Pile tip soil reinforcement system

A soil reinforcement and pile end technology, applied in soil protection, construction, geothermal power generation, etc., can solve problems such as insufficient bearing capacity, improve the consolidation coefficient, improve mechanical properties, and improve the bearing capacity of pile ends and lateral friction. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

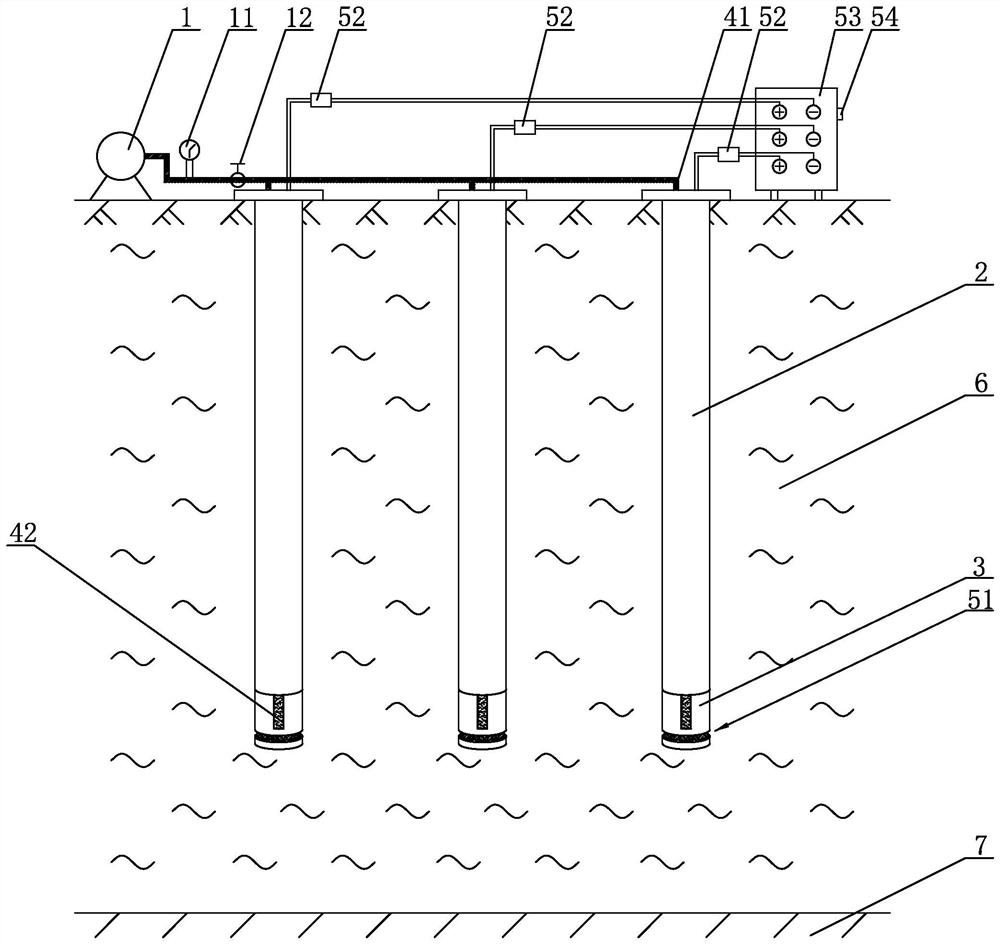

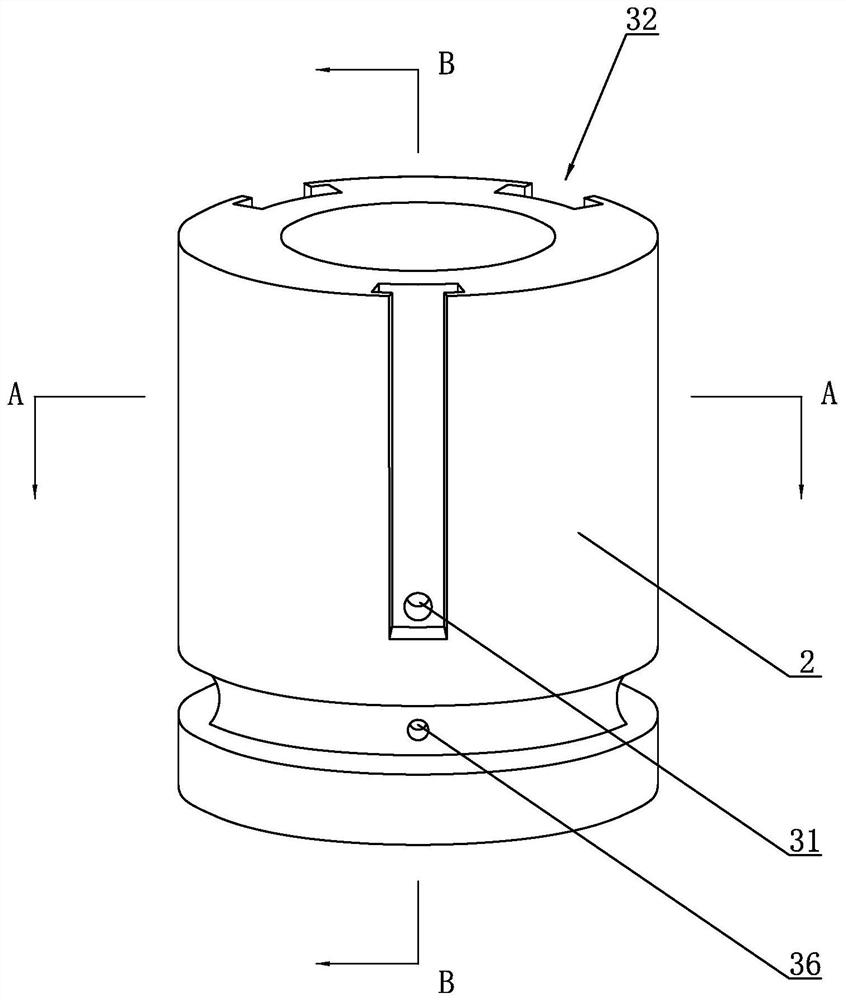

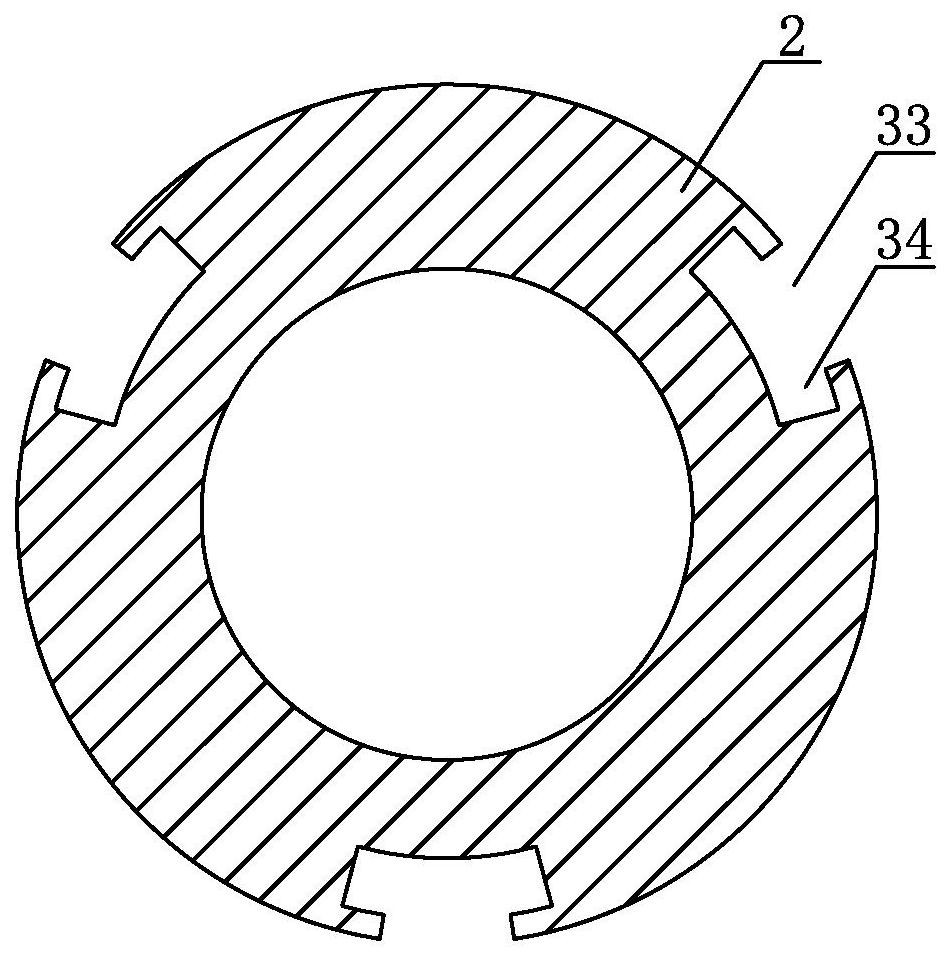

[0027] The pile end soil reinforcement system of embodiment 1, such as figure 1 As shown, it includes a vacuum pump 1 and a plurality of reinforcement units, each reinforcement unit includes an upright prefabricated pipe pile 2, a pile head 3, a drainage unit, a heating unit 51 and a temperature control unit 52, and the pile head 3 is fixed Connected to the bottom of the prefabricated pipe pile 2, each drainage unit includes a pipeline 41 and three drainage boards 42, the three drainage boards 42 are arranged on the pile head 3, one end of the pipeline 41 is connected with the vacuum pump 1, and the vacuum pump 1 A vacuum gauge 11 and a valve 12 are installed on the connecting pipeline with the pipeline 41. The other end of the pipeline 41 passes through the inner cavity of the prefabricated pipe pile 2 and communicates with three drainage boards 42. The heating unit 51 is arranged on the outside of the pile head 3 , the temperature of the heating unit 51 is controlled by a temp...

Embodiment 2

[0030] The pile tip soil reinforcement system of embodiment 2 differs from embodiment 1 in that in embodiment 2, such as Figure 6 As shown, each drainage board 42 includes a core board 44 and a filter membrane 45 coated on the periphery of the core board 44. In this embodiment, the core board 44 is cut from a plastic drainage board in the prior art, and the filter membrane 45 is a long fiber The hot-rolled non-woven filter membrane 45 is communicated with the cavity surrounded by the filter membrane 45 by the diversion hose 43 .

[0031] When the pile tip soil reinforcement system of Examples 1 and 2 is applied to the reinforcement of the prefabricated pile foundation of the deep soft soil foundation 6, before the construction of the pile foundation, first disconnect the connection between the pipeline 41 and the vacuum pump 1 and the resistance heating ring 55 and the temperature control unit. The connection of unit 52, during construction, press each prefabricated pipe pile...

Embodiment 3

[0033] The difference between the pile end soil reinforcement system of Embodiment 3 and Embodiment 2 is that in Embodiment 3, the prefabricated pipe pile 2 is replaced by a bamboo pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com