Auxiliary removal device for burr margin blank based on mud blank stamping mechanism

A stamping mechanism and auxiliary technology, applied in the field of mud billet manufacturing, can solve problems affecting product quality, deformation of the top section of the mud cylinder shape, and lack of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

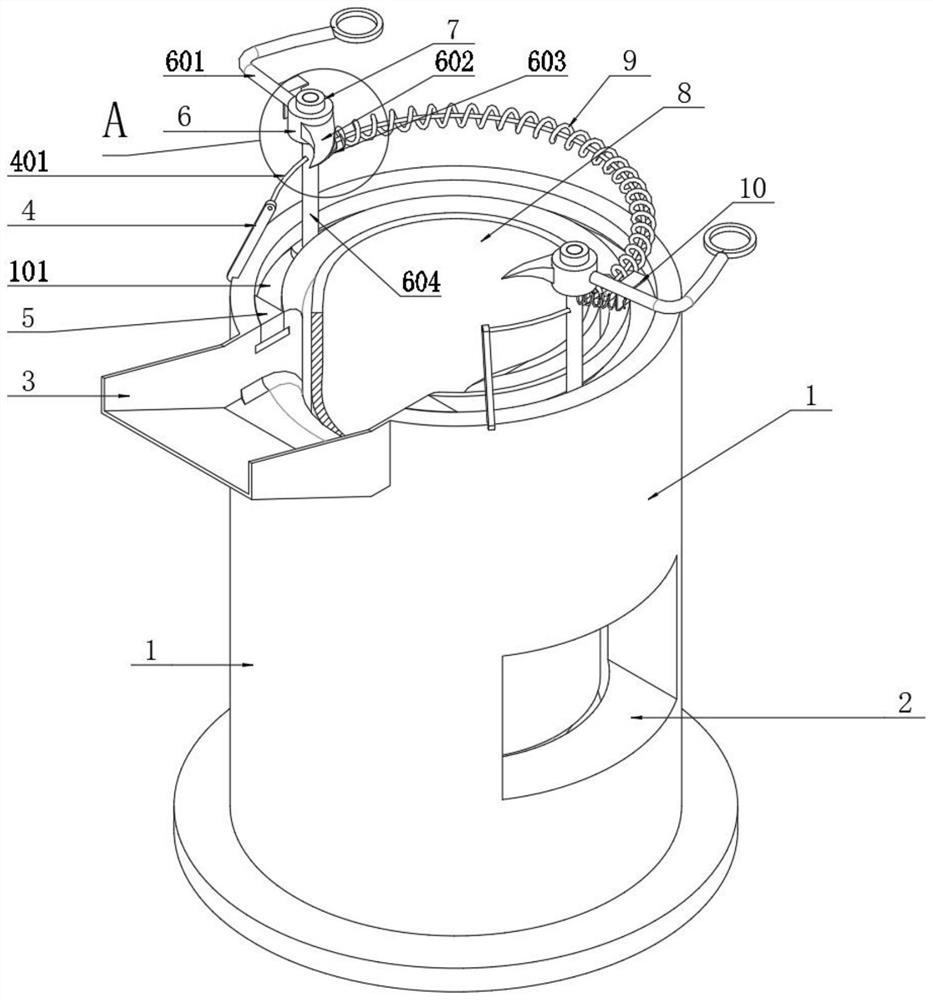

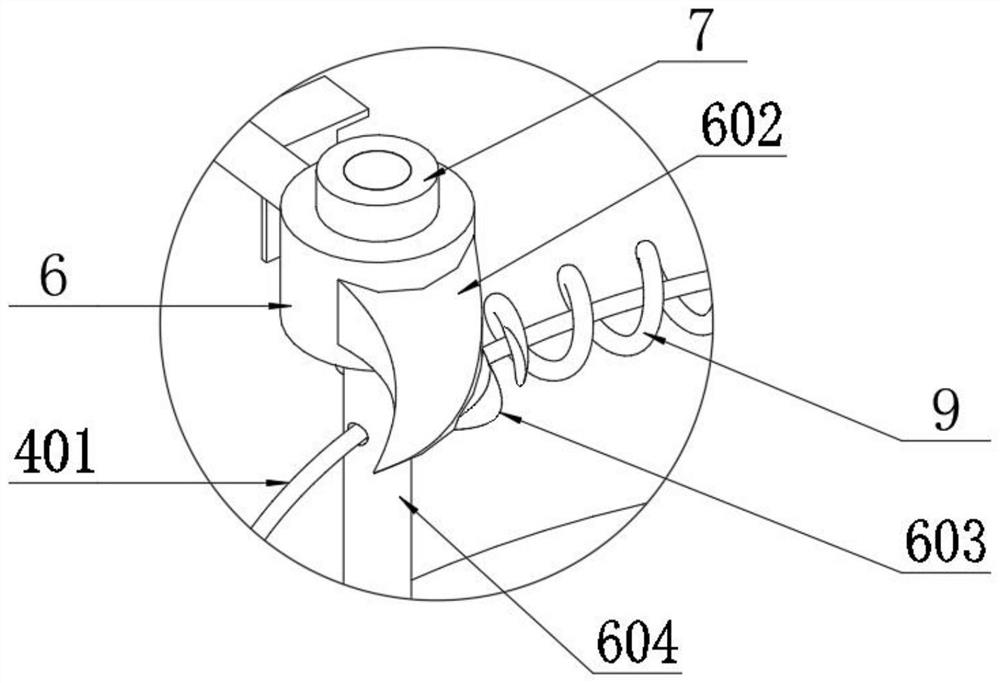

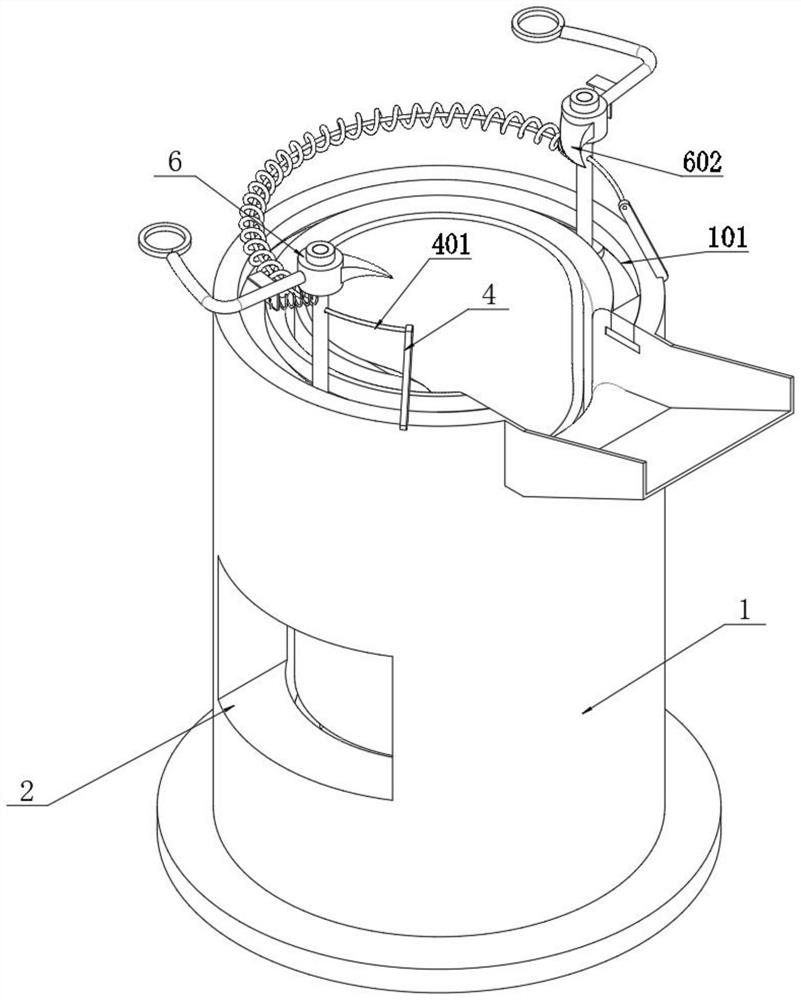

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides an auxiliary blank removal device based on a mud blank stamping mechanism, including a seat tube 1 and a stopper 5. The seat tube 1 is a column-type cavity structure, and a square opening is opened inward on both sides of the bottom. The notch 2 of the pattern, because a cylindrical mold 8 is vertically inserted in the circular cylinder cavity of the seat tube 1, this cylinder mold 8 can move up and down in the seat tube 1, the setting of the notch 2 It is used to prevent negative pressure in the inner cavity of the seat tube 1, and to prevent the tube mold 8, which is inserted into the inner cavity and slides up and down, from being seated when it is subjected to the downward extrusion of the die head of the existing extrusion equipment. Negative pressure in the bottom cavity of the cylinder 1 causes an explosion, which improves the rationality of the structure, and an annular bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com