A kind of preparation method of polymer grade solvent isopentane

An isopentane, polymerization-grade technology used in the preparation of high-efficiency polymerized olefin solvents, which can solve problems such as unsatisfactory activity, stability and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

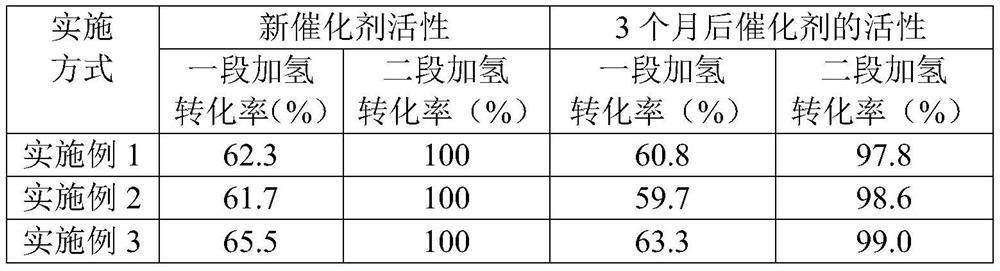

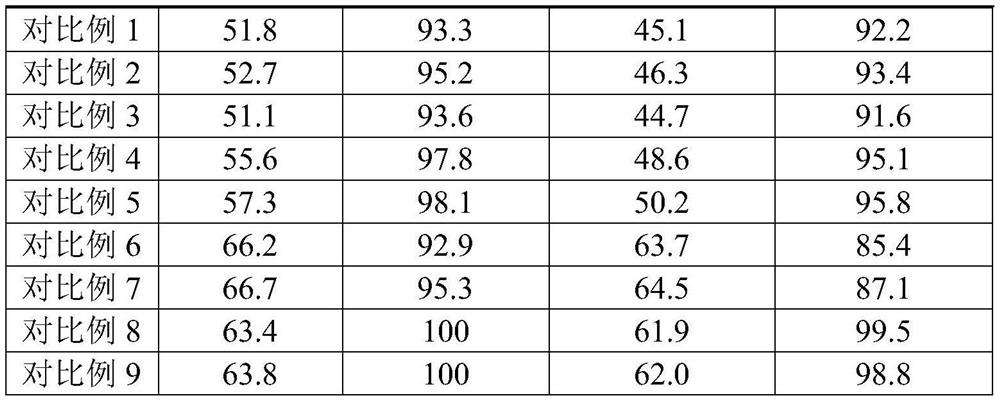

Examples

Embodiment 1

[0024] 1. Preparation of catalyst

[0025] 1. Preparation of nickel-based catalyst

[0026] Step 1: After wet ball milling 1 g of vanadium trioxide and 1 g of cobalt oxide for 3 hours, add 98 g of nickel oxide and continue wet ball milling for 10 hours to obtain a homogeneous mixture A of vanadium trioxide, cobalt oxide and nickel oxide.

[0027] Step 2: Dry the mixture A obtained in step 1 at 120°C for 2 hours, then sinter at 800°C for 5 hours, and finally grind it into nano-sized nickel-cobalt-vanadium-oxygen solid solution powder B.

[0028] Step 3: Take 1 g of nano-scale solid solution powder B obtained in step 2 and 99 g of powdered molecular sieve dry-milling for 5 hours and mix evenly, and finally granulate and reduce to obtain a nickel-based catalyst with nickel-cobalt-vanadium solid solution as the active component.

[0029] 2. Preparation of palladium-based catalyst

[0030] Step a: Add 200 g of 4-vinylphenylboronic acid into 250 ml of dried THF, disperse evenly, a...

Embodiment 2

[0040] 1. Preparation of catalyst

[0041] 1. Preparation of nickel-based catalyst

[0042] Step 1: After wet ball milling 2.5 g of vanadium trioxide and 2.5 g of cobalt oxide for 3 hours, add 95 g of nickel oxide and continue wet ball milling for 10 hours to obtain a homogeneous mixture A of vanadium trioxide, cobalt oxide and nickel oxide.

[0043] Step 2: Dry the mixture A obtained in step 1 at 120°C for 2 hours, then sinter at 1000°C for 5 hours, and finally grind it into nano-sized nickel-cobalt-vanadium-oxygen solid solution powder B.

[0044] Step 3: Take 2.5g of the nano-scale solid solution powder B obtained in step 2 and 97.5g of powdered molecular sieve dry mill for 5 hours and mix evenly, and finally granulate and reduce to obtain the nickel-based solid solution with nickel-cobalt-vanadium solid solution as the active component. catalyst.

[0045] 2. Preparation of palladium-based catalyst

[0046] Step a: Add 200 g of 4-vinylphenylboronic acid into 250 ml of dr...

Embodiment 3

[0056] 1. Preparation of catalyst

[0057] 1. Preparation of nickel-based catalyst

[0058] Step 1: After wet ball milling 5g of vanadium trioxide and 5g of cobalt oxide for 3 hours, add 90g of nickel oxide and continue wet ball milling for 10 hours to obtain a homogeneous mixture A of vanadium trioxide, cobalt oxide and nickel oxide.

[0059] Step 2: Dry the mixture A obtained in step 1 at 120°C for 2 hours, then sinter at 1200°C for 5 hours, and finally grind it into nano-sized nickel-cobalt-vanadium-oxygen solid solution powder B.

[0060] Step 3: Take 5g of the nano-scale solid solution powder B obtained in step 2 and 95g of powdered molecular sieve dry-milling for 5 hours and mix evenly, and finally granulate and reduce to obtain a nickel-based catalyst with nickel-cobalt-vanadium solid solution as the active component.

[0061] 2. Preparation of palladium-based catalyst

[0062] Step a: Add 200 g of 4-vinylphenylboronic acid into 250 ml of dried THF, disperse evenly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com