Tunnel smooth blasting structure and blasting method

A technology of smooth blasting and tunneling, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems of reducing internal and external interaction, unstable blasting effect of smooth blasting structure, etc., and achieve the effect of enhancing the overall strength and blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

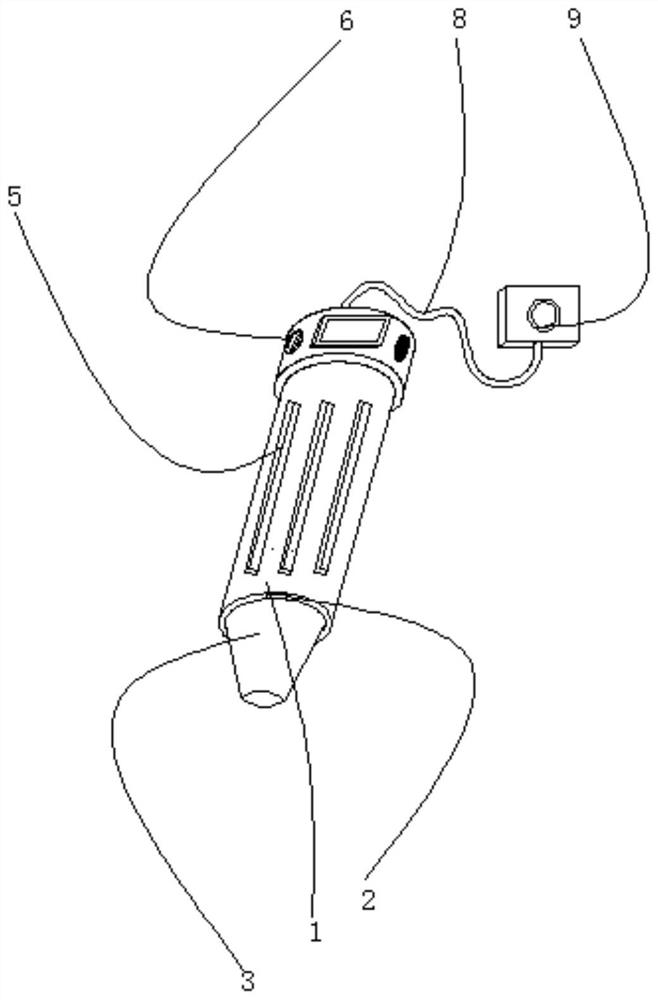

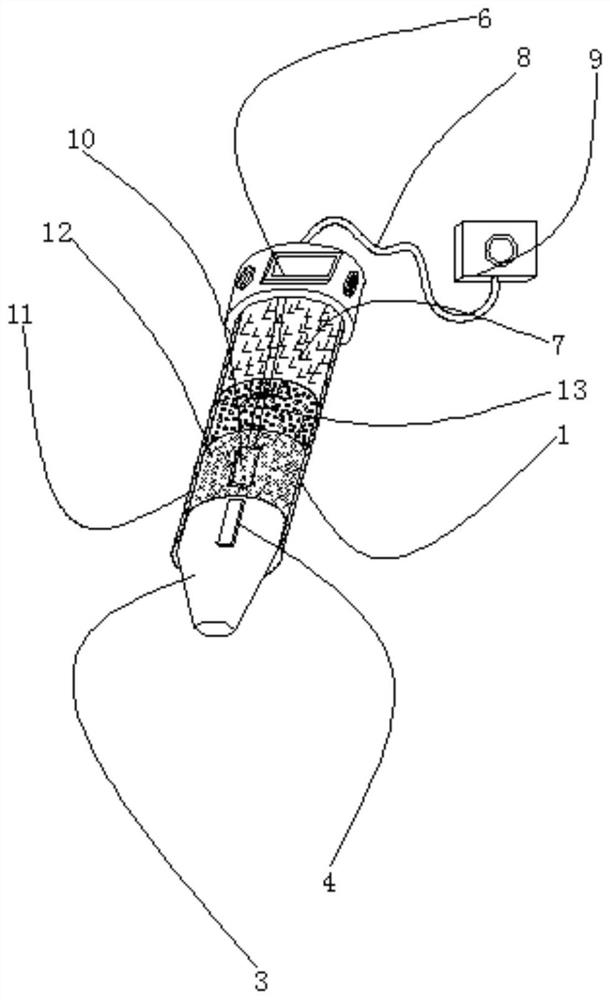

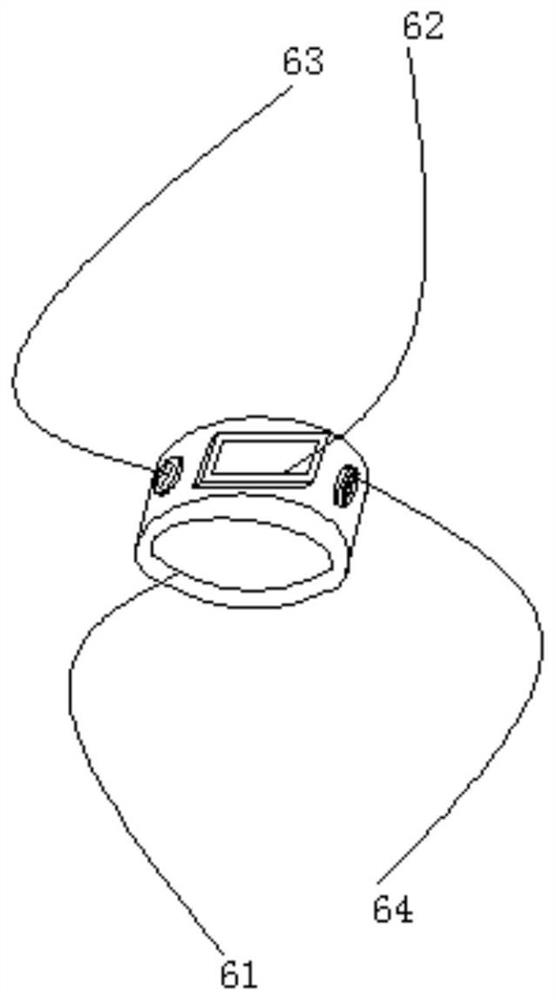

[0024] as attached figure 1 to the attached image 3 shown:

[0025] The present invention provides a tunnel smooth blasting structure, comprising a gun body 1, characterized in that a gun head 3 is installed at the bottom end of the gun body 1, a clamping plate 4 is welded on the side of the gun head 3, and a control plate 4 is fixedly installed at the top of the gun body 1. Mechanism 6, the control mechanism 6 comprises a cylinder 61, the bottom of the cylinder 61 is fixedly connected with the bottom of the gun body 1, and the front of the cylinder 61 is fixedly installed with an electronic sign 62, and the inner side of the bottom of the gun body 1 is provided with a gunpowder layer 12 , the inner side of the powder layer 12 is provided with a detonating block 10, and the top of the powder layer 12 is provided with a buffer layer 13 located on the inside of the gun body 1, and the top of the buffer layer 13 is provided with a gun mud layer 7 located on the inside of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com