Method and system for checking performance of frequency response method transformer winding deformation online monitoring sensor

A technology for detecting sensors and sensors, which is applied to parts, instruments, and measuring devices of electrical measuring instruments, and can solve problems such as meeting application requirements, being unable to guarantee sensor performance parameters, and having no sensor performance inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the application. However, the present application can be implemented in many other ways different from those described here, and those skilled in the art can make similar promotions without violating the connotation of the present application. Therefore, the present application is not limited by the specific implementation disclosed below.

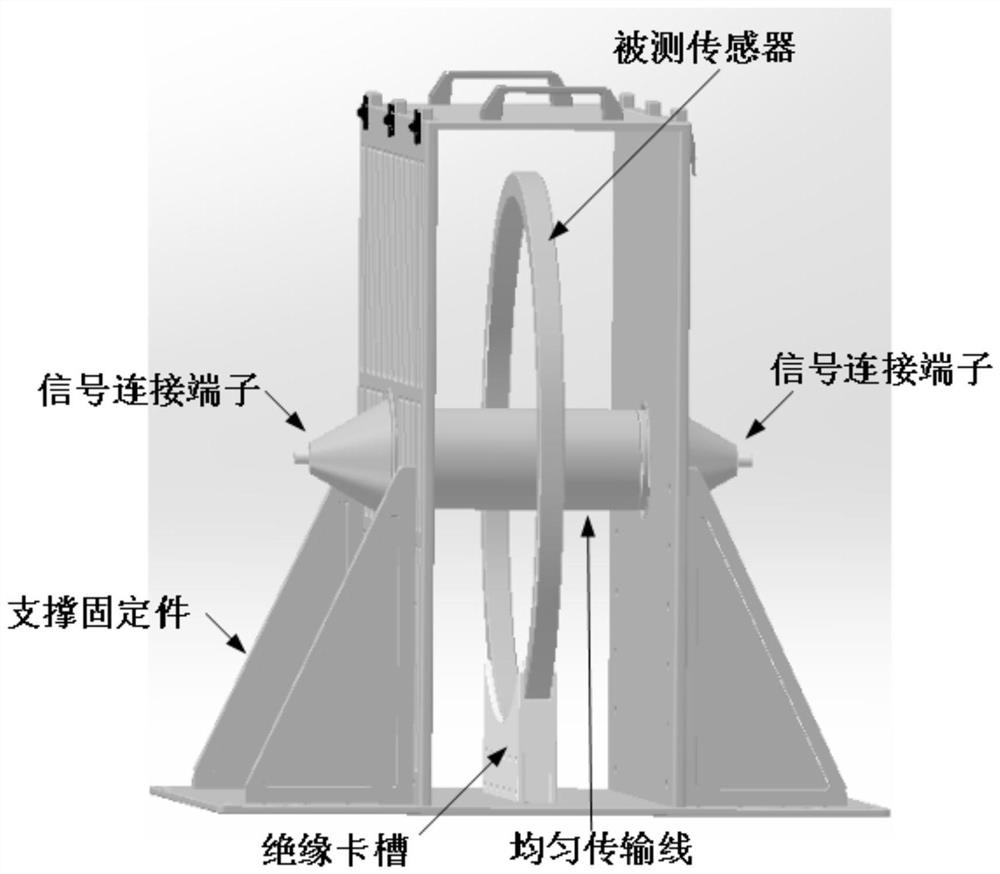

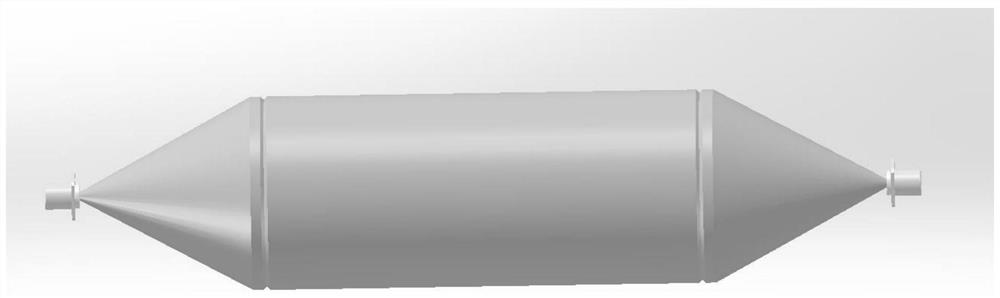

[0049] This application provides a coaxial matching fixture for detecting the deformation of the transformer winding by the frequency response method and monitoring the performance of the on-line sensor. Its structure is as follows figure 1 shown. A coaxial mating fixture consisting of a support fixture and a uniform transmission line.

[0050] The support fixture includes an upper cover plate, a lower support plate, and left and right support plates for supporting the measured sensor and a uniform transmission line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com