Deformer iron core cleaning device

A technology for transformer iron core and cleaning device, which is applied in the directions of transportation and packaging, cleaning methods and utensils, chemical instruments and methods, etc. Reliable structural design, high automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

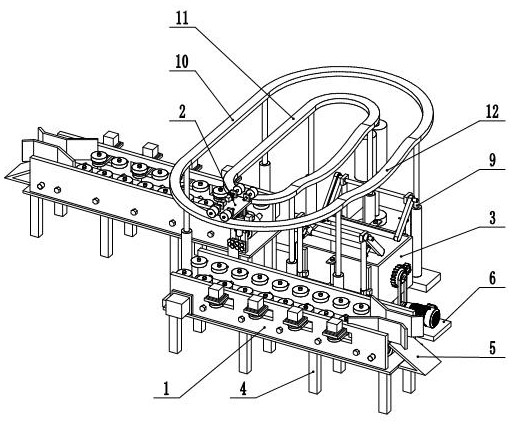

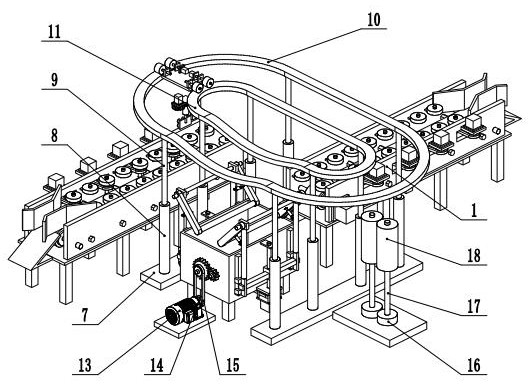

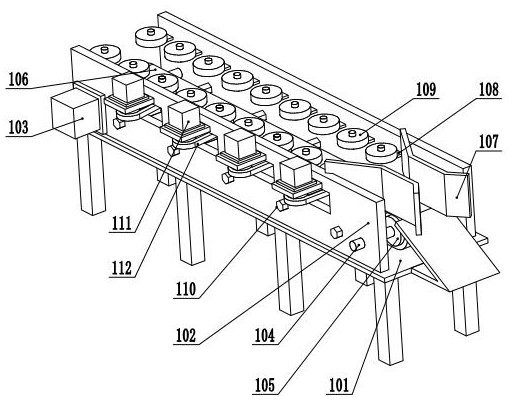

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6A transformer iron core cleaning device shown includes an iron core conveying mechanism 1, a moving conveying mechanism 2, an iron core cleaning mechanism 3, a support column 4, a slide table 5, a motor fixing frame 6, a pillar foundation 7, and a fixed support column 8 , adjustable support and fixed frame 9, outer ring moving slide rail 10, inner ring moving slide rail 11, arc-shaped slide rail 12, three-phase asynchronous motor 13, pulley 14, belt 15, bearing seat 16, long shaft 17, cleaning brush 18.

[0025] The iron core conveying mechanism 1 is installed at a fixed price, the leftmost front position of the overall mechanical structure, the mobile conveying mechanism 2 is located above the iron core conveying mechanism 1 and above the entire mechanical structure, and is used for moving between parts, and the iron core cleaning mechanism 3 is installed and fixed on the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com