Hydraulic punching machine

A technology of hydraulic punch and hydraulic cylinder, which is applied to the cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. and other problems to achieve the effect of improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

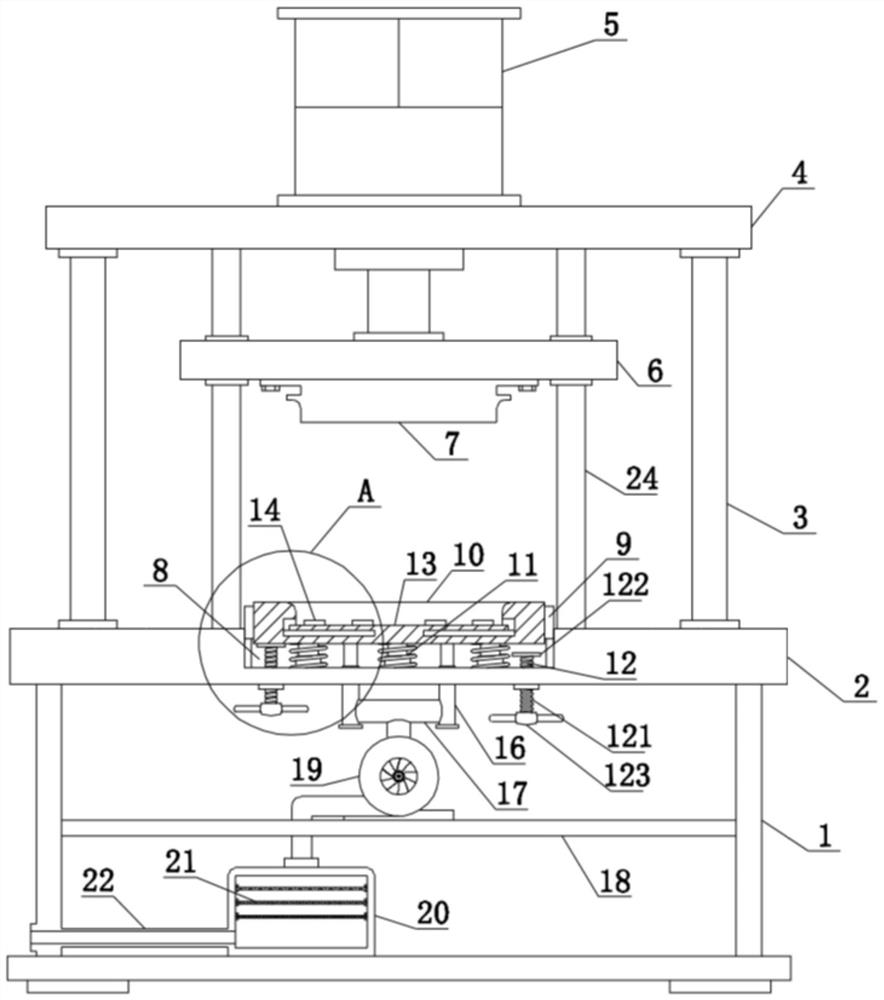

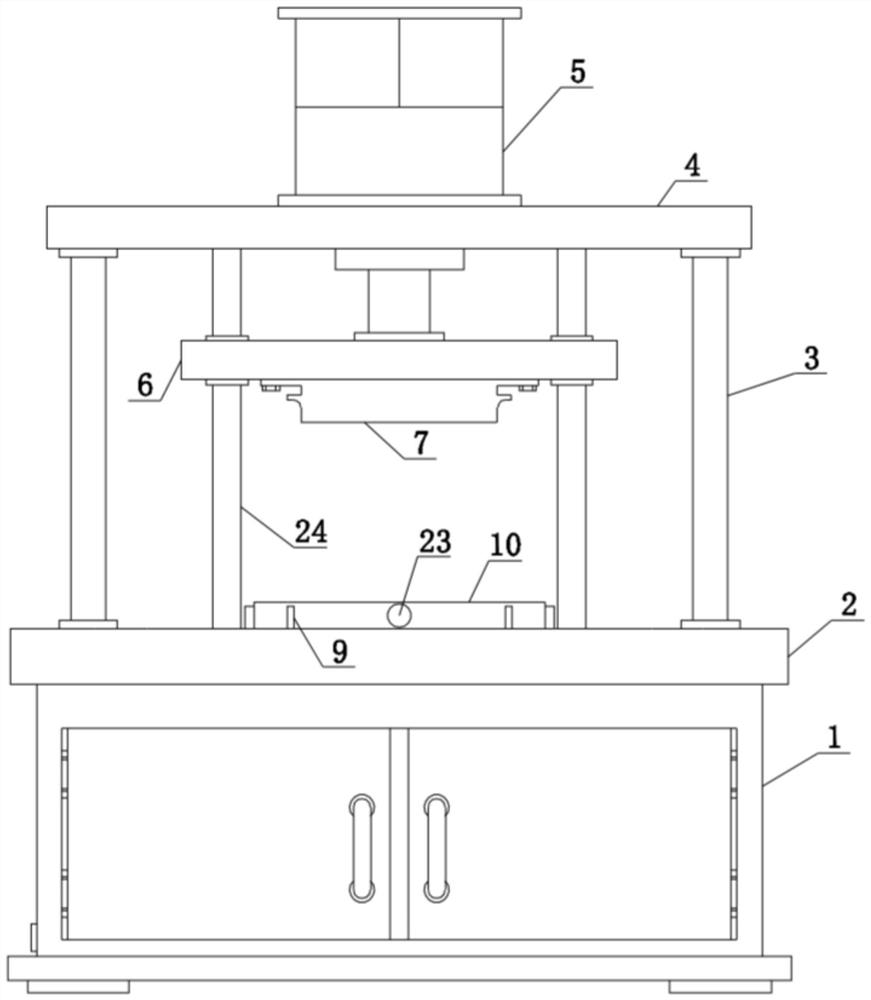

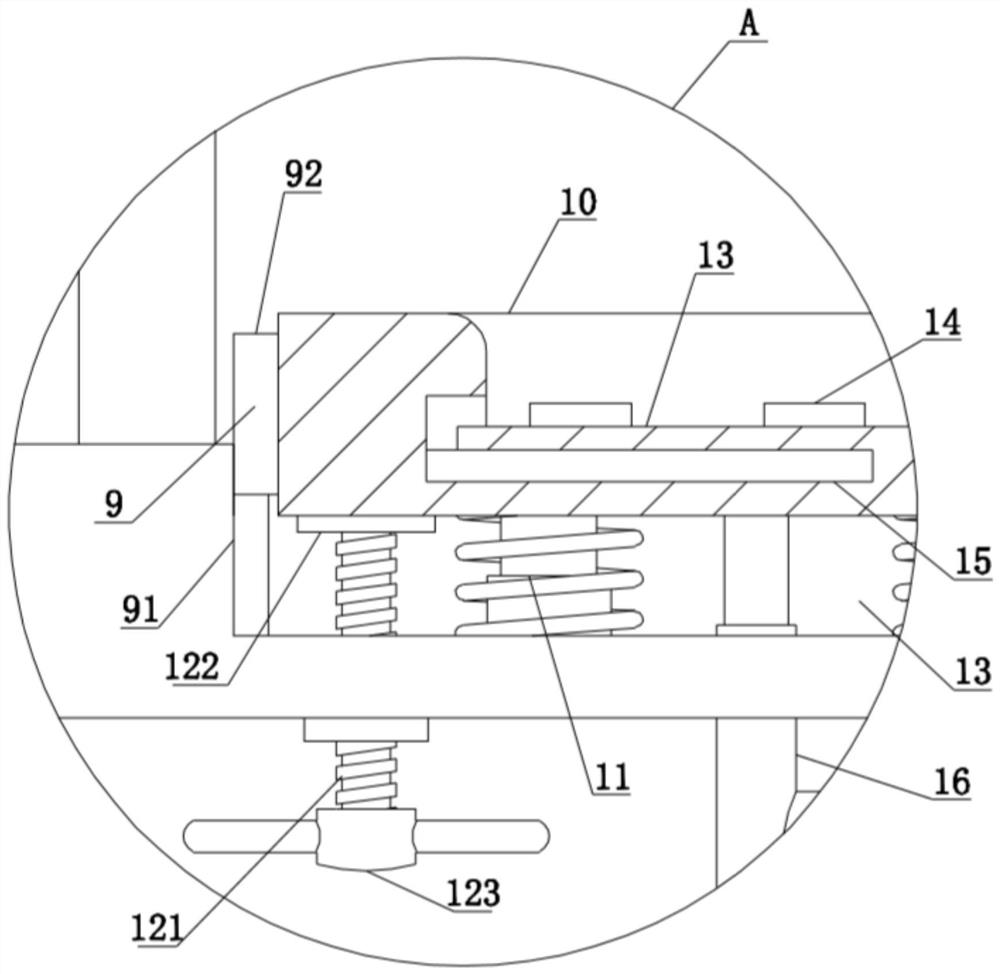

[0034] see Figure 1-Figure 3 , a hydraulic press, comprising a body 1, the upper end of the body 1 is fixedly connected with a base 2, both sides of the upper end of the base 2 are fixedly connected with fixed columns 3, and the upper end of the fixed column 3 is fixedly connected with a top plate 4 , both sides between the base 2 and the top plate 4 are fixedly connected with a guide shaft 24, and the guide shaft 24 runs through the press plate 6 and is slidingly connected with it, and when the hydraulic cylinder 5 pushes the press plate 6 to move, it runs through the press plate 6 for two The guide shaft 24 on the side can make the push plate move up and down in a straight line, making the push plate move more stably. The upper end of the top plate 4 is fixedly connected with a hydraulic cylinder 5, and the end of the telescopic shaft at the lower end of the hydraulic cylinder 5 runs through the top plate 4 and is fixed. A pressing plate 6 is connected, the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com