Preparation method of bismuth telluride-based textured block thermoelectric material

A thermoelectric material, bismuth telluride-based technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, etc., can solve the problem of low thermoelectric figure of merit of materials, affecting material thermoelectric properties, and grain preferential orientation damage and other issues, to achieve the effects of good machining performance, lower production costs, good application prospects and industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

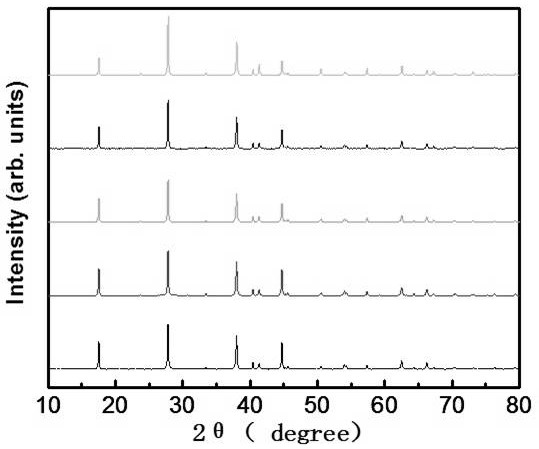

Image

Examples

Embodiment 1

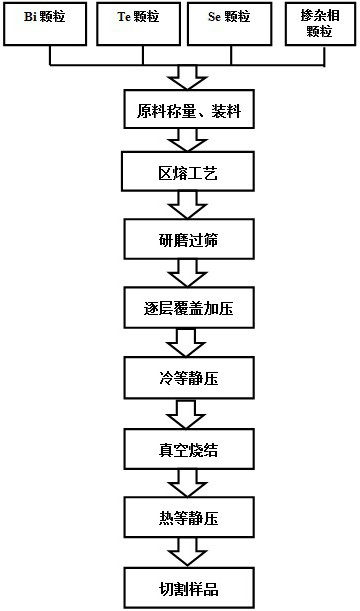

[0039] In this example, a bismuth telluride-based bulk thermoelectric material was prepared by combining zone melting process, layer-by-layer covering pressurization and vibration-assisted process, cold isostatic pressing process, vacuum sintering process and hot isostatic pressing process, as follows:

[0040] (1) The bismuth telluride alloy was prepared by the zone melting method, which was exactly the same as the process of preparing the bismuth telluride alloy by the zone melting method in the comparative example;

[0041] (2) Using the bismuth telluride alloy prepared in step (1) as the initial raw material, pulverize, grind, and sieve to obtain a powder material with a particle size in the range of 180-380um, and weigh an appropriate amount of the powder;

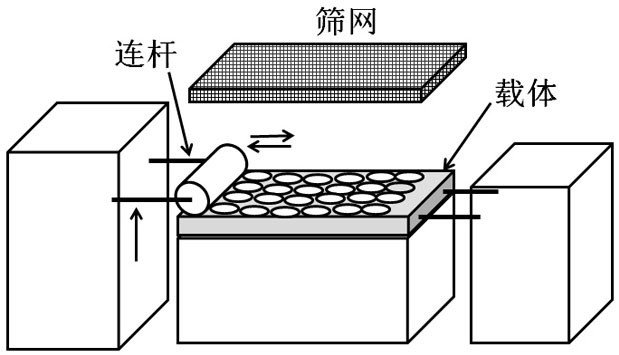

[0042] (3) Polish the surface of the carrier in the pressurized and vibration-assisted orientation device layer by layer, and attach a layer of epoxy glue with a thickness of 20um as the adhesive;

[0043] (4) Put the...

Embodiment 2

[0049] In this example, the bismuth telluride-based bulk thermoelectric material was prepared by combining zone melting process, layer-by-layer covering pressurization and vibration-assisted process, cold isostatic pressing process, vacuum sintering process and hot isostatic pressing process. Compared with the process of preparing a nearly completely dense and well-oriented bulk thermoelectric material in Example 1, the particle size of the powder material obtained by sieving only in step (2) is different, ranging from 120 to 180um. The other processes are the same as those in Example 1. 1, the process is exactly the same.

[0050] The nearly completely dense and well-oriented bulk thermoelectric material after HIP sintering was cut into strips of 2×2×9mm and discs of φ10×1.5mm, which were used to measure the electrical transport properties and thermal properties, respectively. transport properties.

Embodiment 3

[0052] In this embodiment, a bismuth telluride-based bulk thermoelectric material is prepared by combining zone melting process, layer-by-layer covering pressurization and vibration-assisted process, cold isostatic pressing process, vacuum sintering process and hot isostatic pressing process. Compared with the process of preparing a nearly completely dense and well-oriented bulk thermoelectric material in Example 1, the particle size of the powder material obtained by sieving in step (2) is different, ranging from 96 to 120um, and other processes Exactly the same process as in Example 1.

[0053] The nearly completely dense and well-oriented bulk thermoelectric material after HIP sintering was cut into strips of 2×2×9mm and discs of φ10×1.5mm, which were used to measure the electrical transport properties and thermal properties, respectively. transport properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap