Construction method of prefabricated superposed type underground comprehensive pipe rack

A technology of integrated pipe gallery and construction method, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of inconvenient transportation, large volume of prefabricated parts of pipe gallery, and low installation and construction efficiency, and achieve convenient transportation and low weight. Lightweight and good load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

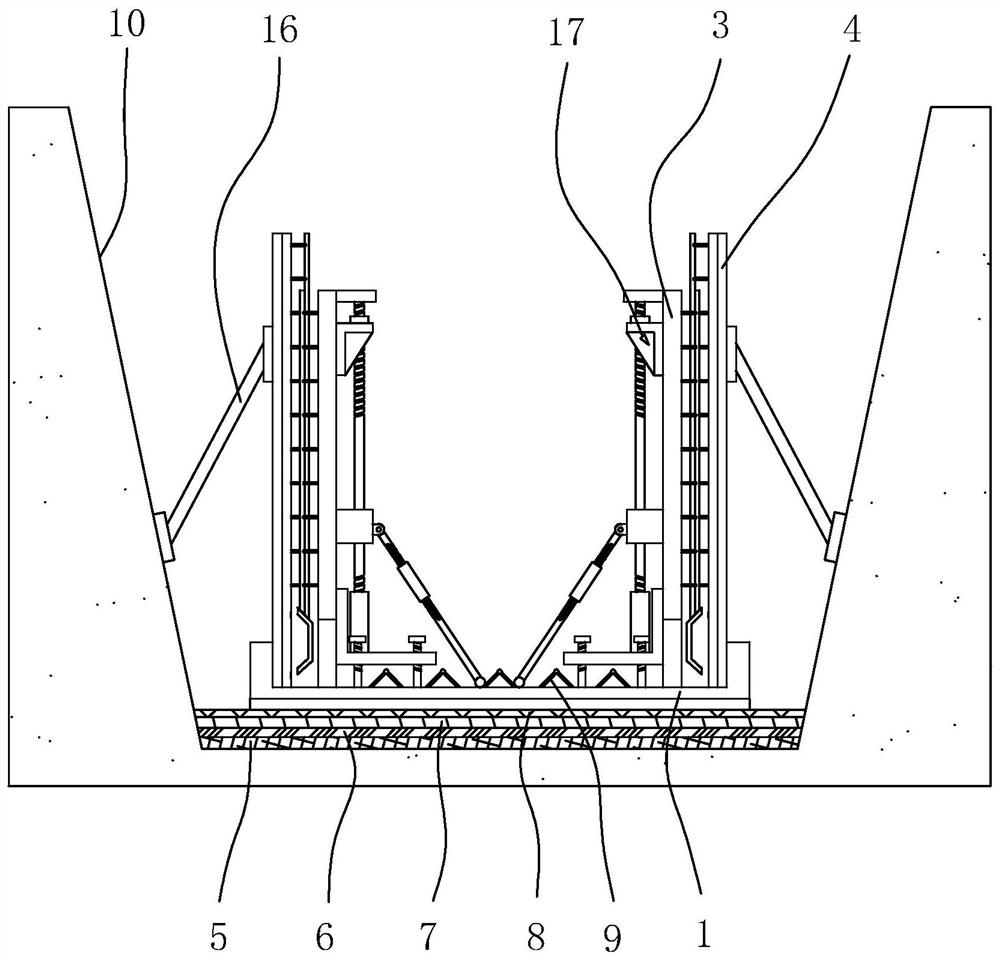

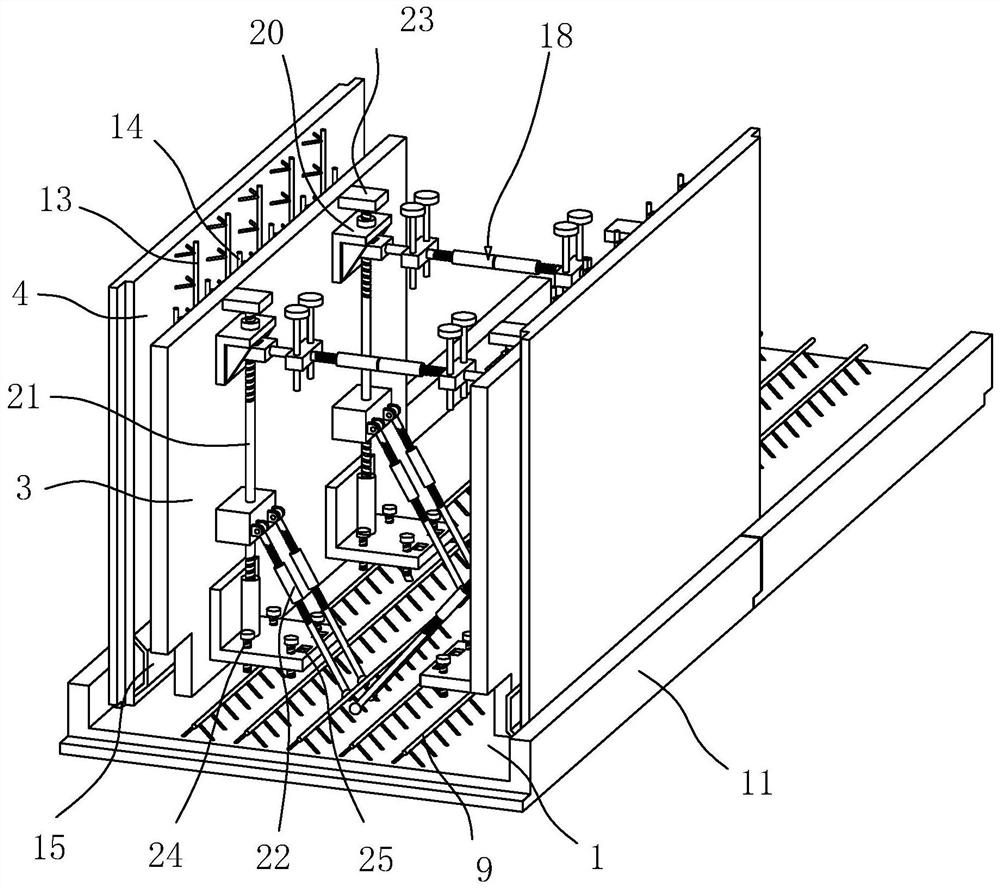

[0058] The following is attached Figure 1-11 The application is described in further detail.

[0059] The construction method of the comprehensive pipe gallery in the prior art includes construction preparation (including the production of the prefabricated parts