Electromagnetic valve

A solenoid valve and solenoid coil technology, applied in the field of solenoid valves, can solve the problems of difficulty in increasing the lift of the plunger and the lift of the spool and valve wear, so as to increase the flow rate, suppress the wear of the valve, and keep the pressure rising when the valve is opened. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

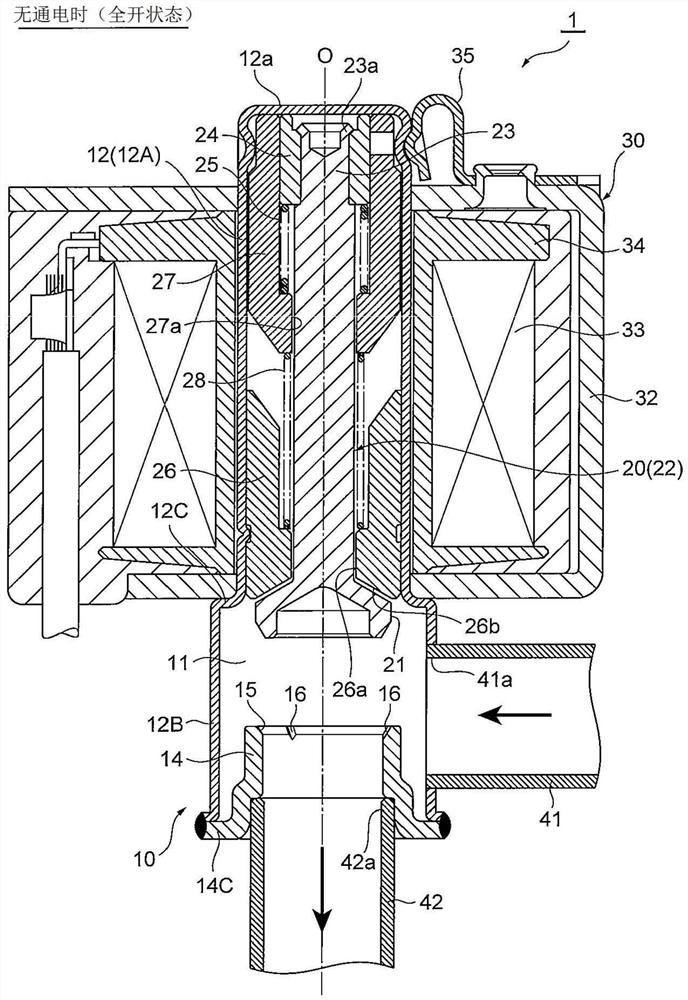

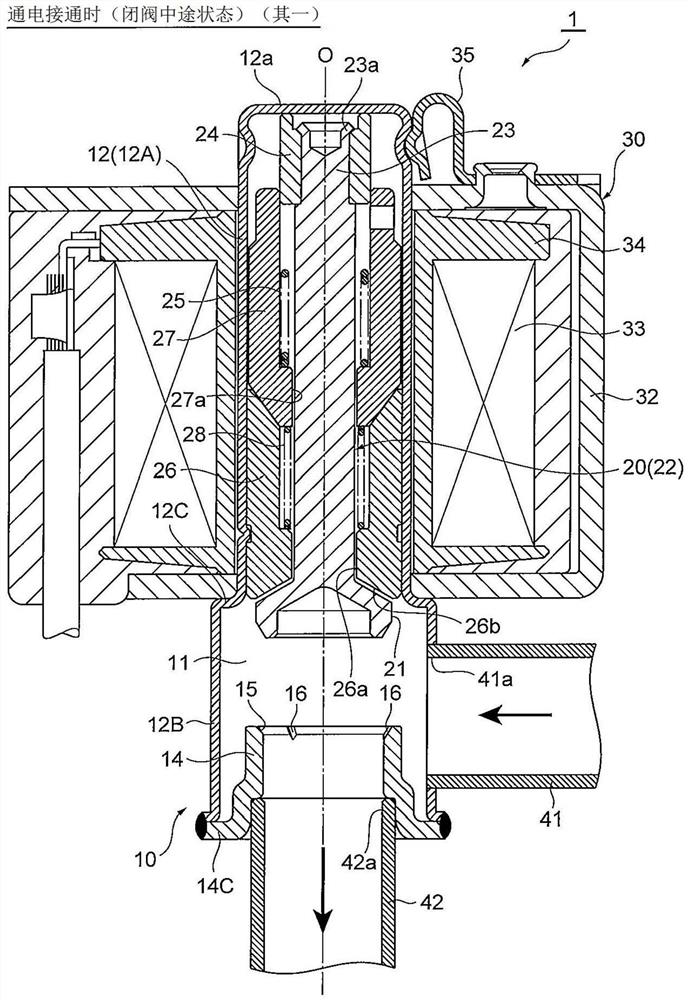

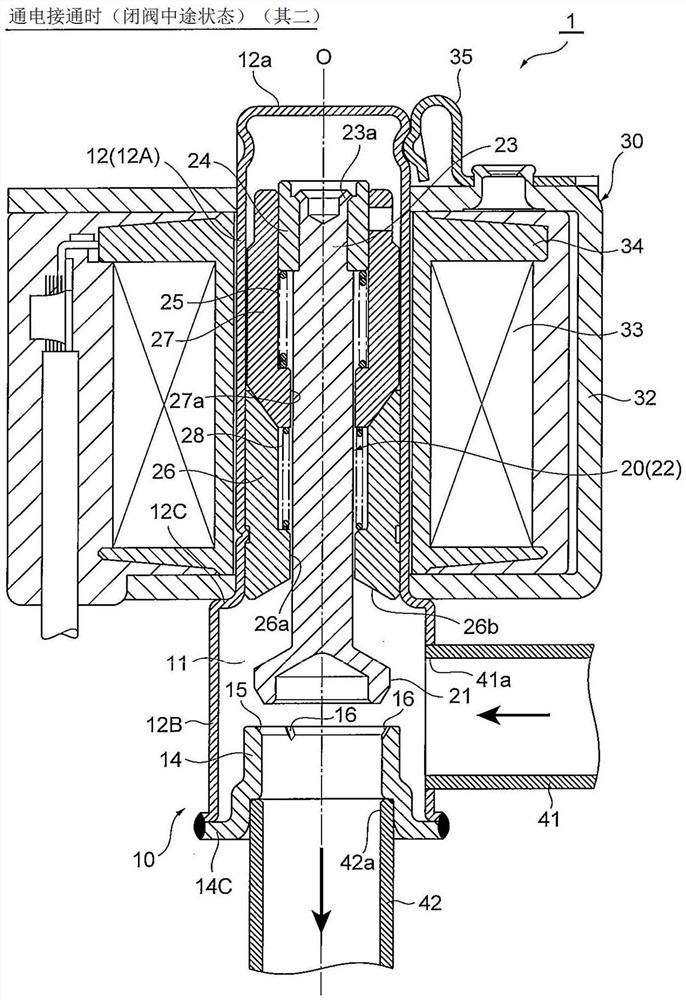

[0068] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described.

[0069] Figure 1 ~ Figure 4 It is a longitudinal sectional view showing one embodiment of the electromagnetic valve of the present invention, figure 1 Indicates when there is no power supply (full open state), figure 2 and image 3 Indicates that when the power is turned on (the halfway state of closing the valve), Figure 4 Indicates when the power is on (closed valve state).

[0070] In addition, in this specification, expressions indicating positions and directions such as up, down, left and right are for the convenience of referring to the drawings to avoid complicated descriptions, and do not necessarily refer to positions and directions in actual use.

[0071] Also, in each figure, gaps formed between components, isolation distances between components, and the like may be drawn larger or smaller than the size of each component for easier understanding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com