Fiber-reinforced guide eye and method for manufacturing fiber-reinforced guide eye

A fiber-reinforced, guide-eye technology, applied in fishing, animal husbandry, applications, etc., can solve the problems of increasing the overall weight of the fishing rod, increasing the throwing distance, affecting the hand feel, etc., to achieve a good fishing experience, improve strength and light weight, structure, etc. Simple and lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be explained with reference to specific embodiments. Those skilled in the art can understand that these embodiments are only used to illustrate the present invention, and they do not limit the scope of the present invention in any way.

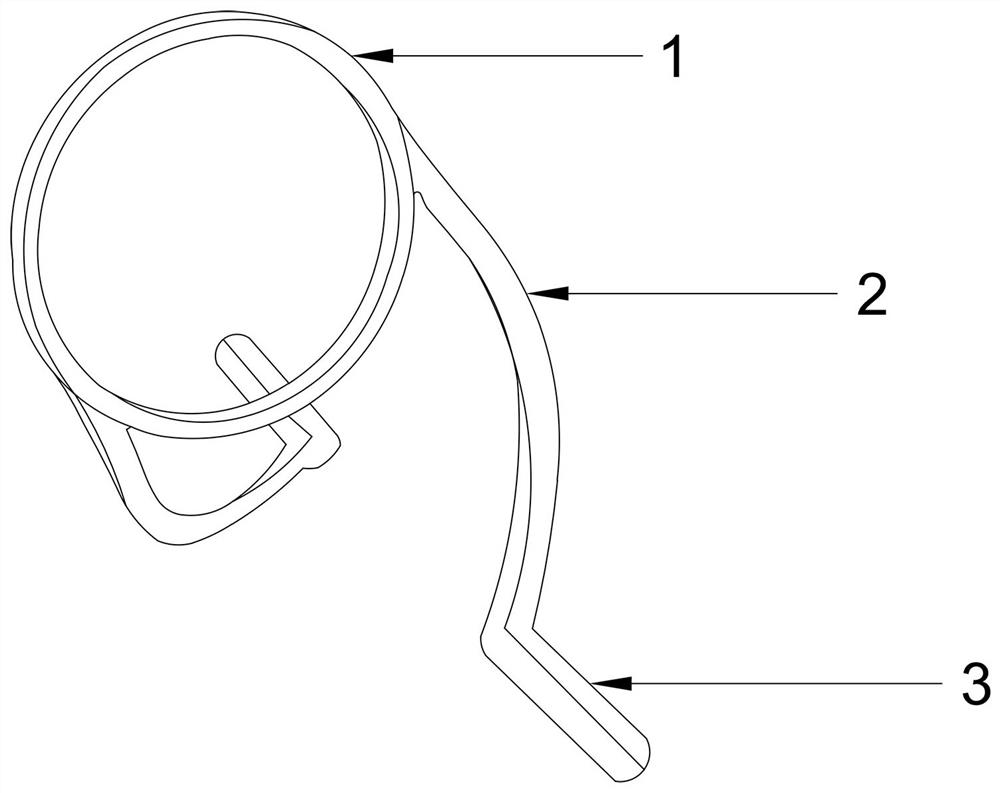

[0019] A fiber-reinforced guide eye and a method for manufacturing a fiber-reinforced guide eye, such as figure 1 with figure 2 As shown, the guide eye body is included. The guide eye body includes a bracket (2) and a fishing line guide ring fixing part (1); below the fishing line guide ring fixing part (1) are supported two side brackets; the bottom ends of the two sides of the bracket are connected and fixed Part (3); the brackets on both sides are divided into a first bracket and a second bracket; the fixing portion (3) includes a first fixing portion and a second fixing portion respectively connected to the first bracket and the second bracket.

[0020] The first bracket and the second bracket ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com