Atomization device capable of improving atomization effect and preventing liquid leakage

An atomization device and anti-leakage technology, which is applied in the treatment of atomizers, tobacco, etc., can solve the problems of affecting the experience, affecting the perception, and prone to spillage, so as to solve the problem of liquid leakage, uniform atomization and more Fully and enhance the effect of atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

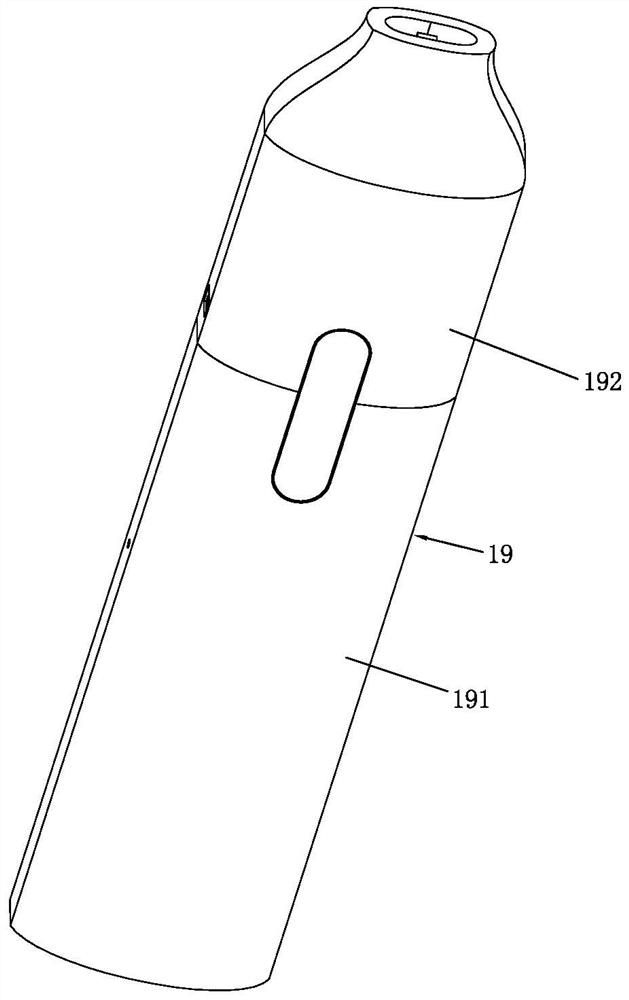

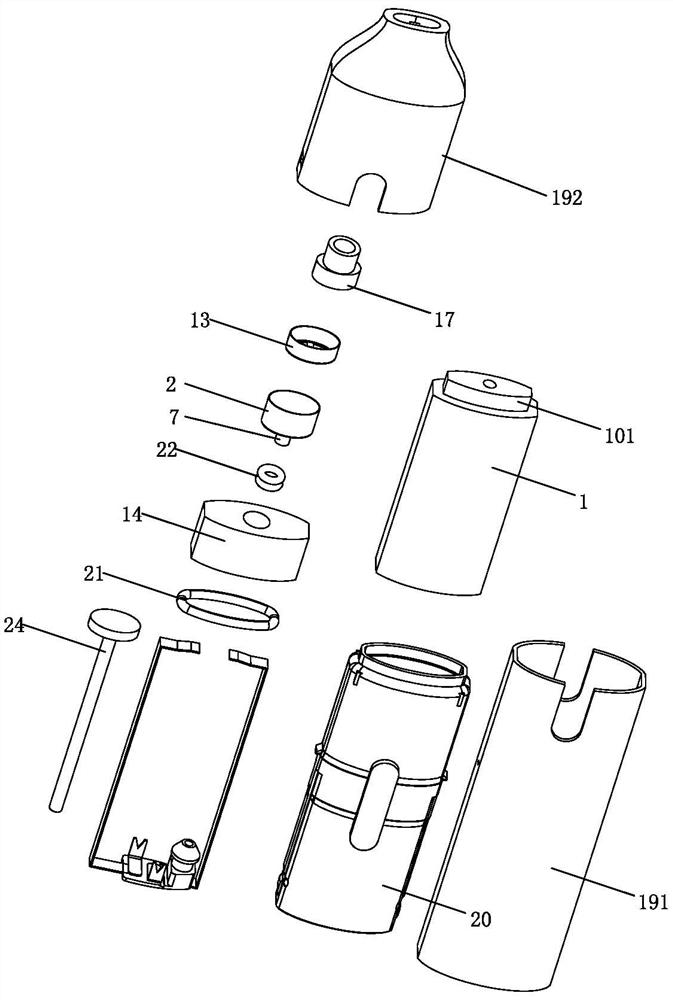

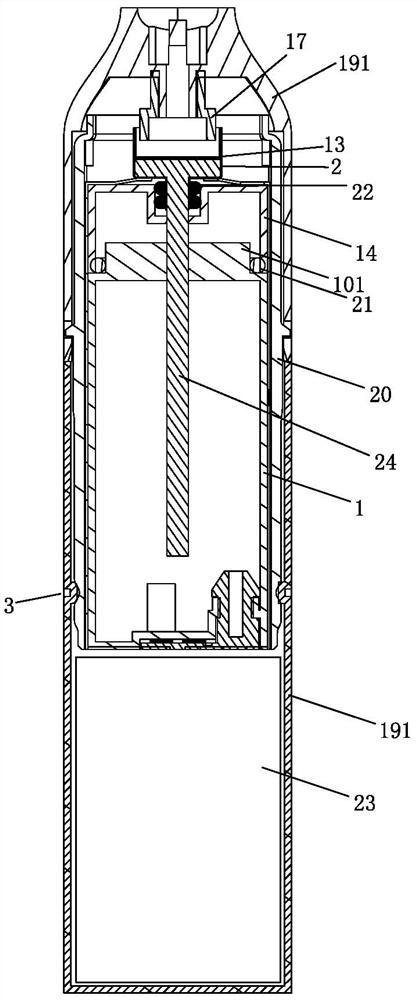

[0059] Please refer to Figure 1 to Figure 12 As shown, it shows the specific structure of various embodiments of the present invention. The atomizing device described in the present invention can be applied to products such as electronic cigarettes and medical atomizing devices; in this article, electronic cigarettes are taken as an example to describe in detail.

[0060] An atomization device that improves the atomization effect and prevents liquid leakage, comprising a liquid storage chamber 1, an atomization cup 2, an air inlet 3 and an air outlet pipe 4, wherein: the atomization cup 2 has an upper end opening, and the outlet The air pipe 4 extends into the atomizing cup 2 from the upper opening and maintains a gap with the inner bottom surface of the atomizing cup 2, and an air inlet channel 5 is formed between the outer circumference of the air outlet pipe 4 and the inner wall of the atomizing cup 2; The liquid in the chamber 1 enters the atomizing cup 2 and is heated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com