of the pipe gallery and the transportation of the prefabricated pipe sections), excavation of the foundation pit, and the assembly and construction of the prefabricated parts of the pipe gallery. In this construction method, the prefabricated part of the pipe gallery is a tubular structure, and the volume is large, the transportation is inconvenient, and the installation and construction efficiency is low.

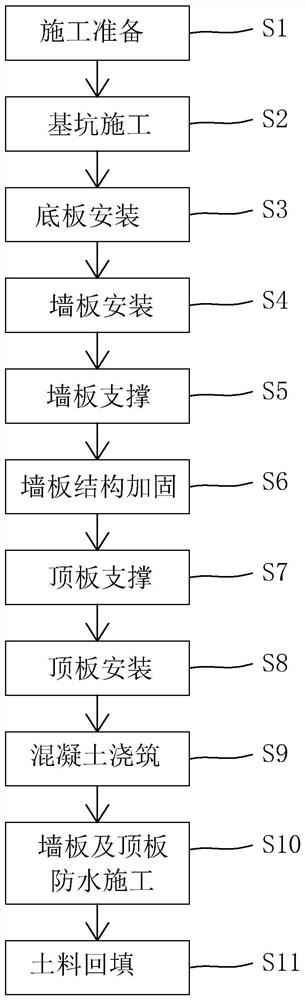

[0060] refer to figure 1 , the embodiment of the present application discloses a construction method of a prefabricated superimposed underground comprehensive pipe gallery, which mainly includes S1 construction preparation, S2 foundation pit construction, S3 floor installation, S4 wall panel installation, S5 wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com