Workpiece surface quality detection method and device and appearance machine

A detection method and workpiece surface technology, which is applied to the detection device of workpiece surface quality, detection of workpiece surface quality, and the field of appearance machine, which can solve the problems of large difference in gray scale value, increase of machine false alarms, and reduction of machine efficiency. , to achieve the effect of improving machine productivity, improving product yield, and reducing false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

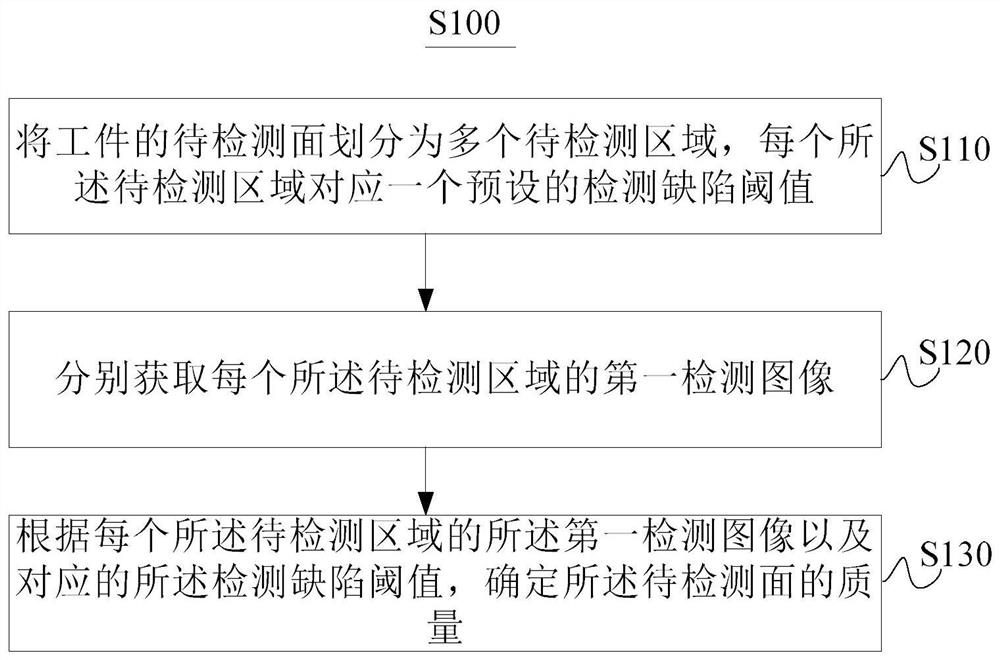

[0057] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

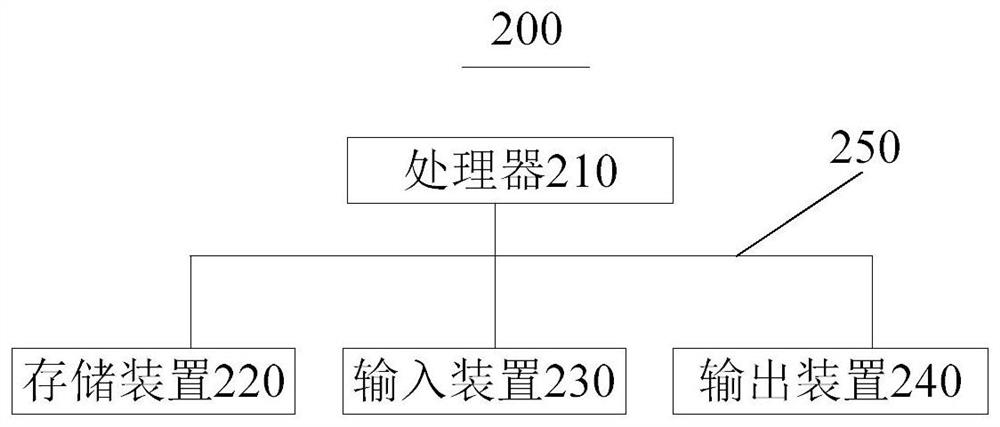

[0058] First, refer to figure 1 An example electronic device for implementing the detection device and detection method according to an embodiment of the present invention will be described.

[0059] Such as figure 1As shown, the electronic device 200 includes one or more processors 210, one or more storage devices 220, one or more input devices 230, one or more output devices 240, etc., these components are connected via a bus system 250 and / or other The form of the connecting mechanism interconnects. It should be noted that figure 1 The shown components and structure of the electronic device are exemplary rather than limiting, and the electronic device may also have other components and structures as required.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com