Steamed stuffed bun wrapper, quick-frozen steamed stuffed bun and production process

A production process and technology for steamed buns, applied in the field of food processing, can solve problems such as affecting the appetite of consumers, cracking of quick-frozen steamed buns, and not looking good, and achieve the effects of uniform and tough internal tissue, prolonging the shelf life and reducing destruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

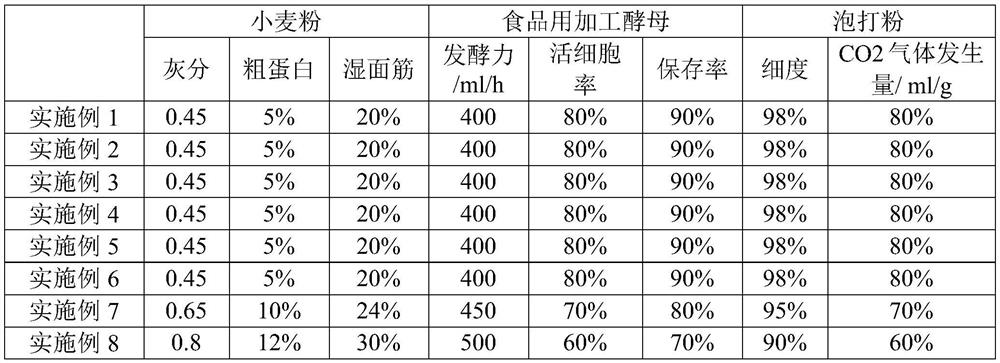

Examples

Embodiment 1

[0051] A kind of production technology of bun skin comprises the steps:

[0052] 1), 0.5kg soft white sugar and 0.3kg edible salt are dissolved in 17kg water, stir evenly, adopt 100 order sieves to filter;

[0053] 2) Dissolve 0.5kg of baking powder in the filtrate within 10s to obtain a mixed solution;

[0054] 3) Put 0.8kg of processed yeast for food into the mixture within 10s, mix evenly,

[0055] 4), add 32kg of wheat flour, stir evenly, ferment at 30°C for 25 minutes, roll the noodles, make skins, and obtain steamed stuffed bun skins.

Embodiment 2

[0057] A kind of production technology of bun skin comprises the steps:

[0058] 1), 1.2kg soft white sugar and 0.8kg edible salt are dissolved in 9kg water, stir evenly, adopt 100 order sieves to filter;

[0059] 2) Dissolve 0.1kg of baking powder in the filtrate within 10s to obtain a mixed solution;

[0060] 3) Put 0.1kg of processed yeast for food into the mixture within 10s, mix evenly,

[0061] 4), add 21kg of wheat flour, stir evenly, ferment at 30°C for 25 minutes, roll the noodles, and make skin to obtain steamed stuffed bun skin.

Embodiment 3

[0063] A kind of production technology of bun skin comprises the steps:

[0064] 1), 0.75kg soft white sugar and 0.5kg edible salt are dissolved in 14kg water, stir evenly, adopt 100 order sieves to filter;

[0065] 2) Dissolve 0.25kg of baking powder in the filtrate within 10s to obtain a mixed solution;

[0066] 3) Put 0.4kg of processed yeast for food into the mixture within 10s, mix evenly,

[0067] 4), add 25kg of wheat flour, stir evenly, ferment at 30°C for 25 minutes, roll the noodles, make skins, and obtain steamed stuffed bun skins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fermentation power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap