Display substrate and preparation method thereof, display panel and display device

A technology for display substrates and display panels, used in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., can solve the problems of small line width and line spacing of power supply lines, and achieve improved display uniformity, small power supply voltage difference, The effect of reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] refer to Figure 6 , the embodiment of the present invention also discloses a method for preparing a display substrate, including:

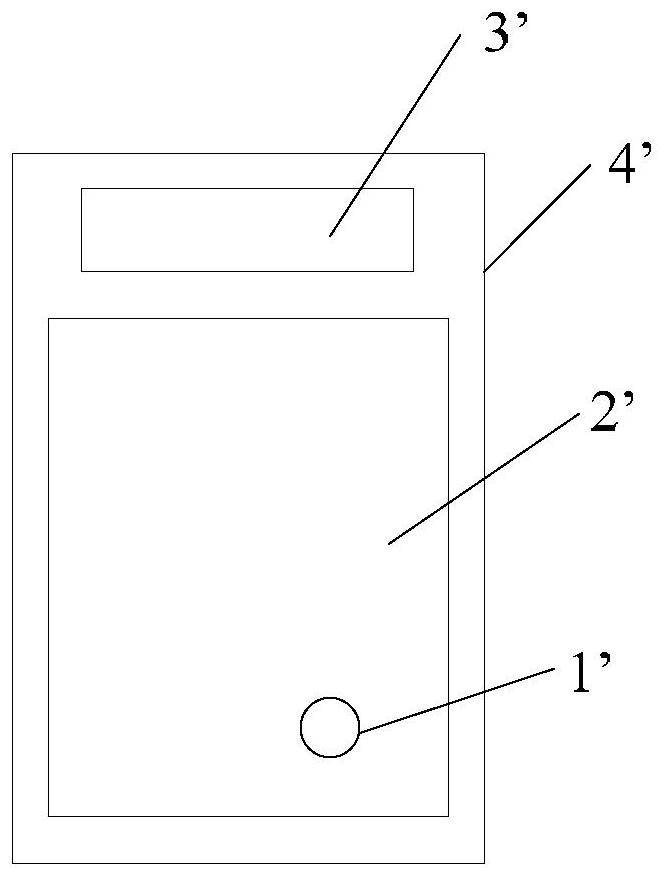

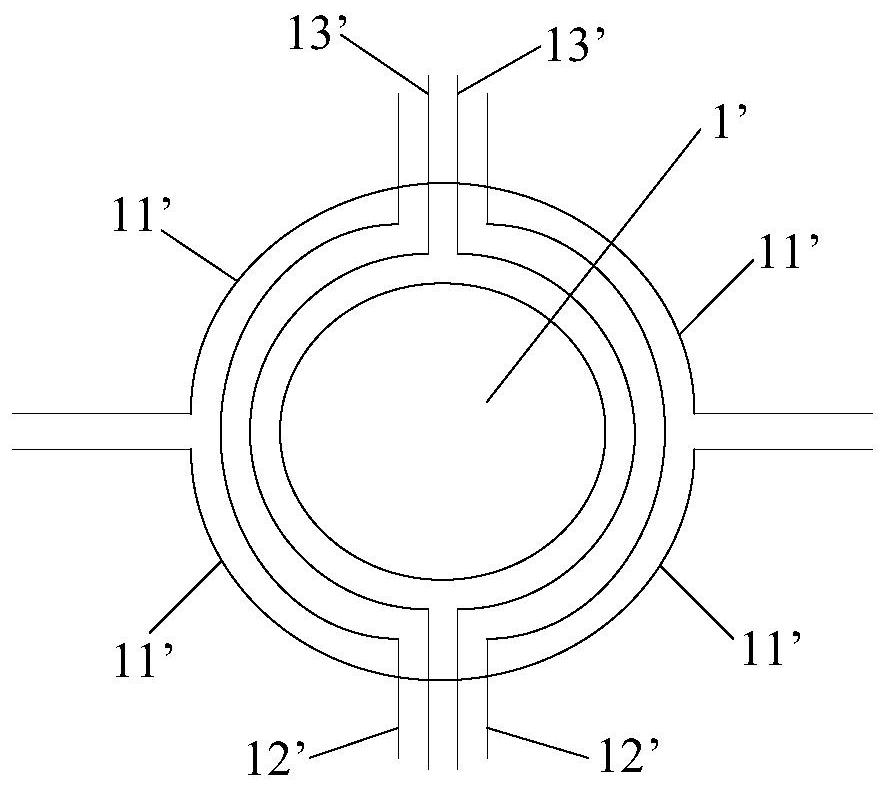

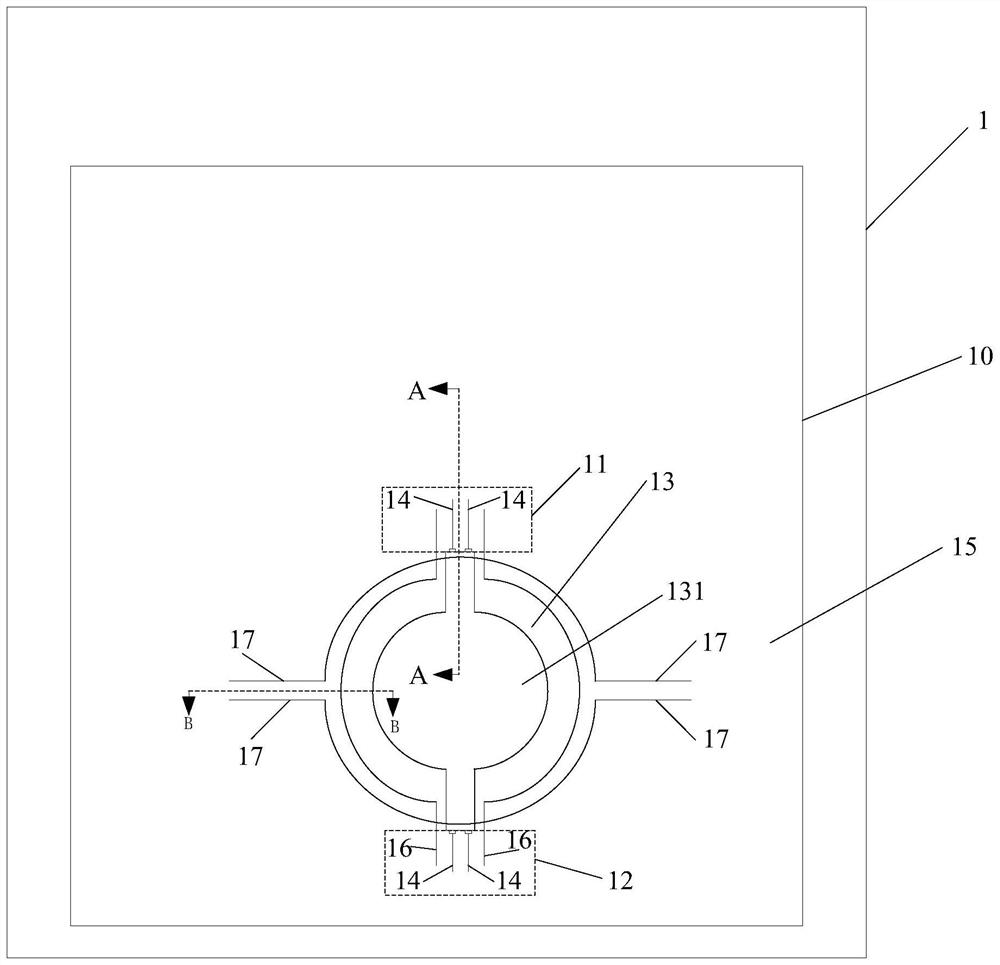

[0051] Step 610, providing a substrate corresponding to the display area. The substrate includes a first wiring area, a second wiring area, and an under-screen camera area. The under-screen camera area is located between the first wiring area and the second wiring area.

[0052] Step 620, forming an inorganic layer and a first power line on both the first wiring area and the second wiring area of the substrate.

[0053] Step 630, forming an inorganic layer and a first flat layer on the under-screen camera area of the substrate close to the first wiring area and the second wiring area, and forming a second flat layer on the first power line.

[0054] Step 640, forming an overlapping layer on the first power line between the first planar layer and the second planar layer.

[0055] Step 650 , forming a pixel defining layer on the overla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com