Flow equalization device used in pipeline

A technology of pipes and equalizing holes, which is applied in the direction of pipe components, fluid flow, pipes/pipe joints/fittings, etc., which can solve the problems of large water head loss, avoid or reduce vortices, and reduce the pressure loss of water body delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

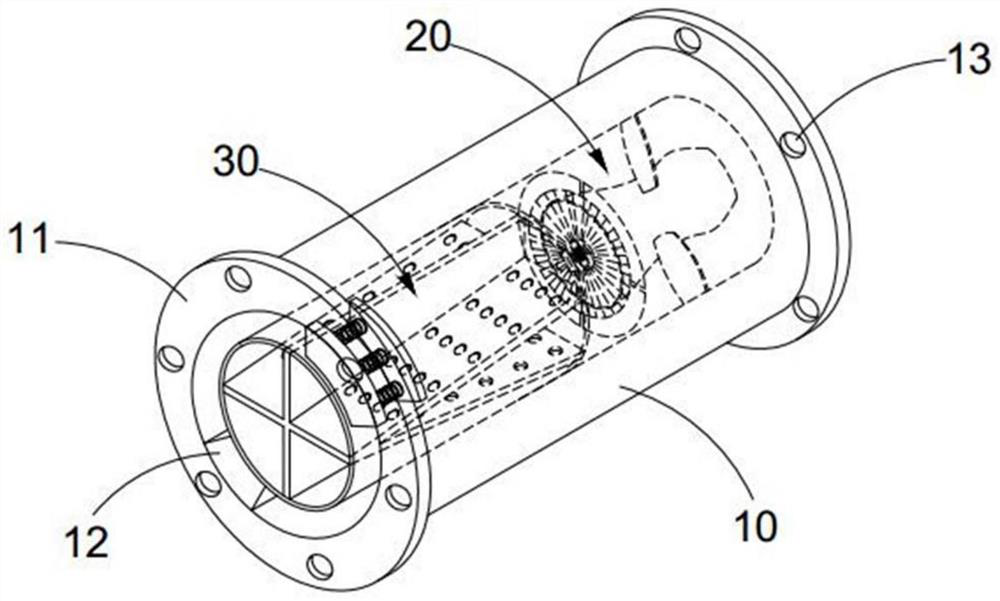

[0030] see Figure 2-7As shown, the flow equalization device used in the pipeline includes:

[0031] The first pipe body 10 is coaxially connected with the second pipe body 31 inside the first pipe body 10 . The water inlet end of the second pipe body 31 is provided with a first flow equalization assembly 30 , and the water outlet end is provided with a second flow equalization assembly 20 .

