Vertical numerically-controlled lathe

A technology for CNC lathes and lathes, which is applied in the field of CNC lathes and can solve problems such as affecting the workpiece process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

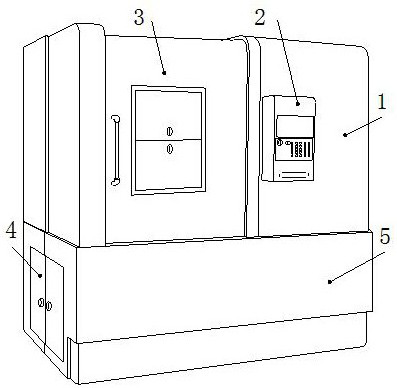

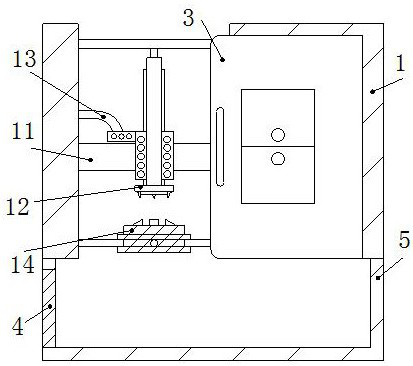

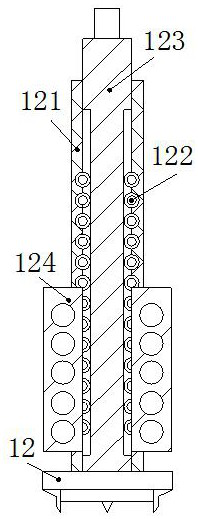

[0031] The present invention provides a vertical numerically controlled lathe, the structure of which comprises a lathe body 1, a control panel 2, a lathe door 3, an impurity removal cabinet 4, and a base 5, the bottom of the lathe body 1 is embedded and fixed on the upper surface of the base 5, and the control The plate 2 is installed on the front side of the lathe body 1, the lathe door 3 is connected to the front wall of the lathe body 1 through a gap, the impurity removal cabinet 4 is installed on the left side of the base 5, and the lathe body 1 includes a fixed frame 11, a tool 12. Control pipe 13, fixture 14, the left and right ends of the fixed frame 11 are respectively connected to the left and right inner walls of the lathe body 1 by welding, the tool 12 is connected to the front wall of the fixed frame 11 through a gap, and the end of the control pipe 13 is connected by bolts Connected to the left side of the tool 12, the outside of the bottom of the clamp 14 is conn...

Embodiment 2

[0037]The present invention provides a vertical numerically controlled lathe, the structure of which comprises a lathe body 1, a control panel 2, a lathe door 3, an impurity removal cabinet 4, and a base 5, the bottom of the lathe body 1 is embedded and fixed on the upper surface of the base 5, and the control The plate 2 is installed on the front side of the lathe body 1, the lathe door 3 is connected to the front wall of the lathe body 1 through a gap, the impurity removal cabinet 4 is installed on the left side of the base 5, and the lathe body 1 includes a fixed frame 11, a tool 12. Control pipe 13, fixture 14, the left and right ends of the fixed frame 11 are respectively connected to the left and right inner walls of the lathe body 1 by welding, the tool 12 is connected to the front wall of the fixed frame 11 through a gap, and the end of the control pipe 13 is connected by bolts Connected to the left side of the tool 12, the outside of the bottom of the clamp 14 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com