A simulation analysis method of engine hatch cover shaking based on air pressure load

An engine cover and air pressure technology, applied in the field of simulation analysis, can solve the problems of cost cost and time cost, and achieve the effect of improving accuracy and reducing time cost and cost cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will further explain and illustrate the engine compartment cover shake simulation analysis method based on air pressure loads in the present invention in conjunction with the accompanying drawings and specific embodiments, but the explanation and illustration do not constitute an improper limitation to the technical solution of the present invention .

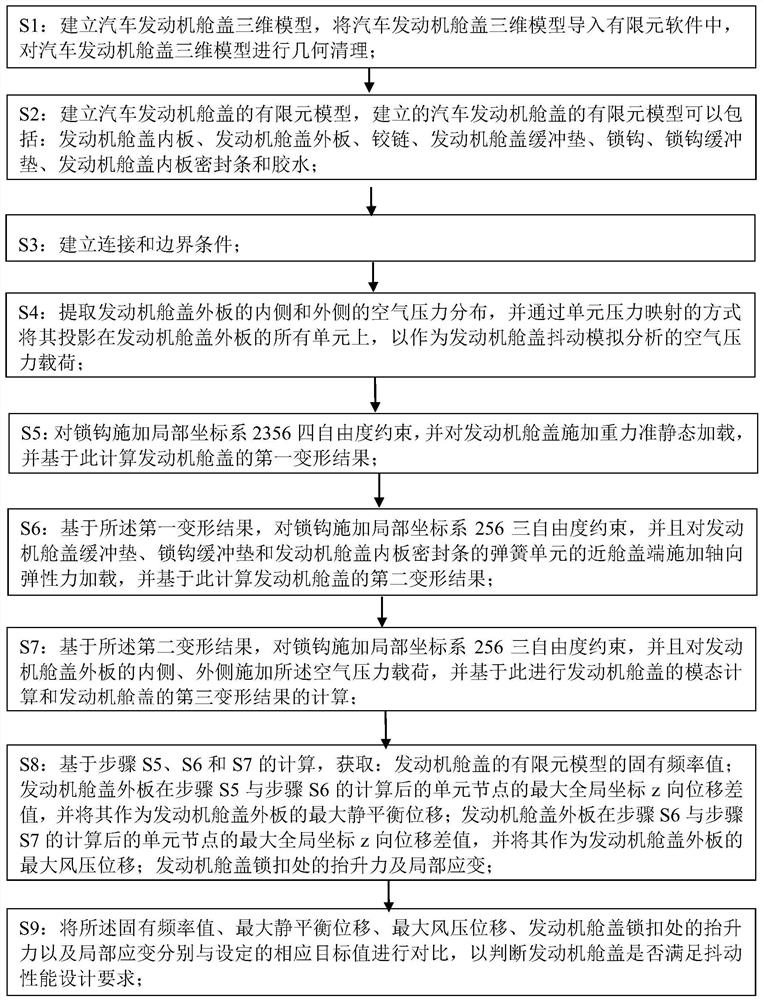

[0042] figure 1 It is a schematic flow chart of an embodiment of the method for simulating and analyzing vibration of the engine compartment cover based on the air pressure load according to the present invention.

[0043] Such as figure 1 As shown, the engine hatch shake simulation analysis method based on the air pressure load of the present invention can adopt the following steps:

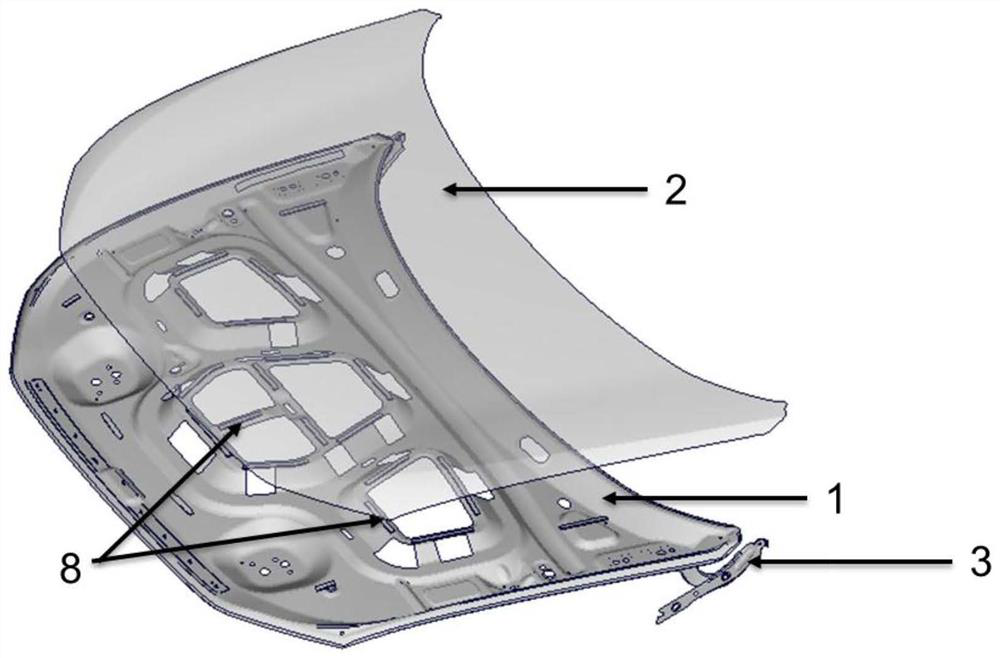

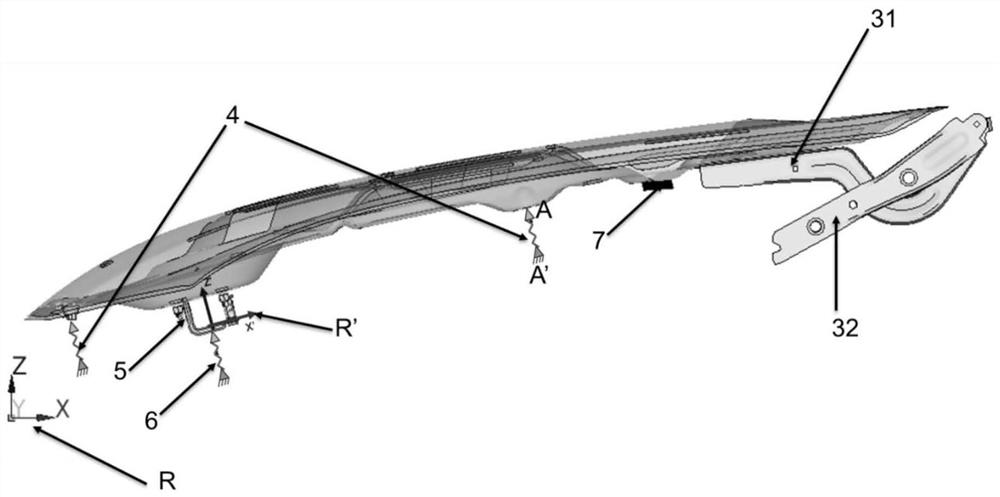

[0044] S1: Establish a three-dimensional model of the engine compartment cover, import the three-dimensional model of the engine compartment cover into the finite element software, and perform geometric cleaning on the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com