Pipe orifice whole-orifice mold of automobile heat exchange system and mold release method thereof

A technology of heat exchange system and nozzle, which is applied in the field of nozzle integral mold and demoulding of automobile heat exchange system, which can solve the problems of increasing water cooling, unstable deformation, increased production and maintenance costs, etc., to ensure quality , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

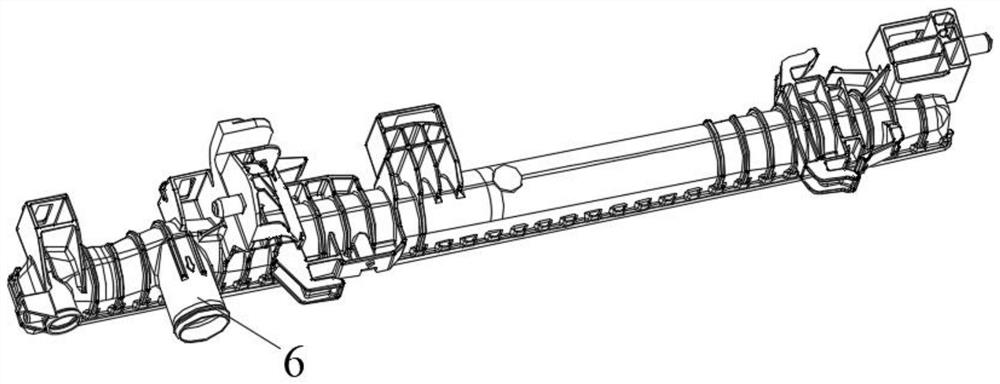

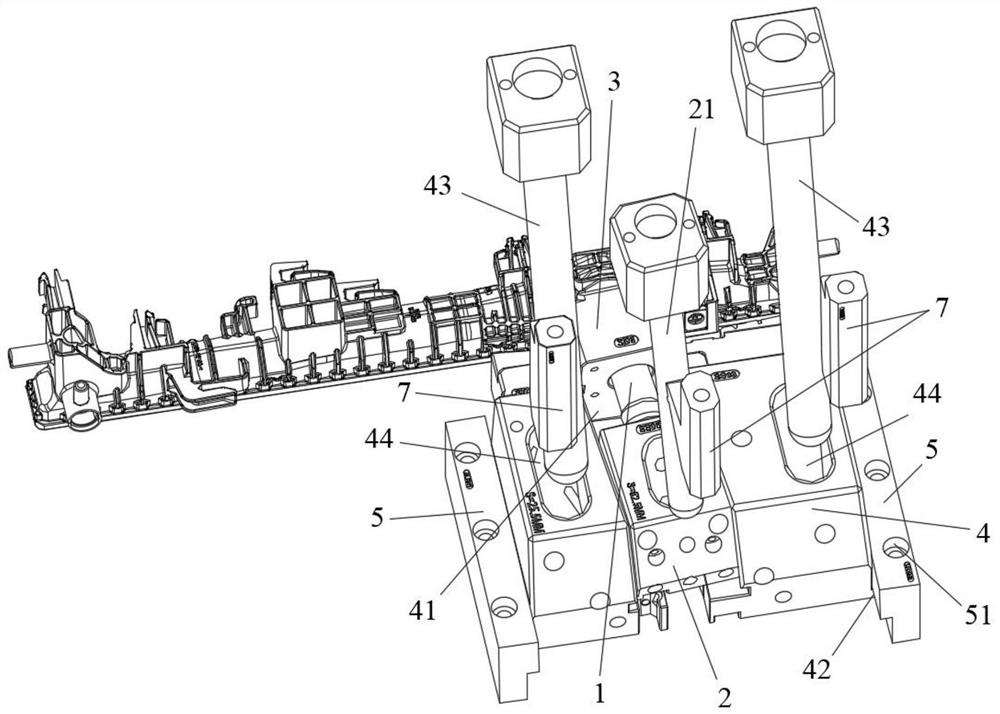

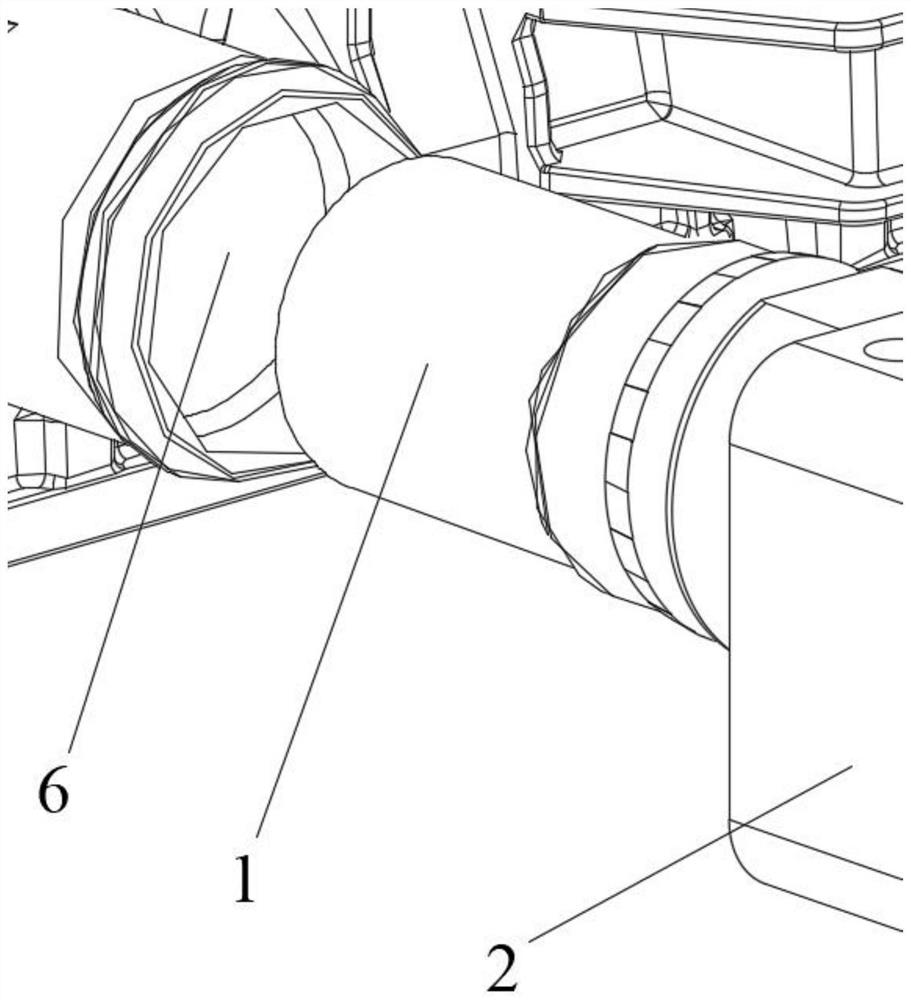

[0036] like Figure 1-3 As shown, a nozzle integral mold for an automobile heat exchange system includes a tube core insert 1, a small row seat 2, a nozzle insert 3, a large row seat 4, two beading bars 5 and a plurality of stoppers Block 7, the tube core insert 1 is connected with the small row seat 2, the nozzle insert 3 is connected with the large row seat 4, the middle part of the large row seat 4 is provided with a first guide groove 41, and the small row seat 2 is connected with the large row seat 4. Sliding connection between the first guide grooves 41, the small row position guide post 21 on the small row seat 2 cooperates with the second guide groove 22 on the small row seat 2, and the two beadings 5 are symmetrically arranged on the large row seat 4 On both sides, two bezels 5 are slidingly connected with the card protrusions 42 on both sides of the large row seat 4, the die insert 1 is accommodated in the nozzle insert 3, and the large row seat 4 is provided with ...

Embodiment 2

[0047] like Figure 1-3 Shown, a kind of demoulding method of the pipe nozzle integral mold of embodiment 1 automobile heat exchange system, comprises the steps:

[0048] S1. Injection molding the nozzle 6 of the car exchange system through an injection molding process;

[0049] S2, cooling liquid is set on the outer surface of the nozzle insert 3 to accelerate the cooling of the nozzle 6; liquid to accelerate cooling;

[0050] S3, move the limit block 7 that cooperates with the second guide groove 22; in the process of injection molding, one end of the limit block 7 is inserted into the large row seat 4 to prevent the small row seat 2 from sliding backwards, which acts as a mechanical lock Dead working effect, after the injection molding is completed, the limit block 7 is moved upwards, so that the end of the limit block 7 is separated from the large row seat 4, so as to move the small row seat 2;

[0051] S4. Drive the small row seat 2 to move through the small row guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com