Molding device and molding method for mask earbands

A molding method and earband technology, applied in the field of masks, can solve problems such as difficult maintenance, high equipment investment cost, and poor product quality uniformity, and achieve the effects of improving production efficiency, less time required for molding, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

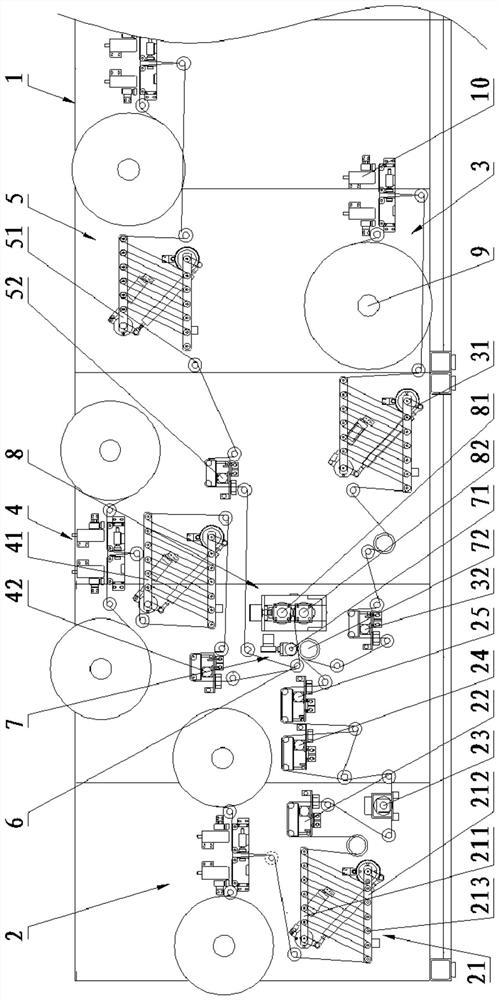

[0060] The forming device of the earband of the mask includes a frame 1 and an earband forming mechanism 2 arranged on the frame 1, an outer layer conveying mechanism 3, a middle layer conveying mechanism 4, an inner layer conveying mechanism 5, a composite roller 6, a pressing machine 7, side sealing machine 8, multiple air expansion shafts 9 and a splicing machine 10;

[0061] The earband forming mechanism 2 includes a first stocker 21, a first deviation corrector 22, and a divider 23 arranged in an assembly line, and a second deviation corrector 24 and a third deviation corrector 25 respectively arranged in an assembly line with the divider 23 ;

[0062] The outer layer conveying mechanism 3 includes a second stocker 31 and a fourth deviation corrector 32 arranged in an assembly line;

[0063] The middle layer conveying mechanism 4 includes a third stocker 41 and a fifth deviation corrector 42 arranged in an assembly line;

[0064] The inner layer conveying mechanism 5 in...

Embodiment 2

[0075] The molding method of mask earband specifically comprises the following steps:

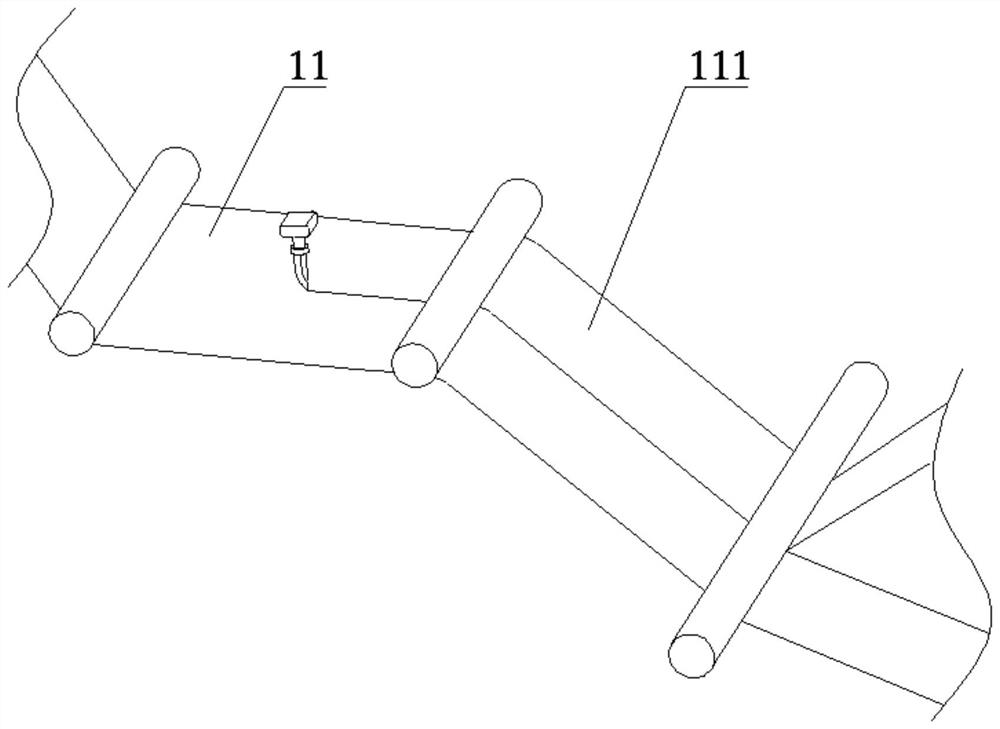

[0076] Step 1, the hanging ear material 11 is transported to the dividing machine 23 through the first stocker 21 and the first deviation correcting device 22 in sequence, and the hanging ear material 11 is cut into two ear straps 111 along the center line by the dividing machine 23, and the two ear straps The belt 111 is transported to the pressing machine 7 through the second deviation corrector 24 and the third deviation corrector 25 respectively;

[0077] Step 2, the outer layer material is sequentially transported to the press machine 7 through the material receiving machine 10, the second stocker 31 and the fourth deviation correcting device 32;

[0078] Step 3, the middle layer material and the inner layer material are transported to the fifth deviation corrector 42 and the sixth deviation corrector 52 through the third stocker 41 and the fourth stocker 51 respectively, and the fifth...

Embodiment 3

[0082] The molding method of mask earband specifically comprises the following steps:

[0083] Step 1. After the rolled lug material 11 is uncoiled by the inflatable shaft 9, it is sequentially transported to the splitter 23 through the splicer 10, the first stocker 21 and the first deviation corrector 22, and the lug material 11 is passed through the splitter. 23 cut into two ear straps 111 along the center line, and the two ear straps 111 are transported to the pressing machine 7 through the second deviation corrector 24 and the third deviation corrector 25 respectively;

[0084] Step 2. After the coiled outer layer material is uncoiled by the inflatable shaft 9, it is sequentially transported to the pressing machine 7 through the material receiving machine 10, the second material storage device 31 and the fourth deviation correcting device 32;

[0085] Step 3: After the coiled middle layer material and the coiled inner layer material are respectively uncoiled by an inflatab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com