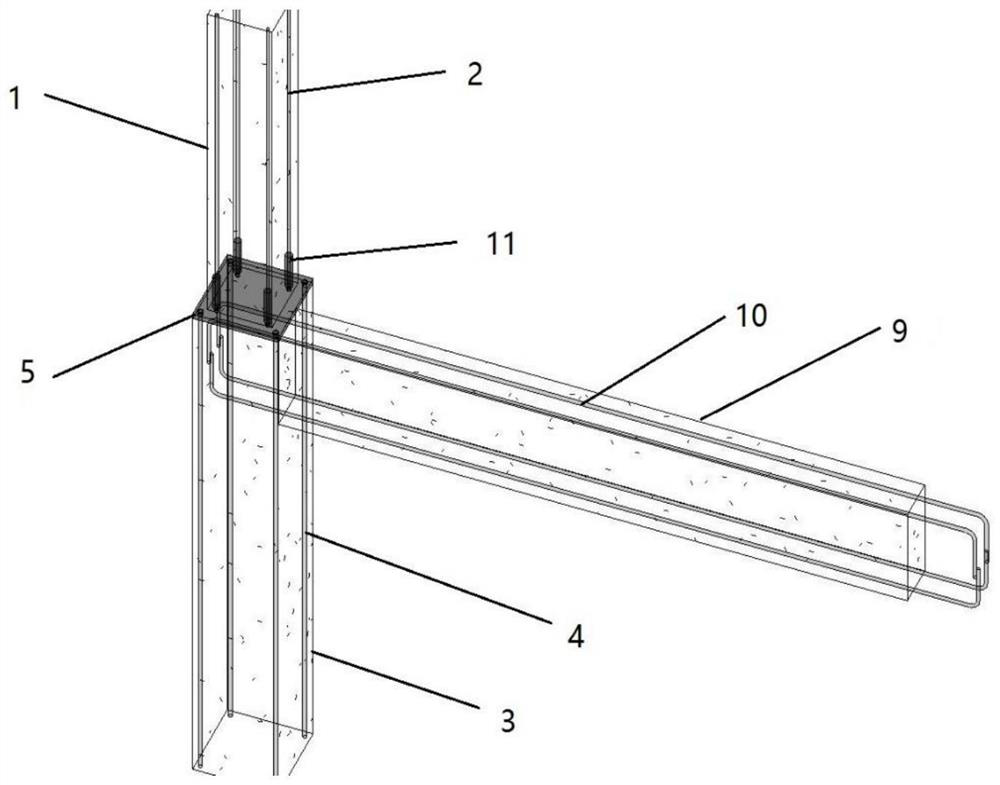

[0040] Embodiment one: by Figure 1 to Figure 8 Given, the conversion connection structure of the prefabricated reinforced concrete structural column with variable cross-section joint steel bars, including the upper section column 1 and the lower section column 3, the lower section column 3 is connected to the frame beam 9, the upper section column 1 and the lower section column A conversion steel plate 5 is arranged between the columns 3, and the first connection hole 6, the second connection hole 7 and the reserved hole 13 for pouring are reserved on the surface of the conversion steel plate 5. material, vibrating and exhaust to provide the cut-in, the grouting sleeve 11 corresponding to the second connection hole 7 is set in the upper section column 1, the grouting sleeve is assembled before the concrete pouring of the section column, the grouting sleeve 11 and the Short ribs 8 are arranged between the second connection holes 7, and the connection between the upper section ...

