Atmospheric calibration method, atmospheric calibration device and atmospheric calibration system for oxygen sensor

A technology of an oxygen sensor and a calibration method, which is applied in the field of oxygen sensors and can solve the problems of time-consuming and labor-intensive atmospheric calibration methods of the oxygen sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

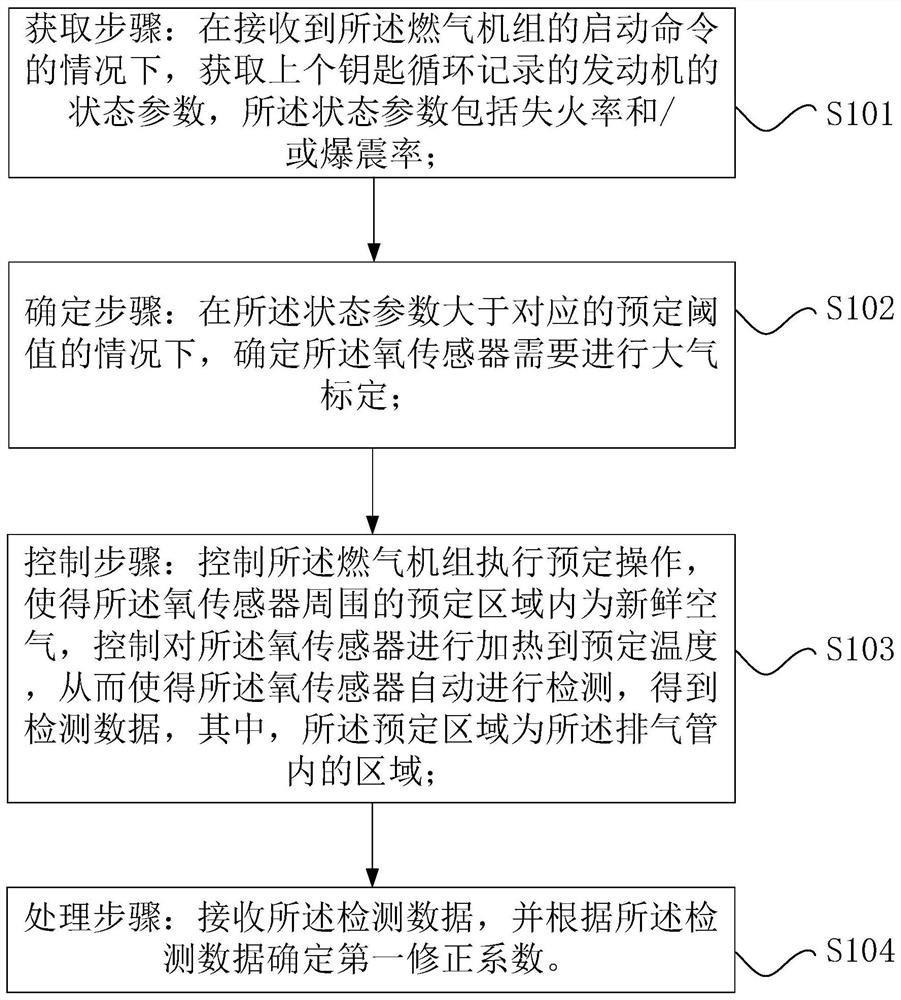

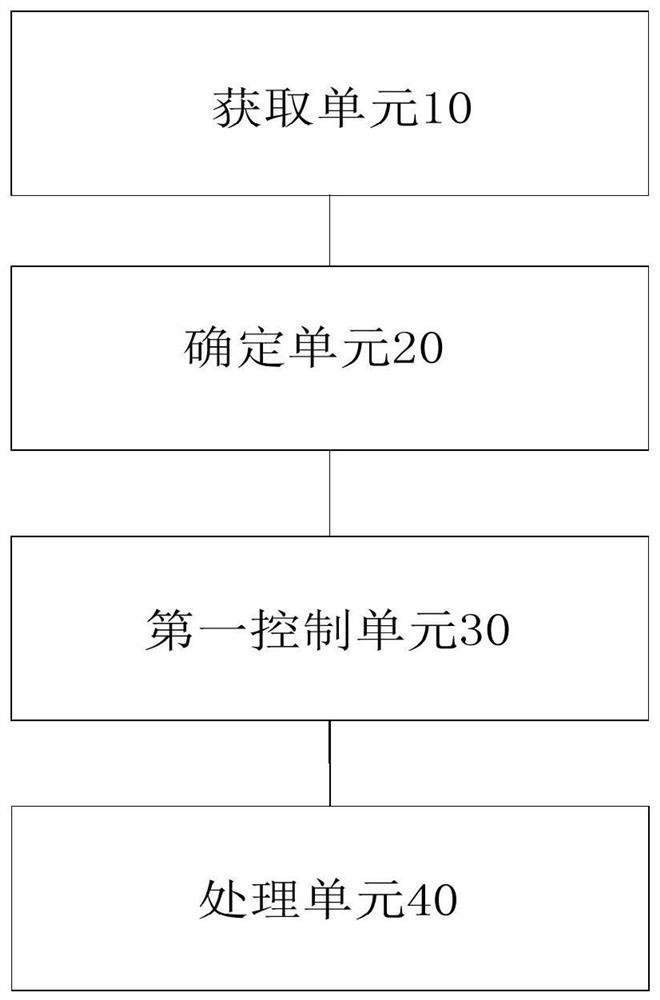

Method used

Image

Examples

Embodiment

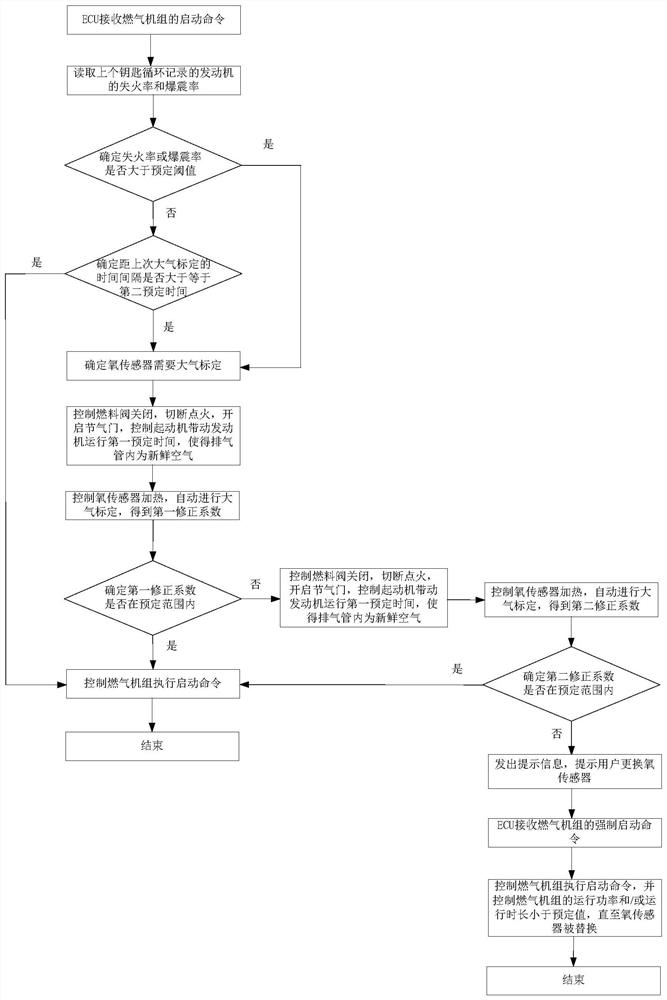

[0070]The atmospheric calibration system of this embodiment includes an atmospheric calibration device, an oxygen sensor and a gas-fired unit, the above-mentioned atmospheric calibration device is an electronic control unit ECU, and the above-mentioned gas-fired unit includes an exhaust pipe, an air pipeline, a gas pipeline, a mixing pipeline, an engine, A throttle valve and a fuel valve, wherein the oxygen sensor is located on the exhaust pipe, one end of the air pipeline is connected to the air inlet of the engine, one end of the gas pipeline is connected to the gas inlet of the engine, and the mixing pipeline One end of each is connected to the other end of the air pipeline and the other end of the gas pipeline, the engine includes a starter, the throttle valve is set on the mixing pipeline, and the fuel valve is set on the gas pipeline.

[0071] Such as image 3 As shown, the atmospheric calibration system performs the atmospheric calibration method including the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com