Photoelectric hybrid data transmission cable and Type-C data line

A data transmission, optoelectronic hybrid technology, applied in the field of data transmission, can solve the problems of poor anti-interference of metal transmission, inconvenience to carry around, large cable diameter, etc., to achieve the effect of good reliability, easy portability, and reduced cable diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

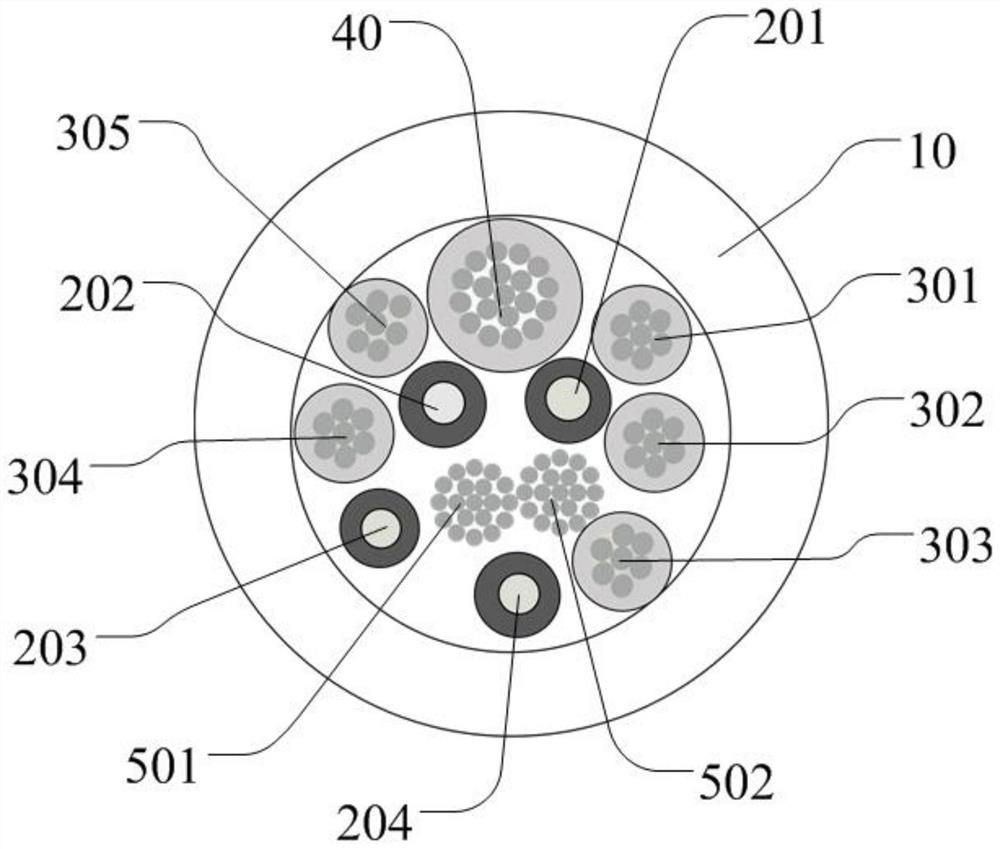

[0034] In this embodiment, a TB450 optical fiber is used, the outer diameter of the optical fiber is 0.45 mm, and the outer cladding wire diameter is 2.75±0.25 mm. The optical fiber adopts TB450 optical fiber with a large outer diameter, while the optical-electric hybrid data transmission cable has a small diameter, good reliability and easy to carry. The specific structure and dimensions of the photoelectric hybrid data transmission cable of this embodiment are shown in Table 1.

[0035] Table 1 Specific structure and size of the photoelectric hybrid data transmission cable in Example 1

[0036] Serial number name Material structure Size model Features 1 Outer layer TPU 2.75+ / -0.25mm Outside protection 2 First optical cable TB450 0.45mm Optical signal transmission 3 Second optical cable TB450 0.45mm Optical signal transmission 4 Third optical cable TB450 0.45mm Optical signal transmission 5 Fourth optical cable TB450 0.45mm Optical signal transmission 6 Power transmission cab...

Embodiment 2

[0038] In this embodiment, a TB450 optical fiber is used, the outer diameter of the optical fiber is 0.45 mm, and the outer cladding wire diameter is 3.25±0.25 mm. The optical fiber uses TB450 optical fiber, which has a large outer diameter and good reliability. The wire diameter of the photoelectric hybrid data transmission cable is 3.25±0.25mm, which is large and easy to produce. The specific structure and dimensions of the photoelectric hybrid data transmission cable of this embodiment are shown in Table 2.

[0039] Table 2 Specific structure and size of the photoelectric hybrid data transmission cable in Example 2

[0040] Serial number name Material structure Size model Features 1 Outer layer TPU3.25+ / -0.25 Outside protection 2 First optical cable TB450 0.45mm Optical signal transmission 3 Second optical cable TB450 0.45mm Optical signal transmission 4 Third optical cable TB450 0.45mm Optical signal transmission 5 Fourth optical cable TB450 0.45mm Optical signal transmis...

Embodiment 3

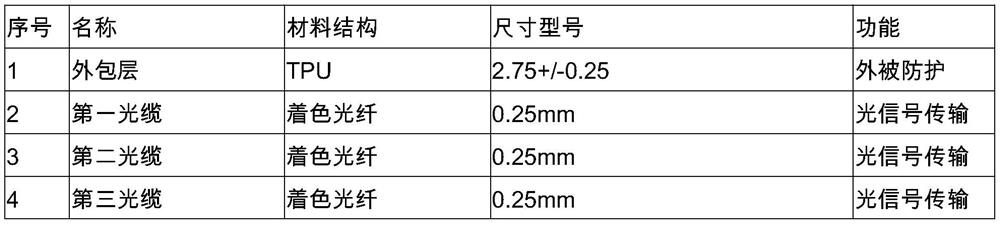

[0042] In this embodiment, an ordinary colored optical fiber is used, the outer diameter of the optical fiber is 0.25 mm, and the outer cladding wire diameter is 2.75±0.25 mm. The optical fiber adopts ordinary colored optical fiber with low cost. The specific structure and dimensions of the photoelectric hybrid data transmission cable of this embodiment are shown in Table 3.

[0043] Table 3 Specific structure and size of the photoelectric hybrid data transmission cable of the third embodiment

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com