Three-degree-of-freedom electromagnetic vibration isolation device based on magnetic repulsion positive and negative stiffness parallel connection

A technology with positive and negative stiffness and degrees of freedom, used in magnetic springs, shock absorbers, non-rotational vibration suppression, etc., can solve the problem of low utilization of magnetic materials, improve design flexibility, reduce manufacturing costs, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

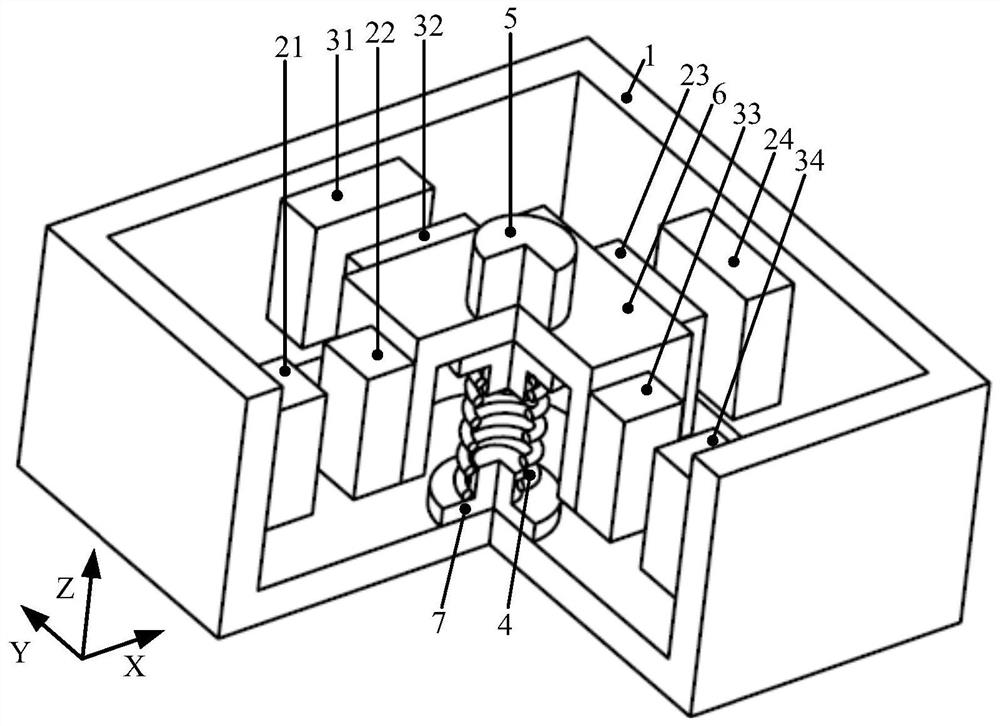

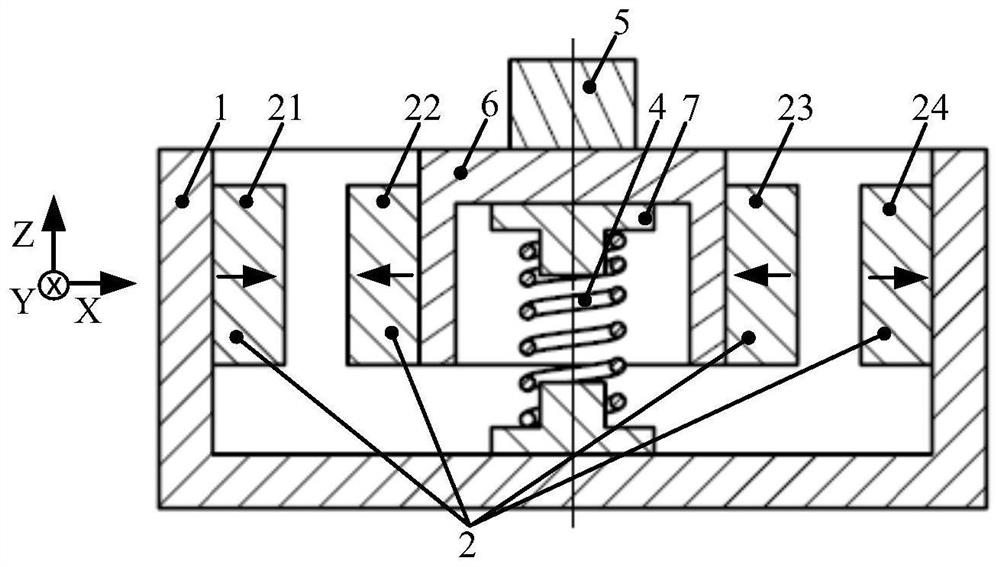

[0030] As a specific implementation manner, the third fixed magnet 31, the third moving magnet 32, the fourth moving magnet 33 and the fourth fixed magnet 34 are magnetized along the horizontal Y axis, and the magnetization direction of the third fixed