Embodiment 2

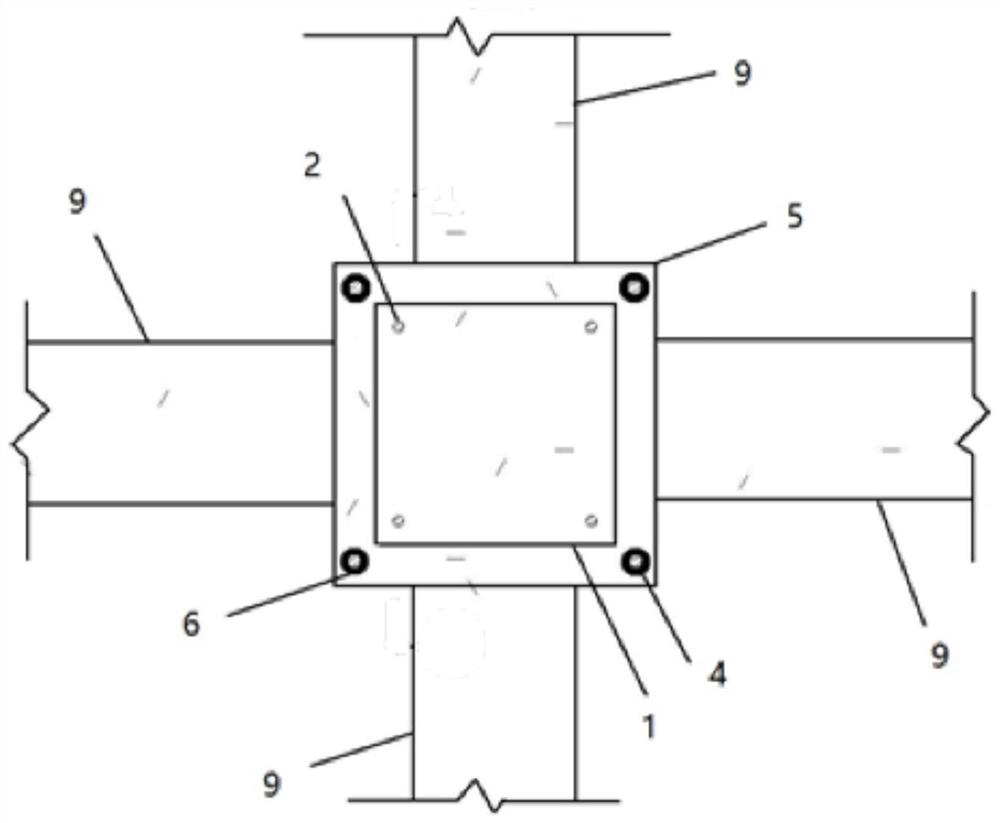

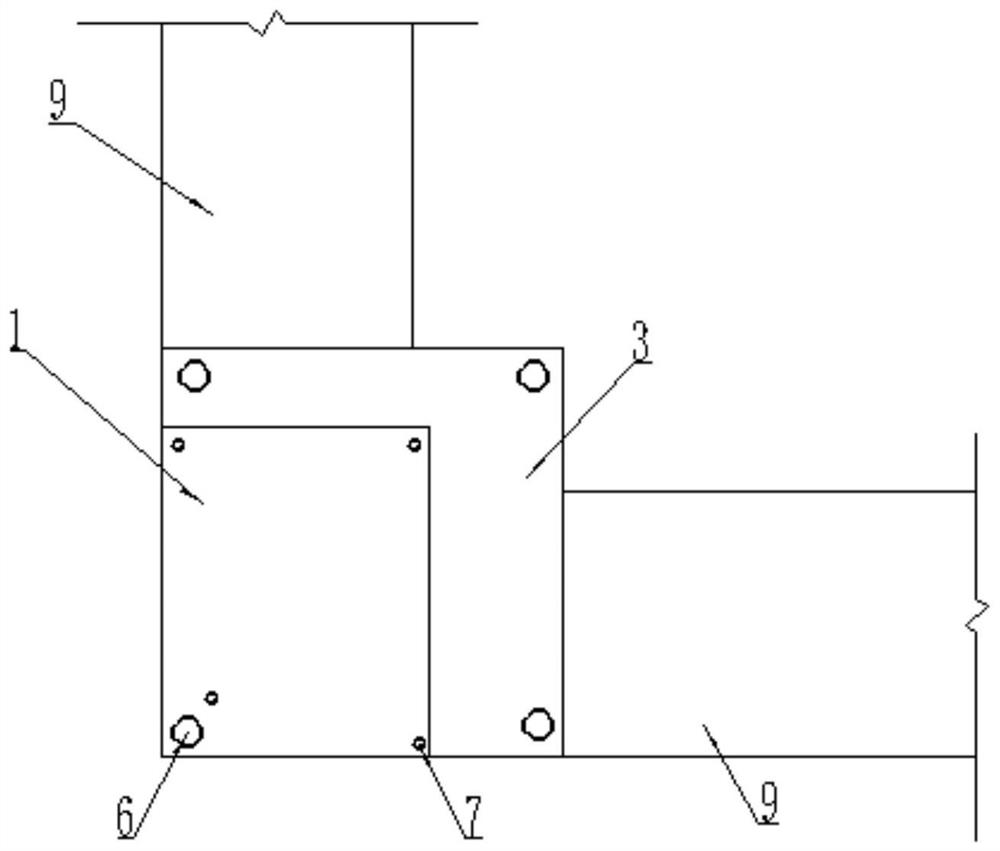

[0041] Embodiment 2: On the basis of Embodiment 1, there are multiple first connecting holes 6 and they are evenly distributed on the four corners of the conversion steel plate 5 corresponding to the lower section column 3, and there are multiple second connecting holes 7 And evenly distributed on the conversion steel plate 5 at the position corresponding to the four corners of the upper section column 1, the upper section column 1 is placed in the center of the lower section column 3 to keep concentric with the lower section column 3, and the frame beam 9 is in a ten-fold shape around the lower section column. This type of joint column connection is used for the middle joint column in the concrete frame system with variable cross-section columns. The two sides of the upper joint column 1 are respectively kept corresponding to the two sides of the lower joint column 3, and the frame beam 9 is in the lower joint. The two sides of the section column 3 that are not corresponding t...

Embodiment 3

[0042] Embodiment 3: On the basis of Embodiment 2, the first connecting hole 6 is a conical hole with a wide top and a narrow bottom, which facilitates the insertion of the second longitudinal steel bar 4 and converts the diameter of the first conical connecting hole 6 on the steel plate. According to the second longitudinal steel bar of the lower section column, the diameter is appropriately enlarged and reserved; the second connection hole 7 is a rounded table hole with a narrow top and a wide bottom, and is inserted with the short rib 8 to convert the second connection of the rounded table shape on the steel plate The aperture of the hole 7 is properly enlarged and reserved according to the diameter of the short rib, and the short rib 8 and the second connecting hole 7 are welded and fixed by means of perforated plug welding, and the second longitudinal steel bar 4 and the first connecting hole 6 are fixed by perforating Welding and fixing by plug welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com