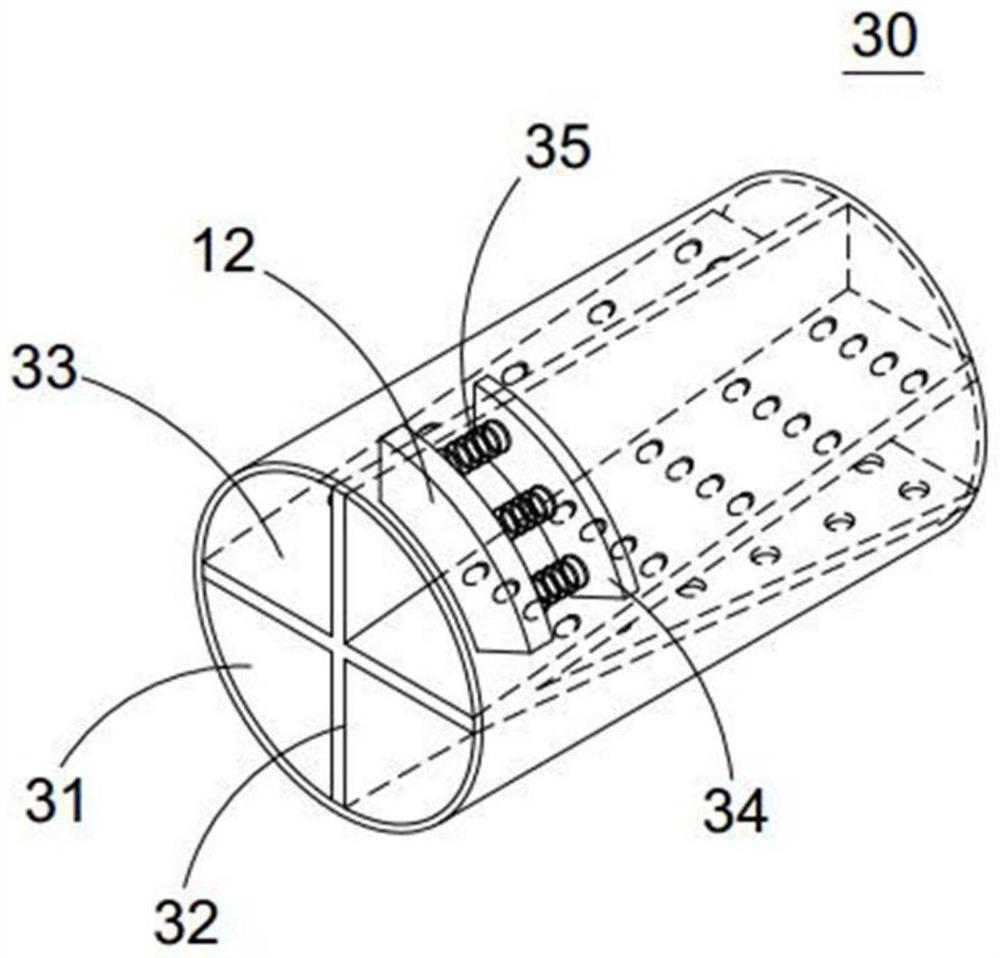

[0032] The inner walls at both ends of the first pipe body 10 are provided with a first connecting plate 12, and the two ends of the second pipe body 12 are provided with a second connecting plate 34 corresponding to the position of the first connecting plate 12, and the first connecting plate 12 is connected to the second connecting plate 12. The plates 34 are connected by elastic members 35;

[0033] Wherein, the first flow equalizing assembly 30 includes a first splitter plate 32 and a second splitter plate 33 arranged vertically in the second pipe body 31, the second splitter plate ...

Embodiment 2

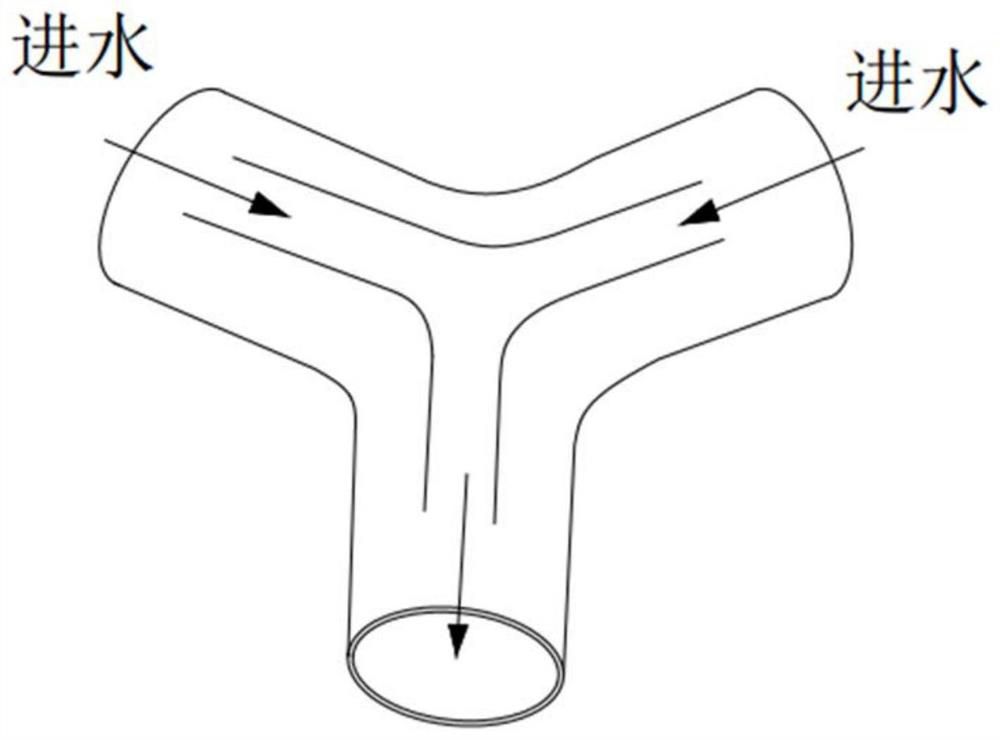

[0044] When the device of the present invention is actually used, it is installed on the water outlet end of the multi-way pipe, specifically connected by a flange, and the necessary sealing treatment is performed to prevent the leakage of the conveying liquid, and the multi-way pipe body pumps the water body under the action of the pump body Entering the main pipe, the device of the present invention performs flow equalization treatment through the device of the present invention during the multi-way pipe multi-stream fluid entering the main pipe. The multi-stream fluid first passes through the first flow equalization assembly 30, and most of the fluid entering the first pipe body 10 is in the second Flowing in the pipe body 31, a small part of the fluid flows from the inner wall of the first pipe body 10 and the outer wall of the second pipe body 31 to realize the stratified flow of the fluid. The distance between the water inlet of the second pipe body 31 and the water inlet...

Embodiment 3

[0046] The first flow equalization assembly 30 and the second flow equalization assembly 20 of the present invention are preferably installed in the same second pipe body 31, and can be installed in different sections of the second pipe body 31 when considering that the transmission path is too large; The elastic member 35 is preferably a rubber spring, which can effectively avoid the problem of metal spring corrosion and pollution of the transmission medium during long-term contact with water bodies. The second pipe body 31 is preferably a metal pipe fitting, but it needs to be sprayed with anti-corrosion and anti-fouling coatings on its inner and outer surfaces. Of course Rubber pipe fittings can also be used as the second pipe body 31. The thickness of the second pipe body 31 is not easy to be too large, and is generally controlled within 0.5-1.5 cm. In addition, the surface of the rotating part 24 can be provided with a guide vane 25 to improve the limit position. Fluid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com