magnet 31 is the same as that of the third fixed magnet 31. The magnetization directions of the four fixed magnets 34 are the same, and opposite to those of the third moving magnet 32 and the fourth moving magnet 33 .

[0031] As a specific implementation manner, the third fixed magnet 31 , the third moving magnet 32 , the fourth moving magnet 33 and the fourth fixed magnet 34 are magnetized in the same direction along the horizontal X-axis or the Z-axis.

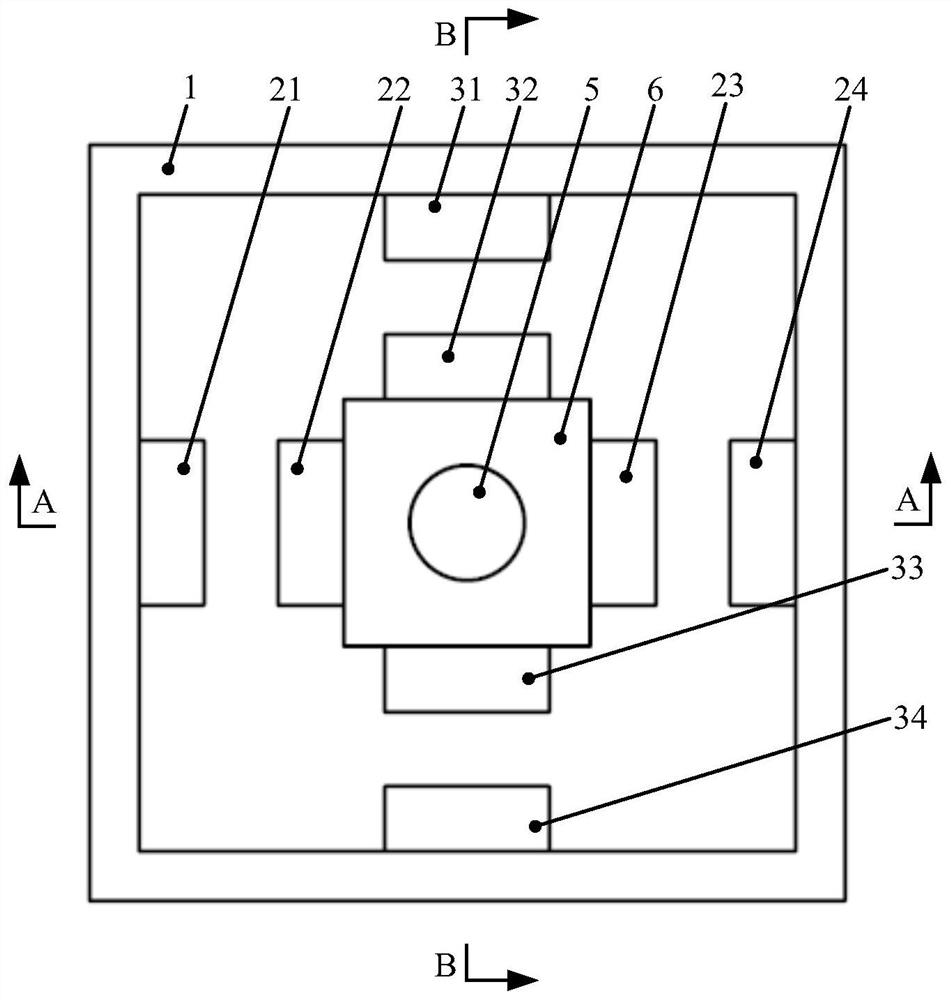

[0032] As a specific implementation, the overall structure of the three-degree-of-freedom electromagnetic vibration isolation device based on the parallel connection of positive and negative stiffnesses based on magnetic repulsion is axisymmetric, and the fixing holes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com